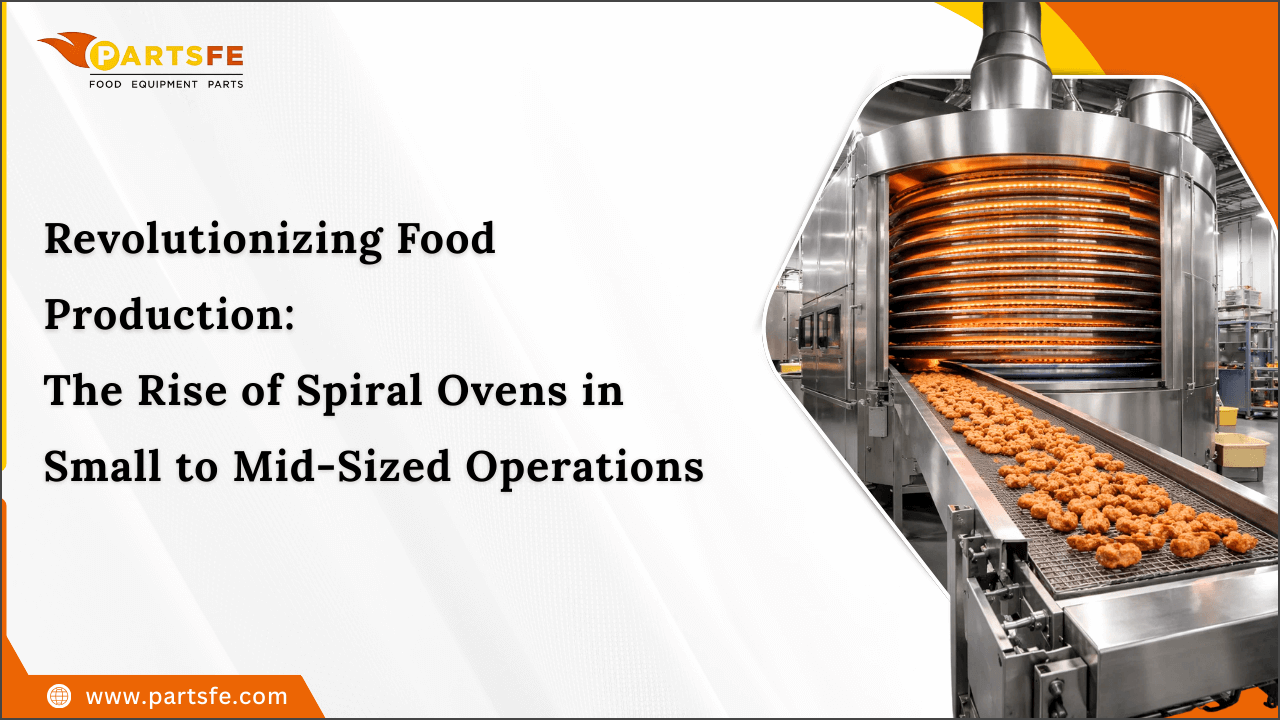

Revolutionizing Food Production: The Rise of Spiral Ovens in Small to Mid‑Sized Operations

The food production industry is evolving rapidly, and small to mid-sized operations are turning to innovative solutions to stay competitive. Among these, spiral ovens have emerged as a game-changer, offering consistent baking, faster throughput, and improved efficiency. Their compact design and advanced technology allow smaller businesses to scale production without sacrificing quality.

From artisanal bread to frozen meals, spiral ovens help streamline workflows, reduce labor demands, and maintain product consistency. By adopting this technology, small and mid-sized food producers can boost output, improve operational efficiency, and meet growing consumer demand with high-quality, reliable results.

Understanding Spiral Ovens: How They Work and Improve Food Production

Spiral ovens are vertical continuous conveyor ovens that cook food by moving it through a spiraled belt within a controlled chamber. Small to mid-sized operations benefit from this design because it allows food to cook evenly over an extended period without requiring a large footprint or constant manual handling. Temperature, airflow, and humidity are carefully regulated, allowing for the precise cooking of a wide range of products.

How Spiral Ovens Operate:

-

Spiral Belt Movement: Food travels upward or downward along a helical conveyor, allowing long cook times in a compact vertical space.

-

Layered Cooking Tiers: Multiple stacked belts create separate levels, so food on each tier receives consistent heat while maximizing throughput.

-

360° Airflow Circulation: Fans push heated air evenly around the products, ensuring uniform cooking and preventing hot or cold spots

-

Adjustable Parameters: Operators control temperature, belt speed, airflow, and humidity independently to suit different recipes and product sizes.

