How to Maintain and Replace Ice Machine Water Pump

The longevity and optimal performance of your ice machine water pump depend on timely replacement and proper maintenance. Water must be circulated throughout the system to effectively produce ice, and this is where an ice machine water pump comes into play. But as time goes on, the pump may develop wear and tear, which could result in decreased performance, possible malfunctions, and higher maintenance expenses. Regular maintenance increases the ice maker's overall reliability, in addition to helping to identify and address minor issues before they worsen.

About maintaining and replacing the water pump in your ice maker, this guide offers comprehensive insights. From routine cleaning and inspection to pump replacement instructions, you will learn how to keep your equipment in top condition. Whether you're a facility manager, a restaurant owner, or a maintenance technician, understanding these processes will help you prevent downtime and ensure your ice machine operates smoothly and efficiently.

| Table of contents: The significance of the commercial ice machine water pump Importance of maintaining water pumps in ice machines Maintenance practices & replacement signs for ice machine water pumps Price ranges for various brands of ice machine water pumps How to fix an ice maker water pump that doesn't work after replacing it |

The significance of the commercial ice machine water pump

A commercial ice machine water pump is indispensable in maintaining the efficiency and longevity of any ice-making device. Whether used in restaurants, hotels, or hospitals, this essential component, also known as an ice machine pump, plays a pivotal role in ensuring smooth operation and high-quality ice production. Here’s why the ice machine water pump is so significant:

Efficient ice production:

- Circulation of water: The water pump for ice machines circulates water over the evaporator plate, where it freezes to form ice.

- Consistency and quality: An ice machine with pump ensures even water distribution, producing clear and high-quality ice cubes.

- Reliable brands: Brands like Hoshizaki, Manitowoc, Scotsman, and Vevor offer pumps known for their efficiency.

Preventing overheating:

- Temperature regulation: The cold water pump keeps the machine operating within its optimal temperature range by moving water continuously.

- Protecting components: This prevents the machine from overheating, which can damage internal parts and reduce efficiency.

Maintaining cleanliness:

- Minimizing buildup: Continuous water movement helps reduce the accumulation of minerals and impurities that can clog the system.

- Ensuring safety: It keeps the ice clean and safe, which is crucial for food service and healthcare environments.

Extending machine lifespan:

- Reducing strain: Proper water flow facilitated by the ice pump reduces the strain on the compressor and evaporator.

- Longevity: Fewer breakdowns and a longer operational life when the pump is functioning well.

- Timely replacement: Using high-quality replacement parts like a Hoshizaki ice machine water pump, Manitowoc ice machine water pump, or universal ice machine water pump can prolong machine life.

Meeting commercial demands:

- Handling high usage: Commercial ice maker installations require pumps that can withstand rigorous, continuous use.

- Durability and cost-effectiveness: Vevor ice machine water pumps are notable for their durability and cost-effectiveness, making them suitable for commercial settings.

Specialized pumps for specific needs:

- Condensate pumps are essential for models that produce excess condensation.

- Drain pumps: An ice maker with drain pan efficiently manages drainage, preventing operational issues.

Regular maintenance:

- Inspection and cleaning: Regular maintenance, including inspection and cleaning, helps in the early detection of issues and ensures the pump operates efficiently.

- Ice Maker pump replacement: Timely replacement of the ice maker water pump is crucial to prevent unexpected breakdowns.

Enhanced efficiency and performance:

- Optimal operation: This ensures the ice machine operates efficiently, reducing energy consumption and operational costs.

- Consistent performance: Regular maintenance and high-quality pumps ensure consistent ice production, meeting customer demands without interruption.

The commercial ice machine water pump is integral to the overall performance and reliability of the ice-making process. By ensuring efficient ice production, preventing overheating, maintaining cleanliness, extending machine lifespan, and meeting the rigorous demands of commercial use, this component plays a crucial role. Whether you need a cold water pump, a condensate pump for an ice maker, or a universal ice machine water pump, understanding its significance helps maintain and replace it effectively, ensuring uninterrupted ice production and high-quality ice.

