Common types of pilot safety valves for commercial deep fryers include combination gas valves, millivolt safety valves, and manual reset valves, each designed to control gas flow and ensure safe operation.

-47%Vulcan Hart 00-498158 Range NAT/LP Gas Pilot Safety Valve 1/4" FPTSpecial Price $295.56 Regular Price $554.57

-47%Vulcan Hart 00-498158 Range NAT/LP Gas Pilot Safety Valve 1/4" FPTSpecial Price $295.56 Regular Price $554.57

-35%Southbend 1166004 Range Double Pilot Tube Fitting 3/16"Special Price $18.35 Regular Price $28.03

-35%Southbend 1166004 Range Double Pilot Tube Fitting 3/16"Special Price $18.35 Regular Price $28.03

Pilot Safety Valve Replacement Parts for Commercial Grills

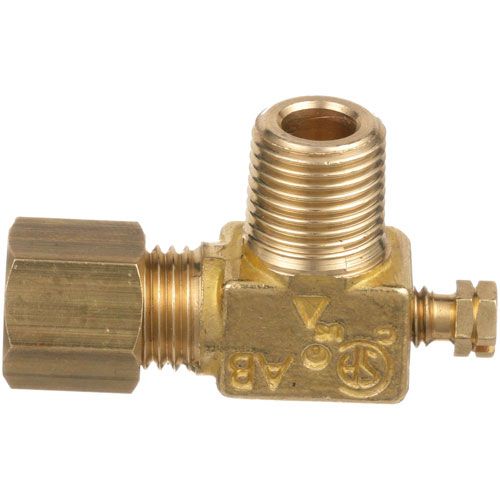

In commercial kitchens, precise flame control is critical for the safe and efficient operation of fryers, ranges, ovens, broilers, and griddles. A pilot safety valve is a key component that ensures raw gas does not enter the cookline if ignition fails, helping maintain both safety and consistent cooking performance. Along with the valve itself, related parts include pilot burners, thermocouples, thermopiles, gas regulators, and burner valves.

A gas pilot safety valve works by integrating with a thermocouple or thermopile to sense the pilot flame and allow gas to flow only when a flame is verified. If the flame is extinguished, the valve automatically shuts off gas supply to prevent hazardous buildup. A pilot-operated safety valve goes further by using pilot pressure to actuate the main valve mechanism, ensuring stable downstream gas flow under varying temperature and load demands. Signs that a replacement may be needed include frequent pilot outages, delayed burner ignition, or inconsistent fryer oil recovery, all of which can impact food quality and increase operating costs.

At PartsFe, you’ll find a wide range of pilot safety valves and related components, including valve coils rated at 24V and 120V, thermocouples with lengths from 24" to 48", universal tubing kits with 1/4" flare fittings, and heavy-duty regulators capable of handling up to 1/2 PSI. We stock trusted brands such as Pitco, Frymaster, Vulcan, and Garland.

FAQs

Can a pilot safety valve be cleaned, or should it be replaced?

Light cleaning of accessible debris is possible, but most faults require replacement. Internal wear or damage cannot usually be repaired effectively.

How often should pilot safety valves be inspected in food service equipment?

Inspect at least once a year, or more often for high-volume kitchens. Regular checks ensure safe gas control and prevent costly downtime.

Are pilot safety valves the same for all commercial fryers?

No, sizes, fittings, and configurations vary by fryer brand and model. Always match specifications before purchasing a replacement.

How do I know if my pilot safety valve is faulty?

If the pilot flame won’t stay lit or gas flow stops unexpectedly, the valve may be failing. Testing with a multimeter or technician inspection can confirm.

What causes a pilot safety valve to stop working?

Common causes include worn thermocouples, dirt buildup, corrosion, or internal spring failure. Overheating and improper maintenance also shorten its life.

Where can I find high-quality grill & griddle pilot safety valves for top commercial brands?

You can find high-quality Grill & Griddle Pilot Safety Valves for top commercial brands at PartsFe. Explore a wide selection designed for precise fit and safe gas control.