-

Zoned Chamber Operation: Some ovens have separate heating zones along the spiral, allowing different parts of the product to be baked at precise temperatures or humidity levels.

-

Continuous Processing: The spiral conveyor ensures a nonstop flow of food, reducing downtime, streamlining workflow, and allowing integration with upstream prep and downstream packaging systems.

How Spiral Ovens Perform in Small and Mid-Sized Food Production with Tiered Belts and Cooking Process

Spiral ovens are vital for small and mid-sized food production, offering efficiency, consistency, and space-saving design. They help local bakeries and regional manufacturers produce high-quality products in larger batches than a regular kitchen.

How Tiered Belts Drive Efficient Spiral Oven Operation:

-

Dynamic Tiered Belts for Small and Mid-Sized Producers: Multiple belts stacked vertically allow local bakeries to bake hundreds of pastries daily and regional facilities to handle thousands of bread rolls efficiently without expanding floor space.

-

Targeted Precision Airflow: Precision airflow ensures that delicate products like croissants rise evenly in small bakeries, while denser items such as buns and frozen foods in mid-sized operations cook thoroughly without burning.

-

Thermal Retention Layers: The spiral design traps heat between tiers, letting smaller producers achieve industrial-level consistency in crust, color, and texture without high energy costs.

-

Moisture Preservation System: Controlled humidity in each loop prevents drying, keeping artisanal breads soft and frozen products moist—critical for small shops and regional suppliers alike.

-

Adaptive Loading Techniques: Items can be staggered across belts, optimizing airflow exposure for mixed batches, whether in a local pastry shop or a mid-sized frozen food facility.

-

Process Synchronization: Tiered belts enable simultaneous cooking of multiple products, minimizing bottlenecks and maintaining steady output for small and mid-sized operations.

Note: Spiral ovens with tiered belts typically run at 220–240 V and 160–220 °C (320–428 °F). Ensure trays are loaded properly and avoid direct contact with hot surfaces to prevent burns.

Benefits of Using Spiral Ovens in Small and Mid-Sized Food Production

Spiral ovens help small and mid-sized food producers streamline operations and meet growing demand with confidence. Their space-saving design and consistent performance make them a practical solution for improving productivity while maintaining high product standards.

How Different Food Producers Benefit from Spiral Ovens:

|

Food Producers |

Products |

Spiral Oven Benefits |

|

Local Bakeries |

Sourdough bread, bagels, muffins |

Consistent baking, high throughput in limited space, uniform browning, reduced labor costs |

|

Artisanal Dessert Shops |

Cheesecakes, cupcakes, cookies |

Precise temperature and airflow for delicate treats, preserves moisture and texture for high-end customers |

|

Frozen Food Producers |

Frozen dinners, frozen pizza, frozen bread |

Even cooking, moisture retention, scalable production for regional distribution |

|

Small Pizza & Sandwich Manufacturers |

Personal pizzas, calzones, stuffed breads |

Tiered belts allow multiple products at once, faster cooking, consistent quality for takeout and delivery |

|

Regional Snack Companies |

Pretzels, kettle chips, granola bars |

High-volume output, continuous production, energy-efficient for mid-sized snack businesses supplying local retailers |

|

Meal Prep & Ready-to-Eat Services |

Healthy bowls, roasted proteins |

Continuous conveyor ensures fast, precise cooking, ideal for subscription meal services and local delivery operations |

|

Specialty Health Food Producers |

Gluten-free bread, vegan pastries |

Controlled humidity and temperature maintain product integrity, critical for niche health markets |

|

Confectioneries and |

Brownies, macarons, baked candies |

Gentle airflow and tiered belts prevent damage, ensuring consistent high-quality products for boutique shops |

Best Practices for Consistent and Safe Baking:

-

Standardize Recipes: Track and maintain consistent bake times, temperatures, and conveyor settings to ensure uniform quality across all shifts.

-

Maintain Daily Cleanliness: Remove crumbs, spills, and grease from ovens and surrounding areas to uphold hygiene standards and reduce fire risk.

-

Calibrate Sensors Regularly: Periodically verify temperature probes and airflow sensors to maintain precise control over baking conditions.

-

Balance Load Distribution: Avoid overcrowding trays to ensure even airflow and consistent cooking across all products.

Find out how much it costs to replace an oven temperature sensor, including parts, labor, and factors that can affect total service expenses.