Importance of maintaining water pumps in ice machines

To ensure your ice maker's long-term functionality and optimal performance, routine maintenance on the water pump is imperative. Maintaining the ice machine pump, whether it is a cold water pump, condensate pump for an ice maker, or any other type, is essential to keeping your equipment operating properly, whether you have a residential or commercial ice maker installation. This is why routine upkeep is so important:

Regular maintenance of the ice machine water pump is essential for optimizing performance, preventing costly repairs, extending equipment lifespan, improving ice quality, enhancing energy efficiency, reducing the risk of unexpected failures, and ensuring compliance and safety. Whether you have a universal ice machine water pump or a specific brand like a Scotsman ice machine or a Vevor ice machine, keeping up with maintenance practices will ensure your ice machine operates efficiently .

Maintenance practices & replacement signs for ice machine water pumps

Maintaining the ice machine water pump is critical for ensuring the optimal performance and longevity of your ice machine. Whether you have a cold water pump, a condensate pump for an ice maker, or any other type of ice machine pump, routine maintenance helps prevent issues and keeps the equipment running smoothly. However, even with regular care, there are times when replacement is necessary. Here’s a guide to routine maintenance procedures and how to recognize when an ice machine pump replacement is needed.

Routine maintenance practices:

Regular inspections:

- Visual check: Inspect the ice machine water pump and surrounding components for any signs of wear, leaks, or damage. Pay attention to connections, hoses, and fittings. For pumps such as the Hoshizaki ice machine water pump or Manitowoc ice machine water pump, ensure that all parts are secure and intact.

- Performance check: Monitor the ice machine’s performance regularly. Ensure that the water flow is consistent and that the machine is producing ice at the expected rate.

Cleaning:

- Pump cleaning: Clean the ice machine pump and its components to remove any debris, scale, or mineral build-up. Use the appropriate cleaning solutions recommended by the manufacturer. For a cold water pump or condensate pump in an ice maker, regular cleaning helps prevent clogs and maintain efficient water flow.

- Machine interior: Clean the interior of the ice machine, including the evaporator plate and water reservoir. This helps prevent contamination and maintains high ice quality.

Testing:

- Operational test: Run the ice machine and observe the pump’s operation. Ensure that it starts, stops, and operates smoothly without unusual noises or vibrations. For pumps like the universal ice machine water pump, proper testing is essential to ensure that it is functioning as intended.

- Water flow test: Check the water flow rate to ensure it meets the specifications for your ice machine. Inconsistent flow may indicate issues with the pump or associated components.

Replacing worn parts:

- Identifying worn parts: During inspections, identify any components that are worn or damaged, such as seals, gaskets, or impellers. Regularly replacing these parts helps prevent further damage to the pump.

- Scheduled replacements: Follow the manufacturer’s guidelines for replacing parts. For example, if using a Vevor ice machine or a Scotsman ice machine, adhere to their recommended maintenance schedules for part replacements.

Recognizing when replacement is necessary

Unusual noises:

- Signs: If the ice machine pump starts making grinding, buzzing, or rattling noises, it could be a sign of internal damage or wear. This is particularly concerning if it persists despite regular maintenance.

- Action: An ice maker pump replacement might be necessary if these noises indicate significant damage or malfunction.

Reduced ice production:

- Signs: Noticeable decreases in ice production or poor ice quality can indicate that the pump is not functioning efficiently. For instance, if the ice maker with drain pump is producing less ice or the ice is irregular in shape, it might be a sign of pump issues.

- Action: Evaluate the performance of the ice machine pump and consider replacing it if maintenance doesn’t resolve the production issues.

Water leaks:

- Signs: Persistent water leaks around the pump area can be indicative of seal failure, cracks, or other issues. This can lead to water damage and reduced performance.

- Action: Check for leaks and replace the pump if the leaks are due to internal pump damage or extensive wear.

Frequent repairs:

- Signs: Frequent repairs are a clear indication that the pump is failing. If repairs become routine, it’s often more economical to replace the pump.

