Saniserv manufactures soft serve ice cream machines, frozen yogurt machines, shake mixers, and frozen beverage dispensers. These consistent, easy-to-use appliances help kitchens serve frozen treats fast.

Saniserv Commercial Soft Serve Machines Replacement Parts

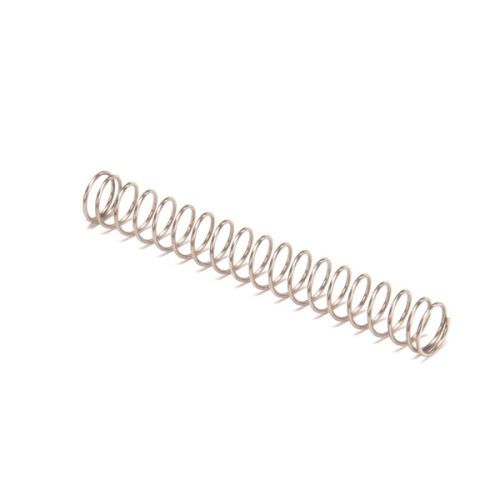

Saniserv is a trusted manufacturer in the food service industry, known for producing high-quality commercial frozen dessert equipment. Their product line includes soft serve machines, shake mixers, frozen beverage dispensers, and other specialty machines commonly used in commercial kitchen environments. These appliances are designed for efficiency, consistency, and simplicity, making them ideal for high-demand food service operations. Over time, the performance of these machines heavily depends on the condition of their components, especially ice cream machine parts like beater bars, gaskets, agitators, and motors. Each part plays a vital role, beater bars mix the product to a smooth consistency, while agitators maintain even freezing, and seals prevent leaks that could lead to product loss or contamination. With regular use, these parts experience natural wear and tear, which can cause issues like inconsistent texture, increased noise, or even complete equipment failure if not addressed. Recognizing early signs of wear, such as cracks in gaskets or reduced mixing efficiency, is crucial to avoiding service disruptions. Timely replacement of worn-out parts ensures optimal machine performance and helps extend the life of your equipment. Key components like motor assemblies, shaft seals, and mixing blades are often replaced to maintain peak functionality. For trusted Saniserv parts, PartsFe is your authorized source, offering convenient online shopping, swift delivery, and expert support. Experience quality assurance and more when you choose us for your Saniserv component needs.

FAQs

What types of parts are available for the Saniserv 407 and 707 models?

Saniserv 407 and 707 parts include essential components like beater bars, seals, drive shafts, and O-rings, which are necessary to maintain efficient soft serve operation.

How often should I replace Saniserv DF200 or 401 parts?

Parts such as scraper blades, gaskets, and brushes in Saniserv DF200 and 401 machines should be inspected regularly and replaced every 3 to 6 months, depending on usage, to ensure consistent performance.

Are Saniserv 501 and 707A parts interchangeable with other models?

Some parts may be compatible across models, but it's important to check model-specific part numbers. The 501 and 707A models have unique design features requiring specific OEM components.

What are the common signs that my Saniserv A4011N or A4071E parts need replacing?

Look for signs like reduced freezing efficiency, unusual noises, leaking mix, or inconsistent product texture. These indicate parts like motors, seals, or bearings may be worn out.

Where can I buy authentic Saniserv A5011P parts online?

You can find trusted Saniserv A5011P parts at PartsFe, offering a wide selection of OEM replacements with fast shipping and expert support for commercial kitchen needs.

Find me the most common Saniserv replacement parts.

The most common Saniserv replacement parts include beater bars, scraper blades, seals, drive shafts, and agitators. These parts are essential for consistent product quality. Regular replacement helps maintain peak performance in commercial food service operations.

How to fix a SaniServ soft serve machine that won't freeze?

If your SaniServ soft serve machine isn’t freezing, start by checking the mix level and ensuring the machine is in “AUTO” mode. A faulty thermostat, compressor, or beater motor could be the issue. Inspect these components and replace any worn parts to restore proper freezing.

What’s the solution for a worn SaniServ clutch?

A worn SaniServ clutch can cause the beater shaft to slip or stop turning. The solution is to inspect the clutch for wear or damage and replace it with a genuine OEM part. Proper installation and alignment are critical to ensure smooth operation after replacement.