Core Components of Spiral Ovens Enabling Smart Controls and Workflow Integration

Spiral ovens combine mechanical precision with digital automation to deliver consistent cooking and seamless workflow integration. Understanding their core components shows how each part contributes to efficiency, quality, and automation in small and mid-sized food production.

Product Flow and Space Optimization:

-

Spiral Conveyor Belt: A helical belt that continuously moves food through the oven for uniform cooking and high-volume output.

-

Cooking Tiers / Layers: Vertically stacked belt levels that maximize space while allowing multiple products to cook simultaneously.

-

Loading and Unloading Stations: Entry and exit points that connect the oven smoothly to preparation and packaging lines.

Heating and Air Circulation System:

-

Heating Elements / Burners: Gas, electric, or steam systems that generate controlled and consistent heat inside the oven chamber.

-

Airflow Fans / Blowers: Circulate heated air evenly throughout the spiral to eliminate hot and cold spots.

-

Air Ducts / Channels: Direct airflow precisely across tiers to maintain uniform temperature and moisture balance.

Temperature and Moisture Control:

-

Temperature Sensors / Thermocouples: Continuously monitor internal heat levels to maintain accurate and stable cooking conditions.

-

Humidity Control System / Steam Injectors: Regulate moisture levels to preserve texture and prevent product drying.

-

Multi-Zone Control System: Enables different temperature and humidity settings in separate sections of the spiral.

Automation and Smart Control Systems

-

Digital Control Interface / Touchscreen Panel: Allows operators to program recipes and adjust belt speed, temperature, humidity, and airflow.

-

Automation and Monitoring Systems: Track performance in real time and integrate the oven with upstream and downstream equipment.

Safety Tip: Always ensure doors and access panels are fully closed and properly sealed before starting the oven to prevent heat loss, maintain internal pressure, and protect staff from burns or heat exposure. Regularly inspect seals and hinges to ensure safe operation during production.

Genuine oven parts ensure consistent, high-quality baking and work together to deliver efficient automated cooking, making spiral ovens essential for small and mid-sized food production.

Summary: The Future of Efficient and Scalable Food Production with Spiral Oven Technology

Spiral ovens do more than just bake efficiently; their design enables small and mid-sized producers experiment with complex product combinations while maintaining consistent output. Their tiered design, precision airflow, and real-time monitoring allow operators to achieve results usually reserved for industrial bakeries. With the right setup, these ovens reduce waste, improve workflow synchronization, and unlock production flexibility previously unattainable for smaller operations.

Key Takeaways

-

Spiral ovens allow simultaneous baking of multiple product types without flavor or texture compromise.

-

Tiered belts enable strategic staggering of items for optimal airflow and moisture control.

-

Real-time temperature and humidity feedback minimizes overcooking and reduces product loss.

-

Flexible belt speed and zone control support both artisanal and frozen food production in the same oven.

-

Energy is conserved by heat retention between tiers, lowering operational costs for smaller producers.

-

Adaptive loading and unloading systems reduce bottlenecks and improve batch-to-batch consistency.

-

Integration with digital monitoring helps track production metrics and uncover efficiency improvements.

Tired of wasting money on low-quality replacement parts that fail quickly? Explore high-quality kitchen equipment spare parts supplier for commercial restaurants at the best prices. We carry essential components for ovens, fryers, dishwashers, grills, and more like lids, hinges, handles, and drain plugs from top brands such as True, Southbend, Garland, and Vulcan. Fast shipping is available to your doorstep!

References:

https://engx.theiet.org/f/wiring-and-regulations/22013/restaurant-kitchen-3-phase-oven-rcds

https://www.epa.gov/sites/default/files/2020-10/documents/rel_c09s0906.pdf

https://dl.icdst.org/pdfs/files/18bda7d749c0be429bf3592300e2b647.pdf

FAQs

Why are spiral ovens more expensive than deck or convection ovens?

They offer continuous cooking, multi-tier conveyors, uniform airflow, and automated controls, which standard ovens cannot provide.

How much does a spiral oven cost?

Compact spiral ovens for small bakeries usually range from $25,000 to $40,000, including basic installation and shipping.

How do spiral ovens save labor and energy in kitchens?

Automation reduces manual monitoring, saving 1–3 full-time operators, while recirculated airflow and optimized cooking cycles cut energy use by 20–40% per product.

How long do spiral ovens generally last?

With proper maintenance, high-quality spiral ovens can last 10–15+ years, offering reliable long-term performance.

|

Disclaimer: This content is for educational purposes only and should be used as a reference. Equipment performance, operation, and servicing may vary by model. Always observe manufacturer instructions and proper safety measures. |