11 Commercial Dishwasher Maintenance Tips to Prevent Costly Breakdowns

In a fast-paced commercial kitchen, a dishwasher is more than just a convenience; it’s a critical piece of equipment that keeps operations running smoothly and hygiene standards intact. When a commercial dishwasher breaks down unexpectedly, the result is lost time, rising repair bills, and serious disruptions to service. That’s why commercial dishwasher maintenance is not optional—it’s a necessity.

This article covers proven commercial dishwasher maintenance tips designed to help restaurants, hotels, cafeterias, and foodservice operators prevent breakdowns, reduce repair costs, and extend the life of their equipment. Whether you manage one unit or an entire commercial kitchen, proactive care can save you thousands in long-term expenses.

Why Regular Commercial Dishwasher Maintenance Prevents Breakdowns

Many equipment failures don’t happen overnight; they build slowly due to neglected cleaning, scale buildup, worn parts, or improper operation. Without routine care, even a high-end unit can suffer frequent downtime.

Preventive Maintenance vs Emergency Repairs

Emergency service calls for commercial dishwasher repair are often expensive and disruptive. In contrast, preventive maintenance focuses on identifying small issues before they escalate into major failures. Simple actions like cleaning filters or checking water temperature can prevent pump damage, heater failure, or electrical faults.

Lower Operating Costs and Better Efficiency

A poorly maintained dishwasher uses more water, more energy, and more chemicals to achieve the same results. Over time, this inefficiency increases utility bills and puts unnecessary strain on internal components. Consistent preventive maintenance for dishwashers helps the unit run efficiently while keeping operating costs predictable.

Compliance and Food Safety

Health inspections often fail kitchens due to poor sanitation caused by malfunctioning dishwashers. Routine maintenance ensures proper wash temperatures, effective rinsing, and hygienic results—protecting both your business reputation and compliance status.

Looking for reliable parts for restaurant equipments? PartsFe is your one-stop destination for commercial kitchen equipment parts, offering hoses, racks, spray arms, and more from trusted brands like Hobart, Jackson, Champion, and CMA at competitive prices.

11 Essential Commercial Dishwasher Maintenance Tips to Avoid Costly Repairs

These 11 commercial dishwasher maintenance tips form a practical, easy-to-follow system that prevents unexpected breakdowns and extends equipment lifespan.

1. Clean Scrap Trays and Filters Daily

Food debris trapped in scrap trays and filters restricts water flow and strains pumps. Daily cleaning is one of the most effective commercial dishwasher cleaning tips to prevent clogs and circulation issues.

2. Rinse Dishes Before Loading

Pre-rinsing dishes reduces food buildup inside the unit, minimizing blockages in spray arms and drain lines. This simple habit significantly lowers long-term maintenance needs.

3. Inspect and Clean Wash Arms Regularly

Blocked or damaged spray nozzles cause uneven washing and poor results. Remove and clean wash arms weekly to ensure consistent water pressure and coverage.

4. Delime the Dishwasher to Control Scale Buildup

Hard water leads to mineral deposits on heating elements, sensors, and internal surfaces. Regular deliming prevents overheating, slow cycles, and premature component failure, especially in high-use kitchens.

5. Check Detergent and Rinse Aid Levels

Incorrect chemical levels affect wash performance and may damage internal parts. Always use manufacturer-approved products and adjust dosing based on water hardness.

6. Monitor Water Temperature and Pressure

Low water temperature leads to poor sanitation, while excessive pressure can damage valves and hoses. Maintaining proper specifications is a core part of commercial dishwasher maintenance best practices.

7. Inspect Door Gaskets and Seals

Cracked or worn gaskets cause leaks, heat loss, and longer cycle times. Replacing these low-cost components early prevents water damage and energy waste.

8. Clean the Interior Tank and Walls Weekly

Grease, detergent residue, and mineral buildup reduce efficiency. Weekly interior cleaning keeps sensors accurate and prevents corrosion.

9. Tighten Hoses and Check for Leaks

Loose connections or aging hoses often cause sudden failures. Regular inspections help identify small leaks before they lead to flooding or electrical damage.

10. Replace Worn Commercial Dishwasher Parts Promptly

Ignoring worn components often leads to more expensive repairs later. Replacing seals, pumps, heating elements, or filters early reduces downtime and repair costs.

11. Schedule Professional Preventive Maintenance Checks

Annual or semi-annual professional inspections help detect electrical, mechanical, and control issues early. This step alone can drastically reduce the need for emergency dishwasher troubleshooting guide scenarios

Explore commercial dishwasher 101: types, costs, installation & maintenance guide to choose the right system and keep it running efficiently.

