-2%Turbo Air 30281L0100 SD Door Switch, 1.5A/125VAC, 5A/250VACSpecial Price $49.98 Regular Price $51.00

-2%Turbo Air 30281L0100 SD Door Switch, 1.5A/125VAC, 5A/250VACSpecial Price $49.98 Regular Price $51.00

-2%Turbo Air TRBA19-14613 SD Door Switch, 1.5A/125VAC, 5A/250VACSpecial Price $49.98 Regular Price $51.00

-2%Turbo Air TRBA19-14613 SD Door Switch, 1.5A/125VAC, 5A/250VACSpecial Price $49.98 Regular Price $51.00

-17%Turbo Air 30283K0110 Thermostat, 3°F to -15°F Temperature ControlSpecial Price $168.54 Regular Price $204.04

-17%Turbo Air 30283K0110 Thermostat, 3°F to -15°F Temperature ControlSpecial Price $168.54 Regular Price $204.04

-20%Turbo Air 30200Q1200 Refrigerator Compressor ReplacementSpecial Price $722.86 Regular Price $905.84

-20%Turbo Air 30200Q1200 Refrigerator Compressor ReplacementSpecial Price $722.86 Regular Price $905.84

-57%Turbo Air P0189R0400 Refrigerator Compressor ReplacementSpecial Price $452.25 Regular Price $1,055.95

-57%Turbo Air P0189R0400 Refrigerator Compressor ReplacementSpecial Price $452.25 Regular Price $1,055.95

-45%Turbo Air P995200200 Commercial Refrigerator Door Switch 1.5" X 2.13"Special Price $30.42 Regular Price $54.95

-45%Turbo Air P995200200 Commercial Refrigerator Door Switch 1.5" X 2.13"Special Price $30.42 Regular Price $54.95

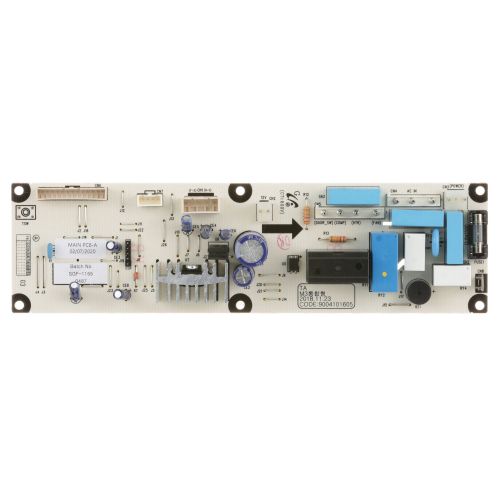

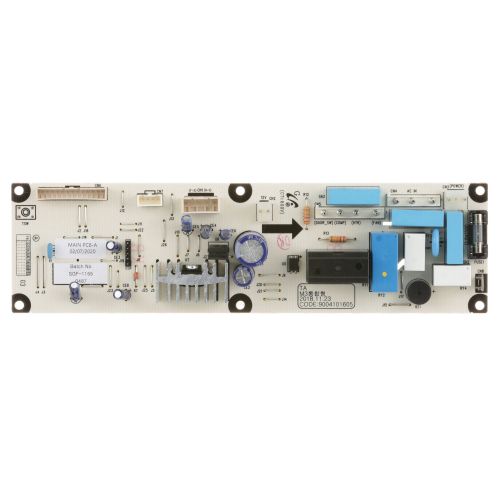

Turbo Air Compressor Parts

In order to maintain correct temperature control and protect the freshness and quality of perishable goods, Turbo Air compressor parts are crucial parts of Turbo Air refrigeration systems. The refrigeration system's heart, the compressor, may malfunction if one component breaks, thereby causing product loss and a loss of revenue for enterprises.

Compressor motor, relay, overload protection, start capacitor, and compressor crankcase heater are a few typical Turbo Air compressor parts. Together, these components maintain the compressor operating effectively and dependably.

An essential part of the Turbo Air compressor is the start capacitor. The compressor motor may have trouble starting up without a working start capacitor, and it could eventually break down.

In low-temperature situations, the crankcase heater acts as a heating element to keep the refrigerant oil warm and prevent it from hardening and clogging the compressor. When the motor is consuming too much current, the overload protector and relay are intended to cut off the power.

Genuine Turbo Air compressor parts must be used to ensure the refrigeration system is operating properly and to prevent any potential safety risks.

Routine maintenance can increase the compressor's lifespan and help avoid expensive maintenance by replacing worn-out or broken parts. PartsFe provides the finest customer service, the highest quality, the best pricing, and a safe payment method for replacement parts for Turbo air compressors.

FAQ’S

Can I change the parts on a Turbo Air compressor by myself?

It is not advised to try replacing Turbo Air compressor parts on your own unless you have the abilities and know-how to do so securely and successfully. For any repairs or replacements, they advised it to seek the advice of a qualified expert to guarantee correct installation and prevent potential safety issues.

How frequently should I have my turbo air compressor's oil changed?

The amount of oil consumed, the compressor's working circumstances, and the manufacturer's recommendations will all affect how frequently a turbo air compressor needs to have its oil changed. To ensure the equipment performs at its best and lasts as long as possible, it is crucial to adhere to the manufacturer's recommendations for oil changes.

The majority of manufacturers recommend that we change the oil of a turbo air compressor every 1,000 to 2,000 hours of operation, or every 6 to 12 months, whichever comes first. Nevertheless, this can change based on the particular compressor and its usage.

Turbo Air Manufacturers Other Categories

| Turbo Air Parts | Turbo Air Refrigerator Parts | Turbo Air Freezer Parts | Turbo Air Cooler Parts |