- Action: Consider an ice maker pump replacement if repairs are frequent and the cost of repairs approaches or exceeds the cost of a new pump.

Age of the pump:

- Signs: Pumps typically have a lifespan of 5-7 years. If your ice machine pump is within this age range and showing signs of wear, it might be time for a replacement.

- Action: Follow the manufacturer’s recommendations and replace the pump if it is reaching the end of its service life.

An ice machine water pump is essential for ensuring optimal performance, extending the life of the pump, and maintaining ice quality. Regular inspections, cleaning, and part replacements help keep the pump in good condition. Recognizing when replacement is necessary involves paying attention to signs like unusual noises, reduced ice production, water leaks, frequent repairs, and the pump’s age. By following these guidelines, you can ensure your ice machine continues to operate efficiently and effectively.

Refer: 5 Signs You Need To Replace Or Clean Your Ice Machine

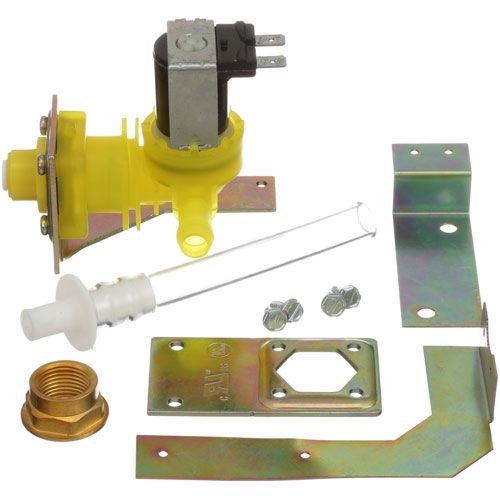

Price ranges for various brands of ice machine water pumps

When it comes to ice machine water pumps, several brands stand out in the market. Each brand offers unique features, varying in price and quality. Here’s a comparison of some popular brands:

|

Brand |

Key Features |

Price Range |

|

Hoshizaki ice machine water pump |

Durable, high performance, easy installation |

$100 - $200 |

|

Manitowoc ice machine water pump |

Efficient, reliable, and low maintenance |

$120 - $250 |

|

Scotsman ice machine water pump |

High efficiency, robust design, minimal noise |

$110 - $230 |

|

Vevor ice machine water pump |

Cost-effective, good build quality, versatile applications |

$80 - $150 |

|

Universal ice machine water pump |

Compatible with various ice machine models, easy replacement |

$90 - $170 |

Choosing the right brand and model depends on your specific needs, such as the type of ice machine and the environment in which it operates. PartsFe is a reliable source for purchasing these pumps, offering a range of options to suit different requirements.

How to fix an ice maker water pump that doesn't work after Replacing it

Replacing an ice maker water pump can sometimes result in issues where the new pump fails to operate as expected. This can be frustrating, especially in a commercial setting where a functioning ice machine is crucial. If you encounter problems with your ice maker pump, whether it’s a Hoshizaki ice machine water pump, a Manitowoc ice machine water pump, or a universal ice machine water pump, follow these troubleshooting steps to resolve the issue.

Recheck installation: The first step in troubleshooting an ice maker water pump that isn’t working is to ensure that it was installed correctly. Here’s what you should do:

- Verify connections: Make sure that all water lines and electrical connections are securely attached. A loose connection can prevent the pump from functioning. Check both the inlet and outlet connections of the water pump for the ice machine to ensure they are properly fitted.

- Inspect mounting: Ensure the ice machine pump is correctly mounted. Misalignment or improper mounting can cause operational issues. Verify that the pump is securely fixed in place and that no movement or vibration could impact its performance.

Check the power supply: Confirm that the ice machine is receiving power:

- Power source: Check if the ice machine is plugged in properly and that the power supply is functioning. Sometimes, a tripped circuit breaker or a blown fuse can interrupt the power to the pump. Reset the circuit breaker or replace the fuse if necessary.

- Electrical connections: Inspect the electrical connections to the new pump. Ensure that the wiring is correctly connected according to the manufacturer's specifications. Look for any signs of damaged wires or loose connections that could be affecting power delivery to the pump.