Common Warning Signs Your Commercial Dishwasher Needs Immediate Attention

Even with regular care, issues can still arise. Recognizing early warning signs allows you to act before complete failure occurs.

|

Warning Sign |

What It Indicates |

Why Immediate Attention Matters |

|

Poor Cleaning or Drying Results |

Clogged spray arms, low rinse temperature, or chemical imbalance |

Leads to unhygienic dishes, failed health inspections, and repeat wash cycles |

|

Unusual Noises or Vibrations |

Pump issues, loose components, or foreign objects trapped inside |

Ignoring noises can result in major mechanical failure and costly repairs |

|

Water Leaks or Error Codes |

Worn gaskets, damaged hoses, cracked fittings, or sensor/heating element issues |

Leaks can damage surrounding equipment; error codes signal critical system faults |

|

Longer Cycle Times |

Scale buildup or failing heating components |

Increases energy usage and indicates early-stage component failure |

|

Low Water Pressure During Wash |

Failing wash pump, clogged filters, or inlet valve problems |

Results in poor cleaning performance and added strain on internal components |

|

Inconsistent Water Temperature |

Malfunctioning thermostat, heating element, or control board |

Prevents proper sanitization and can violate food safety regulations |

|

Dishwasher Fails to Drain Completely |

Blocked drain hose, faulty drain pump, or debris buildup |

Standing water promotes bacterial growth and accelerates internal corrosion |

|

Machine Fails to Start or Stops Mid-Cycle |

Electrical issues, door switch failure, or control board malfunction |

Causes operational downtime and often signals a critical component failure |

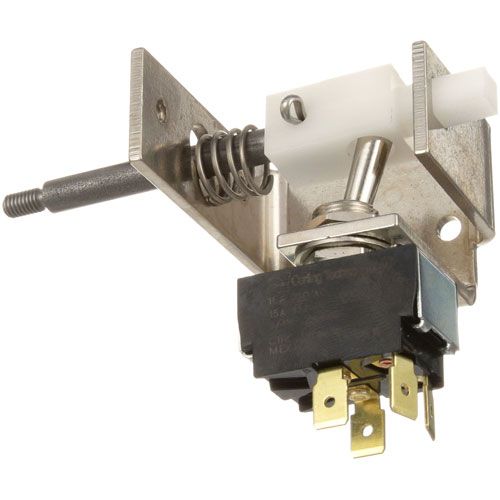

Check out how to replace mounting brackets on a commercial dishwasher for a quick, step-by-step guide to secure installation and reliable performance.

How Preventive Maintenance Extends Dishwasher Lifespan and Efficiency

Routine care doesn’t just prevent failures. It actively improves performance and return on investment.

Reduced Stress on Critical Components

Regular cleaning of filters, spray arms, and internal surfaces allows water to circulate freely, reducing strain on pumps, motors, and heating elements. Proper water flow and correct operating temperatures prevent components from overworking, which helps extend the lifespan of expensive internal parts.

Lower Utility Bills

A well-maintained dishwasher heats water faster and completes cycles more efficiently. Scale-free heating elements, balanced detergent levels, and unobstructed spray arms reduce energy, water, and chemical consumption. Over time, this efficiency translates into noticeable savings on monthly utility costs.

Fewer Emergency Repairs

Following a structured dishwasher maintenance checklist helps catch small issues early—such as loose hoses, worn gaskets, or minor leaks—before they escalate into major failures. This proactive approach reduces emergency repair calls and prevents costly downtime during busy service periods.

Improved Workflow in Commercial Kitchens

Reliable dishwashers ensure faster turnaround of clean dishes, keeping kitchen operations smooth and uninterrupted. Consistent performance supports better coordination between prep, cooking, and service teams, improving overall productivity.

Better Cleaning and Sanitation Results

Preventive maintenance ensures proper wash temperatures and spray coverage, leading to consistently clean and sanitized dishware. This helps maintain hygiene standards and pass health inspections with confidence.

Extended Equipment Lifespan

By reducing wear, improving efficiency, and preventing sudden failures, preventive maintenance significantly increases the usable life of a commercial dishwasher, delaying costly replacements and maximizing your equipment investment.

Conclusion: Proactive Commercial Dishwasher Maintenance Saves Money

Proactive commercial dishwasher maintenance is not just a best practice; it’s a smart financial decision for any foodservice operation. Ignoring routine care often leads to unexpected breakdowns, emergency service calls, and premature equipment replacement, all of which can quickly strain operational budgets. In contrast, following proven commercial dishwasher maintenance tips helps ensure reliable performance, energy efficiency, and ongoing compliance with hygiene standards.

By applying the 11 essential maintenance tips outlined in this guide, monitoring early warning signs, and replacing worn On time, operators can significantly reduce downtime and avoid costly repairs. Preventive maintenance protects your investment, supports smooth kitchen operations, and delivers long-term value.

Key Takeaways at a Glance:

-

Regular maintenance prevents costly breakdowns and emergency repairs

-

Clean components reduce strain on pumps, heaters, and motors

-

Efficient operation lowers water, energy, and chemical costs

-

Early part replacement extends overall equipment lifespan

-

Consistent care ensures uninterrupted, hygienic kitchen operations

In the long run, consistent maintenance is always more cost-effective than repair. A disciplined, proactive approach today ensures your commercial dishwasher continues to perform efficiently and reliably for years to come.

FAQs

What are the commonly encountered maintenance problems in commercial kitchens?

Common issues include clogged filters, scale buildup, worn seals, leaking hoses, inconsistent water temperature, electrical faults, and neglected preventive maintenance causing frequent equipment breakdowns.

What should be done with a commercial dishwasher at the end of each work day?

At day’s end, drain the unit, clean filters and scrap trays, wipe interior surfaces, inspect spray arms, and leave the door open to air-dry and prevent odors.

How often should you salt a commercial dishwasher?

Salt should be refilled when the indicator light appears, typically every two to four weeks, depending on water hardness, usage frequency, and manufacturer recommendations.