How to Maintain a Schaerer Coffee Machine A Complete Professional Guide

Schaerer coffee machine in a commercial kitchen is a high-performance tool that demands proper maintenance to ensure efficiency and consistent coffee quality. With heavy daily use, neglecting care can lead to breakdowns, costly repairs, and inconsistent drinks, affecting both workflow and customer satisfaction.

This professional guide provides step‑by‑step instructions for cleaning, servicing, and troubleshooting your Schaerer coffee machine parts for consistent coffee brewing every time in a busy commercial kitchen. By following these best practices, professional staff can keep the machine operating smoothly, extend its lifespan, and maintain consistent beverage quality throughout every service shift.

Troubleshooting Frequent Schaerer Coffee Machine Problems

Schaerer coffee machine troubleshooting is essential for keeping your machines running smoothly. Even reliable machines can encounter hiccups, and understanding potential issues and their solutions ensures professional-quality beverages consistently.

|

Problem |

Signs |

Cause |

Solution |

|

Weak or Overly Bitter Coffee |

Coffee tastes too weak or bitter |

Coffee grounds too fine or coarse, clogged filters, mineral buildup |

Adjust grinder, clean or replace filters, descale, and use filtered water |

|

Coffee Fails to Brew |

Machine does not dispense coffee |

Blocked brew unit or grinder, low water pressure, sensor malfunction |

Clean brew unit and grinder, check water supply, consult technician if needed |

|

Machine Doesn’t Power On |

Machine shows no power |

Power interruptions, electrical faults, blown fuses |

Check plug, outlet, and circuit breaker; contact service if unresolved |

|

Milk Frother Problems |

Milk does not froth properly |

Milk residue, worn components, and wrong temperature |

Clean milk system, inspect nozzles, recalibrate temperature, service if needed |

|

Leaks in Water or Coffee System |

Water or coffee leaks |

Worn seals, loose parts, overfilled containers |

Replace seals, secure parts, inspect regularly |

|

Grinder Malfunctions |

Beans are stuck or grinding inconsistently |

Jammed beans, residue buildup |

Clear hopper, clean grinder, adjust settings |

|

Error Codes or Alerts |

Error messages appear |

Sensor detecting irregularities |

Check the manual for code, reset or clean, call technician if persistent |

Safety Reminder: Always unplug your Schaerer coffee machine before cleaning, servicing, or handling internal components to avoid electric shock. Allow hot parts like the brew unit and steam wand to cool before touching, and handle all components carefully to prevent damage or injury

Looking for professional-grade coffee machine maintenance supplies? Shop high-quality Coffee machine replacement parts and accessories from PartsFe. We offer cleaning tablets, water filters, milk system cleaners, steam wand brushes, descaling agents, lubricants, brew unit lubricants, and fast shipping available to keep your machine reliable, hygienic, and brewing perfectly.