Inspect for obstructions: Obstructions can impede the operation of the water pump for ice machine:

- Check water flow: Ensure that there are no blockages in the water lines leading to or from the pump. Debris or scale build-up can obstruct water flow and prevent the pump from functioning. Clean any blockages in the lines and ensure proper water flow.

- Pump interior: If possible, inspect the interior of the pump for any obstructions or debris. Accumulated debris can hinder the pump's operation. Clean the internal components of the pump as needed.

Verify compatibility: Ensure that the replacement pump is compatible with your ice machine model:

- Model specifications: Check that the ice maker pump replacement is suitable for your specific ice machine model. Compatibility issues can lead to operational problems. Refer to the manufacturer’s specifications or consult with a technician to confirm that the new pump is appropriate for your machine.

- Pump type: Verify that the type of pump installed matches the requirements of your ice machine. For example, if your ice machine uses a cold water pump or a condensate pump for ice maker, ensure that the replacement matches these specifications.

Test water flow: Test the pump to ensure it is working correctly:

- Run diagnostics: Many ice machines have diagnostic modes that can help identify issues with the pump. Run the diagnostics to see if any error codes are reported related to the water pump.

- Manual test: If the machine allows, manually test the pump’s operation by activating it and checking if water is being pumped through the system. Ensure that water flow is consistent and as expected.

Consult the manufacturer’s manual: Refer to the manufacturer's manual for specific troubleshooting tips related to your ice machine and pump model:

- Troubleshooting section: The manual often includes a troubleshooting section that addresses common issues with the ice machine water pump. Follow the recommended procedures for resolving problems.

- Customer support: If you’re unable to resolve the issue, contact the manufacturer’s customer support for assistance. They can provide additional guidance or arrange for a technician to inspect the ice pump.

Consider professional assistance: If all else fails, seek help from a professional technician:

- Expert inspection: A qualified technician can conduct a thorough inspection of the ice machine and pump, identify any underlying issues, and recommend appropriate solutions.

- Repair or replacement: If the pump or other components are faulty, the technician can perform necessary repairs or recommend a suitable replacement.

Checkout: How To Clean Manitowoc Ice Machine?

Addressing issues with an ice maker water pump that doesn’t work after replacement involves rechecking installation, ensuring proper power supply, inspecting for obstructions, verifying compatibility, testing water flow, consulting the manufacturer’s manual, and seeking professional help if needed. By following these steps, you can diagnose and resolve issues with your ice machine pump, ensuring reliable ice production for your needs.

For reliable operation and to prevent expensive repairs, it is critical to maintain and replace the water pump in your ice maker. Regular maintenance, such as cleaning and inspecting the pump, can prevent common issues and extend the lifespan of your equipment. When it comes to replacement, following a structured approach will help you efficiently install a new pump and restore optimal functionality. Partsfe offers a comprehensive selection of ice machine parts, including water filters, door gaskets, and water pumps. By staying proactive with maintenance and using high-quality replacement parts, you can minimize downtime and ensure your ice machine remains a dependable asset to your operation

FAQs

Do I need an ice maker with drain pump?

Not necessarily. If your desired location for the ice maker has a dedicated drain positioned lower than the unit, a gravity drain system may suffice. However, if flexibility in placement is a priority, or your desired location lacks a suitable drain, an ice maker with drain pump is a valuable option.

What are common signs that an ice machine with pump needs replacement?

Common signs that your ice machine with pump may need replacement include unusual noises, reduced ice production, water leaks, or a noticeable decrease in efficiency. If you notice any of these issues, it’s important to check the pump and consider a replacement if necessary.

What is an ice maker with drain pump?

An ice maker with drain pump is a type of ice maker that incorporates a built-in pump to automatically remove excess water during the ice-making cycle. This eliminates the need for a gravity drain system, which requires the drain to be positioned lower than the ice maker itself.

When should I consider replacing my ice machine water pump?

Replace it if the pump fails to operate efficiently despite maintenance, or if it shows signs of significant wear or damage.