How to Troubleshoot Hamilton Beach Commercial Mixers in High-Volume Foodservice Operations

Hamilton Beach commercial mixers are essential in high-volume foodservice operations, from busy restaurants and bakeries to catering kitchens and institutional dining facilities. Designed for heavy workloads, consistent mixing, and large batch preparation, these mixers keep kitchens efficient and productive. Even the most reliable models can develop issues over time due to use, improper handling, or lack of maintenance. For foodservice operators, knowing how to troubleshoot and maintain these mixers is vital to prevent downtime, ensure food quality, and maintain smooth operations.

In fast-paced kitchens, a broken mixer can disrupt workflows and delay meal preparation. This guide offers step-by-step methods to identify problems, apply practical fixes, and perform preventive maintenance, ensuring your Hamilton Beach mixer parts operates reliably under high-volume, high-stress conditions.

How Hamilton Beach Commercial Mixers Function in High-Output Foodservice Operations

Hamilton Beach commercial mixers are essential in high-output foodservice operations, delivering reliable performance, consistent results, and durability under continuous use. These mixers help busy kitchens handle large volumes efficiently while maintaining product quality.

-

High-Performance Motors: Built to endure heavy-duty use, the motor provides the power necessary to drive mixing attachments through dense ingredients.

-

Planetary Mixing Mechanism: The attachment rotates on its axis while moving around the bowl, ensuring thorough incorporation of all ingredients.

-

Gearbox and Drive System: Transmits motor power to attachments, maintaining consistent speed and torque even under high-volume workloads.

-

Bowl and Attachment System: Accommodates a variety of mixing tasks with standardized attachments like dough hooks, whisks, and paddles, enabling versatility for large-scale recipes.

-

Control Panel: Offers speed adjustment, start/stop functionality, and safety features such as bowl-lift interlocks to protect operators during fast-paced operations.

-

Durability for Continuous Use: Heavy-duty construction and stainless-steel bowls withstand nonstop mixing in restaurants, bakeries, catering services, and institutional kitchens.

-

Efficiency and Consistency: Uniform mixing ensures every batch meets quality standards, reduces waste, and maximizes productivity in high-output foodservice operations.

Understanding these components allows operators to fully leverage Hamilton Beach mixers for reliable, high-volume performance.

Looking to keep your commercial mixer running smoothly in high-volume kitchens? PartsFe offers essential replacement parts like motors, gearboxes, bowl lifts, mixing attachments, and more. Whether you need Hamilton Beach mixer parts or hobart mixer parts, maintain peak performance and prevent downtime with high-quality components from PartsFe.

Step-by-Step Troubleshooting for Hamilton Beach Commercial Mixer Issues

A structured troubleshooting approach helps identify problems efficiently while preventing further damage. Follow these steps to keep your high-volume kitchen running smoothly:

Following these steps helps maintain reliable performance, prevent downtime, and extend the life of your Hamilton Beach commercial mixer in high-volume kitchens.

Fixes and Adjustments for High-Stress Hamilton Beach Mixing Applications

Hamilton Beach hand mixers and stand mixers are essential in high-volume kitchens. Knowing how to address latch issues, motor strain, and heat ensures smooth, reliable operation under heavy use.

-

Latch Issues (Models 63391 & 63392): Check the latch mechanism if the bowl or attachments fail to lock properly. Clean debris around the latch, lightly lubricate moving parts, and ensure the latch engages fully before operation to prevent misalignment.

-

Lubrication and Gear Maintenance: Regularly lubricate gears, shafts, and moving parts as recommended in the user manual. Inspect gearboxes for wear or damage, replacing components if necessary to maintain smooth operation.

-

Correct Attachment Use: Use the correct attachment for each task; for example, avoid using a whisk for heavy dough. Replace worn or bent attachments to prevent uneven mixing and motor strain.

-

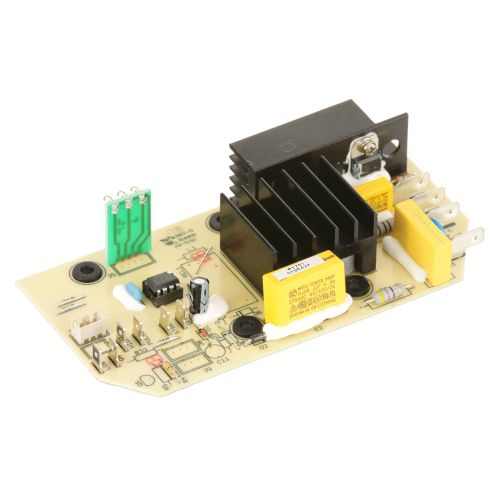

Motor and Electrical Repairs: Clean vents and cooling fans to prevent overheating. Replace faulty motor brushes if the motor runs inconsistently or produces sparks. Check wiring connections and repair loose or corroded terminals.

-

Bowl Lift and Safety Mechanism Adjustments: Tighten or lubricate bowl lift gears and levers if the bowl does not move smoothly. Verify interlock switches are functioning, as a safety interlock failure can prevent the mixer from operating.

-

Speed and Overload Management: Avoid overloading the mixer; follow recommended batch sizes for different attachments. Gradually increase speeds to prevent motor strain and ensure consistent mixing results.

Following these fixes, Hamilton Beach mixers run reliably under high-volume conditions, reducing downtime and ensuring consistent results.

