Troubleshooting Common Randell Refrigerator Problems in Commercial Kitchens

Randell refrigerators are trusted staples in many commercial kitchens due to their durability and performance. However, like any heavily used appliance, they can occasionally develop issues that disrupt operations and impact food safety. Understanding the most common problems that affect Randell units and how to troubleshoot them can help kitchen staff quickly resolve minor issues without calling for costly repairs. Whether it's inconsistent temperatures, unusual noises, or compressor malfunctions, early detection and proper handling are key to maintaining optimal performance. This guide will walk you through the typical problems encountered with Randell refrigerators, offering practical troubleshooting tips to minimize downtime and keep your kitchen running smoothly.

Understanding How a Randell Refrigerator Works

Randell refrigerators are designed specifically for the demanding conditions of commercial kitchens. These refrigerators typically use a forced-air Randell refrigeration system, which circulates cold air evenly throughout the cabinet to maintain consistent temperatures.

To properly troubleshoot and maintain a Randell refrigerator, it's essential to understand how it works and what its main components are:

-

Compressor: Functions as the core of the system, compressing the refrigerant gas and pushing it through the refrigeration cycle.

-

Condenser Coil: Typically located at the back or beneath the unit, it releases heat from the refrigerant as it transforms from gas to liquid.

-

Expansion Valve: Regulates how much refrigerant enters the evaporator coil, lowering its pressure and enabling it to cool effectively.

-

Evaporator Coil: Draws heat from the refrigerator’s interior, causing the refrigerant to evaporate and cool the air inside the unit.

-

Thermostat: Tracks the internal temperature and activates or shuts off the compressor to maintain the desired cooling level.

-

Fans: Circulate cold air evenly throughout the unit to maintain consistent temperatures.

-

Drain System: Removes condensation and prevents water buildup inside the refrigerator.

-

Insulation: Helps retain cold air within the unit and improves energy efficiency by reducing heat exchange with the external environment.

Understanding these parts and their roles can help you identify where issues might arise and how to address them effectively.

Having trouble finding the right parts for your refrigerator? PartsFe has you covered with essential components like evaporator fans, thermostats, and defrost heaters from leading brands like Danfoss, Emerson, and Copeland to help resolve common cooling problems. Get what you need quickly and keep your kitchen running without a hitch!

Common Signs Your Randell Refrigerator Needs Troubleshooting

Identifying early warning signs can help you resolve problems before they become serious. Watch for these common indicators that your Randell commercial refrigerator may need attention:

-

Temperature Fluctuations: The unit fails to maintain steady cooling, causing food to spoil or freeze inconsistently.

-

Ice or Frost Build-Up: Excessive ice forming inside the refrigerator or on the evaporator coils.

-

Water Leakage: Water collecting inside or around the unit, often due to clogged drain lines or drainage system problems.

-

Constant Compressor Operation: The compressor runs nonstop without cycling off, which can signal an underlying issue.

-

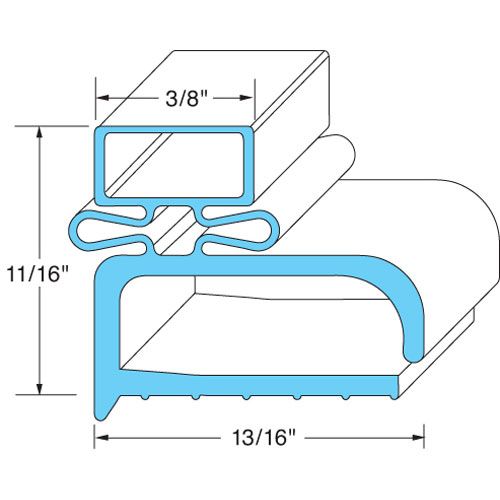

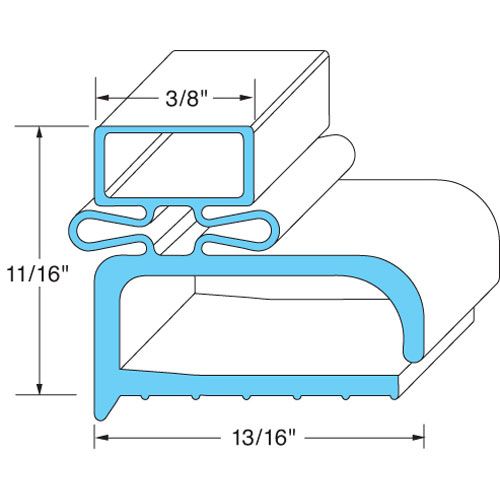

Damaged Door Seals: Worn, loose, or cracked gaskets that let cold air leak out, reducing cooling efficiency.

-

Fan Issues: Fans that are noisy, slow, or stop running, leading to uneven air circulation.

-

Warning Lights or Error Codes: Digital displays showing alerts indicating malfunctions.

