Common types of ice probes and sensors in commercial ice machines include water level sensors, ice thickness probes, bin level sensors, and temperature sensors. These components ensure proper ice formation, machine efficiency, and automatic shutoff.

-10%

-10%

-8%Alto-Shaam SN-38111 RTD ELAN CC34488 Control ProbeSpecial Price $155.00 Regular Price $169.00Out of stock

-8%Alto-Shaam SN-38111 RTD ELAN CC34488 Control ProbeSpecial Price $155.00 Regular Price $169.00Out of stock

-47%Manitowoc 2008029 Ice Thickness Control Probe, 5-1/2" X 3-1/4"Special Price $90.59 Regular Price $170.60

-47%Manitowoc 2008029 Ice Thickness Control Probe, 5-1/2" X 3-1/4"Special Price $90.59 Regular Price $170.60

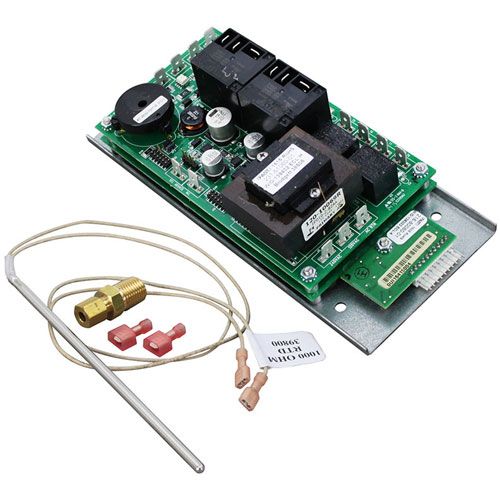

-32%Hoshizaki 3A3656-06 Ice Machine Controller W/ ProbesSpecial Price $586.93 Regular Price $865.95

-32%Hoshizaki 3A3656-06 Ice Machine Controller W/ ProbesSpecial Price $586.93 Regular Price $865.95- -9%Kold Draft 102145701 Refrigerator Evaporator ProbeSpecial Price $87.87 Regular Price $96.49Out of stock

Commercial Ice Machine Probes and Sensor Components

In the commercial ice machine industry, precision parts are critical for consistent performance, and one essential component is the ice thickness probe. Without it, ice makers may produce irregular or incomplete ice, leading to inefficiency and waste. Alongside thickness probes, other important components include ice sensors, bin controls, float switches, water level sensors, and thermistors.

Ice probes and sensors provide real-time feedback to the machine’s control system, regulating water levels, detecting bin capacity, and monitoring internal temperatures. By automatically adjusting cycles, they help maintain consistent ice production and energy efficiency while preventing machine overflows or shutdowns. In commercial kitchens, bars, and restaurants where a steady supply of ice is critical for beverages, food storage, and presentation, keeping these components in top condition ensures reliable service and reduces costly downtime.

At PartsFe, we offer a wide range of ice thickness probes and related parts, including temperature sensors rated up to 100°C, bin level sensors with capacities from 100 lbs. to 300 lbs., water level probes with 24V and 120V options, and replacement float switches built for heavy-duty cycles. Our inventory includes compatible parts for leading brands like Hoshizaki, Manitowoc, Scotsman, and Ice-O-Matic.

FAQs

Why is my ice machine producing thin or incomplete ice cubes?

This issue often points to a malfunctioning ice thickness probe that may not be detecting the proper ice size. Cleaning or replacing the probe usually resolves the problem.

What causes my ice machine to stop making ice suddenly?

Faulty ice probes and sensors can send incorrect signals, shutting down the machine. Checking connections and sensor functionality can help identify the cause.

My ice machine keeps running but makes no ice. What should I check?

Inspect the water level sensor and thickness probe. If they fail, the system won’t detect proper conditions to start ice formation.

Where can I find high-quality ice machine ice probes & sensors for top commercial brands?

You can find high-quality Ice Probes & Sensors for top commercial ice machine brands in the replacement parts category at PartsFe, offering components for Hoshizaki, Manitowoc, Scotsman, and Ice-O-Matic units.

How do I know if my ice probe needs replacement?

If ice is consistently irregular in size, melts too quickly, or harvest cycles are interrupted, it’s likely time to replace the probe.

Can cleaning sensors fix most ice machine errors?

Yes, mineral buildup often interferes with sensors. A thorough cleaning with manufacturer-recommended solutions can restore normal performance before replacement is necessary.