Future of Kitchen Ventilation: Cutting-Edge Restaurant Hood Systems

The kitchen is the heart of a restaurant, where creativity meets efficiency, and culinary masterpieces are created. But behind every successful meal is a crucial, often-overlooked element of the kitchen: ventilation. Traditional kitchen hoods have long been the standard, extracting heat, grease, and odors. However, as restaurants push the boundaries of culinary experiences and sustainability, ventilation systems are evolving into highly sophisticated, energy-efficient solutions that promise cleaner air, improved performance, and even smarter integration with technology.

In this article, we’ll explore the future of kitchen ventilation, focusing on the cutting-edge restaurant hood systems that are reshaping the culinary landscape. From smart controls to energy-saving innovations, the latest developments in commercial kitchen hoods are ushering in a new era of kitchen air quality, performance, and sustainability.

The Evolving Role of Ventilation in Modern Kitchens

Historically, the role of kitchen ventilation was purely functional — to remove smoke, heat, odors, and airborne grease. As restaurant kitchens have evolved into high-tech environments, the need for better ventilation solutions has increased significantly. High-powered stoves, open flames, and intricate cooking processes all contribute to indoor air quality problems. Traditional hoods, with their large exhaust fans and filter systems, often fail to meet modern demands in terms of efficiency, energy use, and noise reduction.

Today, the demands on ventilation systems are more complex. There is an increasing focus on reducing energy consumption, minimizing environmental impact, and improving kitchen conditions for staff and customers. The future of kitchen ventilation, therefore, is driven by the integration of advanced technology and sustainable design principles.

Smart Kitchen Ventilation: The Rise of Automation

One of the most exciting developments in restaurant hood systems is the rise of smart ventilation technology. Smart systems use sensors and automation to adjust airflow based on real-time cooking conditions, resulting in better efficiency, reduced energy use, and improved air quality.

Sensor-driven ventilation is one of the key innovations. These sensors are designed to detect the temperature, humidity, and air quality in the kitchen. As cooking activities change throughout the day, the system automatically adjusts the ventilation settings to ensure optimal air quality. For example, if the kitchen is experiencing high heat levels due to a large number of ovens or grills in use, the system will increase the airflow to remove the heat. When the kitchen quiets down, the system can reduce the airflow to save energy. This automation results in a significant reduction in energy costs and a better working environment for the kitchen staff.

Moreover, airflow control systems allow operators to program the ventilation system to respond to specific needs. For instance, more ventilation might be required during peak hours when cooking activity is at its highest, while a quieter operation might be desired during slower hours. Smart systems can also be monitored and controlled remotely via mobile apps, enabling restaurant managers to keep tabs on their kitchen’s performance and address issues before they become a problem.

Also read on: Robots to Analytics: 2025 Tech Trends That Reshape Restaurants

Energy-Efficiency and Sustainability in Ventilation

Sustainability is increasingly a priority for the restaurant industry, not only because of environmental concerns but also due to the rising costs of energy and stricter regulatory standards. Kitchen ventilation, which has traditionally been a major energy consumer, is now a focal point for energy-saving innovations.

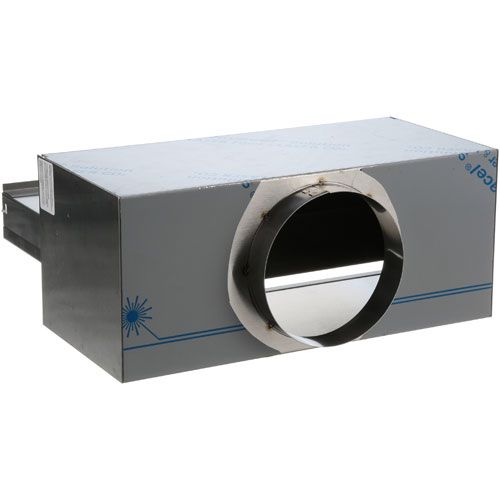

Demand-controlled ventilation (DCV) is one such solution gaining traction. DCV uses sensors to monitor kitchen activity and adjust the ventilation system's power accordingly. The system can reduce the exhaust fan speed when cooking volume is low, and ramp it up during peak cooking times. This ensures that the kitchen is always properly ventilated without wasting unnecessary energy.

Heat recovery systems are another energy-efficient advancement. These systems capture and reuse the heat from the kitchen exhaust air to preheat water or supply the HVAC system with heated air. This reduces the need for additional energy to heat water or air, providing a significant cost-saving opportunity. By recycling heat that would otherwise be wasted, heat recovery units reduce the overall carbon footprint of the restaurant and contribute to a more sustainable operation.