Noticing any of these signs means it’s time to troubleshoot your Randell refrigerator parts to keep it running efficiently and protect your kitchen operations.

Key Factors Affecting Randell Refrigerator Performance in Commercial Kitchens

Several factors can impact how well a Randell refrigerator performs in the busy environment of a commercial kitchen. Knowing these details can help ensure peak performance and prolong the life of the unit.

-

Ambient Temperature: High kitchen temperatures or inadequate ventilation can cause the refrigerator to work harder, thereby reducing its efficiency.

-

Frequent Door Openings: Constantly opening the refrigerator door lets cold air escape and warm air enter, making it difficult to maintain stable temperatures.

-

Overloading: Packing the refrigerator too full restricts air circulation, causing uneven cooling and increased wear on the compressor.

-

Regular Maintenance: Lack of routine cleaning and upkeep, such as condenser coil cleaning and gasket inspections, can lead to reduced performance.

-

Proper Installation: Incorrect installation, such as improper leveling or insufficient clearance around the unit, can affect airflow and cooling efficiency.

-

Door Seal Condition: Worn, loose, or cracked Randell refrigeration gaskets that let cold air leak out, reducing cooling efficiency.

-

Power Supply Stability: Fluctuations or interruptions in power can affect compressor function and overall refrigeration performance.

-

Drainage Issues: Blocked or damaged drains can cause water buildup and affect humidity control inside the unit.

-

Refrigerant Levels: Insufficient or leaking refrigerant lowers cooling efficiency and puts extra strain on the compressor.

Keeping these factors in check helps ensure your Randell refrigerator operates reliably and efficiently in a demanding commercial kitchen environment.

Troubleshooting Common Randell Refrigerator Problems

Effective Randell refrigerator troubleshooting helps identify issues early and ensures optimal performance. Addressing common problems quickly can extend the lifespan of your refrigeration system.

Rnadell Refrigerator Not Cooling Properly

The refrigerator struggles to maintain the desired temperature, causing food to spoil and affecting overall kitchen operations.

Possible Causes:

-

Condenser coils are clogged with dirt, hindering effective heat exchange.

-

Faulty thermostat is failing to regulate the temperature.

-

Low refrigerant levels due to leaks.

-

Door seals allow cold air to escape.

-

Overloaded interior blocking airflow.

Symptoms:

-

Food is spoiling quickly.

-

Interior temperature is warmer than the set point.

How to Fix:

-

Clean Condenser Coils: Clean the condenser coils thoroughly to improve heat dissipation.

-

Check and Replace Thermostat: If the thermostat is not accurately controlling the temperature, test it and replace it.

-

Assess Refrigerant Levels: Have a specialist check for leaks and refuel the system as necessary.

-

Examine Door Seals: Replace damaged door gaskets to ensure a proper seal.

-

Avoid Overloading: Rearrange or reduce contents to allow proper airflow inside the refrigerator.

Compressor Runs Constantly

The compressor runs nonstop without turning Off”, which increases energy consumption and stresses the refrigeration system.

Possible Causes:

-

Dirty condenser coils are causing overheating.

-

Refrigerant leak lowers cooling capacity.

-

Thermostat is set too low or is malfunctioning.

-

Poor ventilation is restricting airflow.

Symptoms:

-

Compressor running nonstop.

-

Leads to higher energy use and increased utility costs.

How to Fix:

-

Clean Condenser Coils: To improve cooling effectiveness, clear the coils of dirt and debris.

-

Check for Refrigerant Leak: Repair leaks and recharge refrigerant through a qualified technician.

-

Adjust or Replace Thermostat: Correct thermostat settings or replace it if defective.

-

Improve Ventilation: Ensure adequate space around the unit for proper airflow.

Excessive Frost or Ice Buildup

Ice forms excessively inside the unit or on coils, limiting airflow and reducing the refrigerator’s cooling effectiveness.

Possible Causes:

-

Defrost timer or heater is malfunctioning.

-

Door left open or seal damaged.

-

Drain line clogged or frozen.

Symptoms:

-

Ice buildup on coils or inside the cabinet.

-

Door is difficult to close or open due to ice accumulation.

How to Fix:

-

Test Defrost System: Inspect and repair or replace faulty defrost components.

-

Check Door Seal and Usage: Ensure the door closes properly and replace worn seals.

-

Clear Drain Line: Unclog and clean the drain line to prevent ice formation.

Water Leaking Inside or Outside the Unit

Water collects inside or around the refrigerator, potentially damaging floors and creating hygiene issues in the kitchen.

Possible Causes:

-

Clogged or frozen drain line.

-

Refrigerator is not level.

-

Excess condensation from faulty door seals or humidity.

Symptoms:

-

Water pooling inside or around the unit.

-

Damp floor near the refrigerator.

How to Fix:

-

Unclog Drain Line: Clear any blockages to restore proper drainage.