Check out Hobart mixer troubleshooting: here's how to fix common problems to quickly resolve issues and keep your kitchen running smoothly.

When to Repair or Replace Hamilton Beach Commercial Mixer Components

Hamilton Beach commercial mixers are built for high-volume kitchens, but parts can wear over time. Knowing when to repair or replace components ensures consistent performance and prevents downtime.

|

Component |

Signs of Wear or Damage |

Repair or Replace? |

Note / Tips |

|

Motor |

Inconsistent speed, overheating, strange noises |

Replace if electrical faults or severe wear; minor issues may be repaired |

Regularly clean vents and fans; avoid overloading |

|

Gears / Gearbox |

Grinding, slipping, uneven mixing |

Replace worn gears; lubricate regularly |

Use only manufacturer-recommended lubricants |

|

Bowl Lift Mechanism |

Bowl does not raise/lower smoothly, loose gears |

Repair or replace worn parts |

Check safety interlocks after adjustments |

|

Attachments (Hooks, Whisks, Paddles) |

Bent, broken, or worn |

Replace |

Always use the correct attachment for the task |

|

Control Panel / Switches |

Non-responsive buttons, erratic speeds |

Repair minor electrical issues; replace if damaged |

Check for corrosion or loose wiring |

|

Power Cord / Wiring |

Frayed cords, exposed wires, intermittent power |

Replace immediately |

Ensure the outlet meets the mixer’s power requirements |

|

Bowl / Housing |

Cracks, dents, deformation |

Replace |

Prevent contamination and ensure proper attachment fit |

Explore Kitchenaid mixer components 101: a beginner’s guide to understanding each part and maintaining your mixer for optimal performance.

Preventive Maintenance Strategies to Avoid Hamilton Beach Mixer Failures

Preventive maintenance is critical in high-volume kitchens, where mixer downtime can disrupt operations and slow food preparation. Implementing regular care routines ensures consistent performance and extends the life of your equipment.

Routine Cleaning

-

Wash bowls, attachments, and external surfaces daily to remove food residue.

-

Use mild detergents and warm water; avoid harsh chemicals that can damage metal or coatings.

-

Pay attention to hard-to-reach areas, including the bowl lift and attachment hub, where buildup can affect operation.

Regular Lubrication

-

Apply food-grade lubricant to gears, shafts, and moving parts on a set schedule.

-

Follow manufacturer-recommended intervals to prevent excessive wear and overheating.

-

Check the planetary mixing mechanism and gearbox for smooth rotation during lubrication.

Inspection and Testing

-

Perform weekly inspections of attachments, belts, and electrical components.

-

Test the mixer at low speeds before full operation to catch early signs of strain or unusual noise.

-

Look for bent or worn attachments that could affect mixing efficiency.

Environmental and Usage Checks (new point)

-

Ensure mixers are operated in clean, dry areas to prevent moisture-related corrosion.

-

Avoid overloading bowls beyond the recommended capacity to protect the motor and gears.

Scheduled Professional Servicing

-

Arrange periodic maintenance with certified technicians to assess motor health, gearbox integrity, and electrical safety.

-

Replace worn parts proactively to prevent unexpected breakdowns and costly repairs.

Following these strategies, operators can maximize mixer performance, cut repair costs, and ensure consistent food quality.

Conclusion: Maximize Efficiency with Hamilton Beach Mixers

Maintaining Hamilton Beach commercial mixers in busy kitchens requires proactive care, strategic maintenance, and timely part replacements. Proper attention to performance, load management, and component health keeps your mixers operating efficiently and reduces unexpected downtime, ensuring smooth high-volume food preparation.

Key Takeaways:

-

Clean all mixer surfaces, attachments, and hard-to-reach areas daily to prevent residue buildup and corrosion.

-

Apply food-safe lubricants to gears, shafts, and moving parts on a regular schedule to prevent friction-related wear.

-

Inspect planetary mechanisms, bowl lifts, and attachment hubs weekly for early signs of misalignment or damage.

-

Address latch malfunctions (models 63391 & 63392) and motor strain promptly to maintain consistent mixing performance.

-

Avoid exceeding recommended batch sizes and use correct attachments for specific recipes to protect the motor and gearbox.

-

Partner with certified service providers or use high-quality parts for restaurant equipment to ensure long-term reliability.

Proactive maintenance, careful operation, and quality replacement parts keep Hamilton Beach mixers running smoothly in high-stress, high-volume kitchens. This approach minimizes downtime, preserves food quality, and enhances overall kitchen efficiency.

FAQs

Where is the reset button on a Hamilton Beach iron?

The reset button is usually located on the base or near the power cord. Press it if the iron stops heating due to an automatic safety shutoff.

Why won't my Hamilton Beach hand mixer turn on?

Check that the mixer is properly plugged in and the outlet is working. Inspect the power cord and switches for damage or loose connections.

Why did my Hamilton Beach blender stop working?

The blender may have overheated or tripped a built-in safety feature. Allow it to cool, check for blockages, and ensure the jar is seated correctly.

Are Hamilton Beach mixers good?

Yes, Hamilton Beach mixers are reliable for high-volume and home kitchens. They offer durable construction, versatile attachments, and consistent mixing performance for a variety of recipes.

Does Hamilton Beach have a paddle attachment for stand mixers?

Yes, Hamilton Beach stand mixers come with a paddle attachment suitable for tasks like mixing batters, cookie dough, and other medium-consistency ingredients.