Furthermore, energy-efficient LED lighting integrated into hoods and ventilation systems reduces the energy consumption of the entire setup. These lights not only consume less power but also produce less heat, contributing to a cooler and more comfortable kitchen environment.

Advanced Filtration: Cleaner Air and Healthier Kitchens

Traditional restaurant hoods often rely on mechanical filtration methods to remove grease and particles from the air. However, advancements in filtration technology have led to cleaner, more effective air purification solutions. High-efficiency particulate air (HEPA) filters, which capture 99.97% of airborne particles, are now being integrated into commercial kitchen ventilation systems. These filters provide superior air quality by trapping harmful particles, including grease, dust, and bacteria, which can improve the health and safety of kitchen staff.

Another important development in filtration technology is electrostatic precipitators (ESPs), which charge particles in the exhaust air to remove grease, smoke, and particulate matter. These systems are highly effective in reducing kitchen odors and airborne pollutants, creating a healthier work environment.

Odor-neutralizing technologies are also gaining popularity. These systems use chemical scrubbers, activated carbon filters, or ozone generators to eliminate odors at the source. Instead of merely masking odors, these advanced filtration systems neutralize them, ensuring that the kitchen air remains fresh and clean.

Also read on: CleanCold Technology: A Game Changer in Commercial Refrigeration

Noise Reduction and Aesthetics

The noise generated by traditional ventilation systems, particularly those with large exhaust fans, is a common complaint in restaurant kitchens. High noise levels can lead to increased stress and fatigue for kitchen staff, while also disturbing the dining experience for customers in open kitchen settings.

Innovative hood designs are now incorporating sound-dampening technologies to reduce the noise produced by the exhaust system. These designs use quieter, more efficient fans and acoustic barriers to reduce noise levels without sacrificing performance. Additionally, sleek and modern aesthetic designs are becoming a priority. Restaurant owners want their kitchen hoods to blend seamlessly with the overall design of their establishments. The future of kitchen hoods promises a fusion of functionality, design, and noise reduction, ensuring that both the kitchen and dining areas are visually and acoustically appealing.

The Integration of IoT and Data Analytics

As restaurants move toward more data-driven operations, the integration of the Internet of Things (IoT) into kitchen ventilation systems is a natural evolution. IoT-enabled hoods can collect real-time data on air quality, temperature, humidity, energy consumption, and equipment performance. This data can be analyzed to identify trends, predict maintenance needs, and optimize ventilation settings for maximum efficiency.

For example, predictive maintenance is an emerging trend that uses data from IoT-connected systems to forecast when ventilation components will need service or replacement. By anticipating issues before they occur, restaurants can avoid costly repairs and downtime.

Additionally, data analytics can provide insights into kitchen operations that help managers make informed decisions about energy consumption, labor scheduling, and menu planning. These insights allow for a more streamlined, cost-efficient, and environmentally friendly kitchen operation.

The Future of Kitchen Ventilation: Looking Ahead

The future of kitchen ventilation is one of innovation, efficiency, and sustainability. Cutting-edge restaurant hood systems are becoming smarter, quieter, and more energy-efficient, providing an improved experience for both kitchen staff and restaurant guests. From sensor-driven automation and advanced filtration systems to energy recovery technologies and the integration of IoT, the ventilation systems of tomorrow will be more adaptive and capable of meeting the unique challenges faced by modern commercial kitchens.

As the restaurant industry continues to evolve and embrace new technologies, the importance of ventilation will only increase. A healthy, energy-efficient, and well-ventilated kitchen is not just a regulatory requirement—it’s a critical element in the pursuit of culinary excellence, sustainability, and customer satisfaction. The future of kitchen ventilation has arrived, and it’s changing the way we cook, breathe, and enjoy food.

By investing in these cutting-edge systems, restaurant owners can ensure that their kitchens are equipped to meet the demands of the future, creating a cleaner, healthier, and more efficient environment for everyone involved.

PartsFe offers a wide selection of high-quality commercial restaurant equipment parts, including refrigeration components, dishwashers, ice makers, and oven parts. With fast shipping and competitive prices, you can easily find the exact parts you need to keep your kitchen running smoothly. Shop online for reliable replacements and keep your equipment in top condition. Trust PartsFe for all your restaurant equipment parts needs!

FAQs

How does commercial kitchen ventilation work?

It removes heat, smoke, grease, and odors using exhaust hoods, ducts, and fans, ensuring clean air and a safe environment.

What is a hood system in a restaurant?

A hood system is a ventilation setup that captures and expels cooking fumes, ensuring air quality and compliance with safety standards.