-

Level the Refrigerator: Adjust the refrigerator legs or base to ensure it sits level.

-

Inspect Door Seals: Replace worn or damaged door gaskets to prevent condensation.

Unusual Noises (Buzzing, Clicking, or Rattling)

Unusual noises while running may indicate mechanical or electrical issues that could escalate if left unattended.

Possible Causes:

-

Loose or worn fan blades.

-

Compressor mounting issues.

-

Electrical component faults.

-

Items touching the fan or compressor.

Symptoms:

-

Loud or irregular noises during operation.

-

Vibrations were felt on the refrigerator's body.

How to Fix:

-

Examine and Secure Fan Blades: Clear any obstructions and tighten or replace fan blades.

-

Check Compressor Mounts: Secure the compressor mounts and inspect for damage.

-

Test Electrical Components: Repair or replace faulty wiring, relays, or other electrical parts.

-

Remove Obstructions: Ensure no items are contacting moving parts inside the unit.

Check out this guide on how to fix common Continental refrigerator issues to keep your commercial kitchen running smoothly and efficiently.

When to Replace Your Randell Refrigerator Instead of Repair

Knowing when to replace your Randell refrigerator can save you time, money, and prevent disruptions in your commercial kitchen. Consider replacement if you notice:

-

Frequent Breakdowns: The unit requires repairs more often than it functions properly, increasing downtime.

-

High Repair Costs: The cost of repairs is close to or greater than half of the price of a new refrigerator.

-

Old Age: The refrigerator is over 10-15 years old, and parts are becoming scarce or obsolete.

-

Inefficient Energy Use: The unit consumes significantly more electricity than newer models, raising operating costs.

-

Inconsistent Cooling: Persistent temperature fluctuations continue despite multiple repairs, risking food safety.

-

Excessive Noise: Noises indicate major mechanical wear that repairs can’t reliably fix.

-

Obsolete Technology: The refrigerator lacks modern features like improved insulation or better controls that increase efficiency.

-

Safety Concerns: Electrical or refrigerant system issues pose risks that repairs can’t adequately address.

When these signs appear, replacing your Randell refrigerator is often the smarter, more cost-effective choice for reliable kitchen operations.

Preventative Maintenance for Randell Refrigerators

Implementing a proactive maintenance plan can significantly prolong your equipment’s lifespan, lower repair expenses, and maintain efficiency and food safety.

Weekly Maintenance

-

Clean Shelves and Interior: To avoid odors and bacterial accumulation, thoroughly clean the shelves and interior using a gentle, food-safe cleaner.

-

Monitor Temperature: Check and log temperature readings daily to ensure compliance with safety standards and track performance.

Monthly Maintenance

-

Clean Condenser Coils: Use a vacuum or soft brush to remove dust and debris that can reduce cooling efficiency.

-

Inspect and Clean Door Gaskets: Look for wear or damage, and clean gaskets with warm water to maintain a tight seal and reduce energy loss.

Quarterly Maintenance

-

Check Evaporator Coils and Fans: Inspect for frost buildup or obstructions restricting airflow.

-

Ensure Proper Airflow: Reorganize contents inside the cabinet as needed to promote consistent cooling.

Annual Maintenance

-

Professional System Inspection: Have a licensed technician check refrigerant levels, compressor performance, and electrical connections for optimal operation.

-

Deep Cleaning Service: Schedule a professional deep cleaning of the refrigeration system to remove hidden dirt and contaminants.

Regular maintenance helps avoid expensive breakdowns, guarantees food safety, boosts efficiency, and supports compliance with regulations.

Check out this quick guide to learn how to clean commercial refrigerator condenser coils and ensure optimal cooling performance.

Conclusion

Proactively addressing common Randell refrigeration parts problems in commercial kitchens helps prevent disruptions and costly repairs. By quickly identifying symptoms and signs of issues, kitchen teams can implement effective troubleshooting steps to restore proper function and maintain optimal food storage conditions. Consistent care and attention to these challenges not only safeguard food quality but also extend the life of your Randell refrigerated prep table. Additionally, taking the time to troubleshoot and maintain your Randell undercounter refrigerator ensures your kitchen operates smoothly and efficiently every day.

FAQs

What is the most common refrigerator failure?

A malfunctioning compressor or thermostat is the most frequent failure. The refrigerator frequently stops cooling adequately because of these parts.

What is the first thing to check when the refrigerator stops working?

First, make sure the power outlet is operational and the refrigerator is plugged in. Make sure the circuit breaker hasn't tripped by checking it as well.

How do you reset a refrigerator that is not cooling?

The refrigerator must be reset by disconnecting it for about five minutes and then plugging it back in. This can occasionally fix small electrical issues and bring cooling back.

What is the problem when a refrigerator is not cooling?

Low refrigerant levels, a malfunctioning thermostat, and filthy condenser coils are common causes. Each can affect the refrigerator's ability to maintain the right temperature.