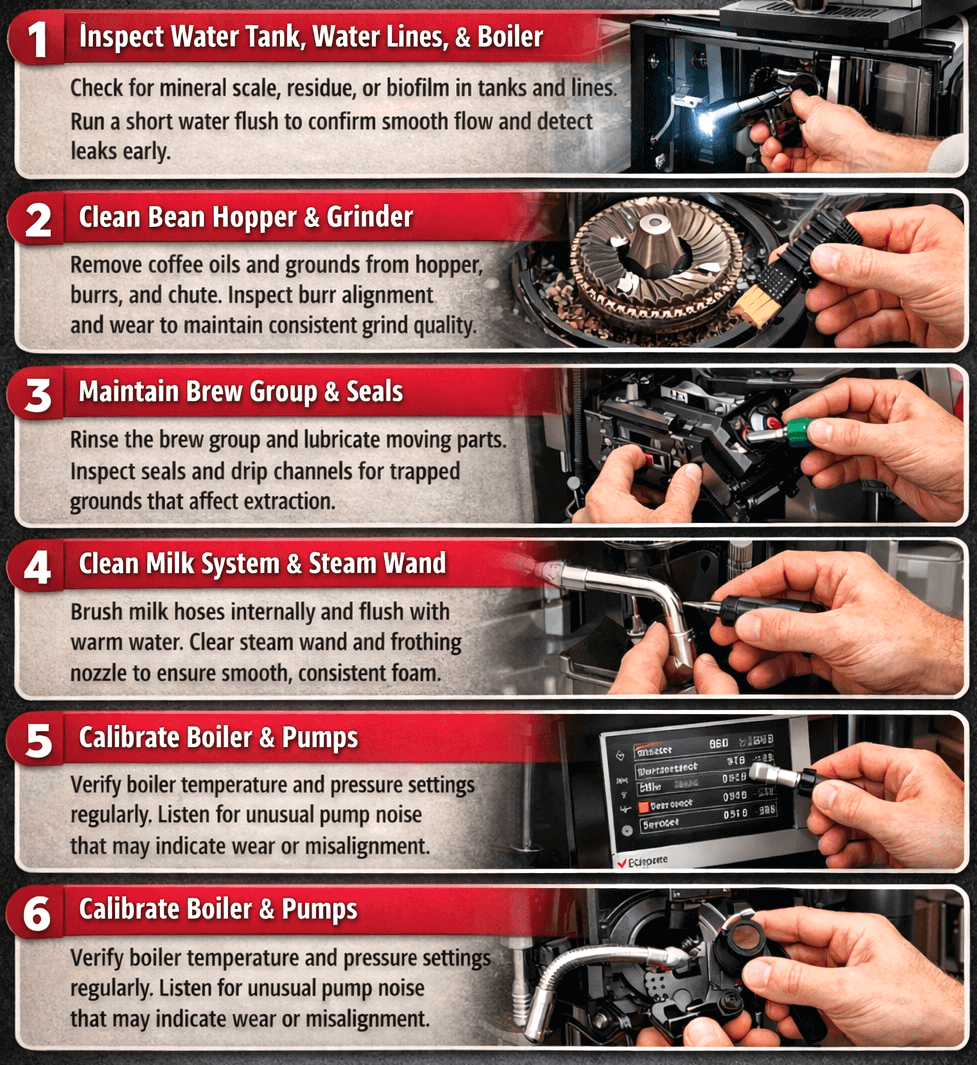

Step-by-Step Maintenance Process for Schaerer Coffee Machines

Maintaining your Schaerer coffee machine requires attention to hidden components and subtle checks to ensure consistent coffee quality. Follow these six essential steps to keep your machine in top condition

| Disclaimer: Schaerer coffee machines have complex hydraulic, electrical, and sensor systems. Improper maintenance or neglect can cause internal damage, reduce performance, or void the warranty. Always follow manufacturer guidelines and consult a certified technician for repairs or complex servicing. |

Common Mistakes That Shorten the Lifespan of Schaerer Coffee Machines

Even with regular care, small errors can quickly reduce the efficiency and durability of your Schaerer coffee machine. Avoid these common missteps:

-

Neglecting Milk and Brew Unit Cleaning: Residue from coffee oils and milk can clog internal components and sensors. Regular cleaning prevents blockages and maintains flavor quality.

-

Ignoring Water Quality: Using untreated or hard water accelerates scale buildup in boilers and pipes. Always use filtered or softened water to protect pumps, heaters, and internal tubing.

-

Skipping Software and Firmware Updates: Outdated software can reduce brewing efficiency and trigger errors. Keep your machine updated for optimal performance.

-

Incorrect Grinding and Brewing Settings: Using overly fine grinds or improper temperatures can strain the brew unit and affect coffee taste. Follow manufacturer-recommended settings.

-

Attempting DIY Repairs: Trying to repair pumps, boilers, or electronics without proper training can void warranties and cause permanent damage. Always consult a professional.

-

Overlooking Drip Tray and Waste Bin Cleaning: Ignoring daily disposal of coffee grounds or drip tray liquids can lead to unpleasant odors, mold growth, and mechanical issues.

-

Failing to Replace Water Filters on Time: Expired or clogged water filters reduce water flow, affect taste, and increase scale buildup. Replace filters according to the schedule.

-

Neglecting Lubrication of Moving Parts: Brew units and grinders need periodic lubrication. Skipping this can lead to wear, friction damage, and noisy operation.

Explore the commercial coffee maker parts guide to discover everything you need to know for maintenance, repairs, and replacements.

When to Call a Professional for Schaerer Coffee Machine Servicing

Some issues with Schaerer machines are subtle and easy to miss, but can severely impact performance if ignored. Professional help ensures these hidden problems are detected before they cause serious damage.

-

Irregular Coffee Flow Patterns: If espresso or milk textures fluctuate unpredictably despite correct settings, it may indicate partial blockages or sensor misalignment inside the brew unit.

-

Slow Heating or Extended Preheat Times: Boilers taking longer than usual to reach optimal temperature often signal early-scale formation or small pressure issues requiring a technician.

-

Unstable Milk Frothing Pressure: Inconsistent foam or sudden drops in steam pressure can indicate leaks or worn valves that are not visible during routine cleaning.

-

Subtle Grinder Vibrations or Humming: Slightly off-balance grinders or unusual humming may precede burr wear or motor strain and need professional calibration.

-

Water Tank or Pump Inconsistencies: Fluctuating water flow, even with clean filters, can indicate hidden airlocks, pump wear, or pressure sensor errors.

-

Frequent Auto-Clean Interruptions: If automatic cleaning cycles stop mid-process, it may reflect internal pump or dosing issues requiring specialized attention.

-

Hidden Electrical or Sensor Drift: Sensors losing calibration may trigger error codes or misread water levels, detectable only with the Schaerer coffee machine manual.

Addressing these subtle warning signs with certified technicians ensures your Schaerer machine stays efficient, reliable, and capable of producing perfect coffee every day.

Summary: Building a Long-Term Care Routine for Your Schaerer Coffee Machine

Maintaining a Schaerer coffee machine isn’t just about cleaning; it’s about creating a structured routine that preserves performance, flavor, and longevity. A proactive approach combining daily upkeep, periodic inspections, and professional Schaerer coffee machine repair ensures consistent coffee quality and reduces the risk of costly breakdowns. With the right care plan, your machine can deliver flawless beverages for years to come.

Key Takeaways:

-

Daily Attention Matters: Clean milk lines, brew units, and touchscreens to prevent buildup and maintain hygiene.

-

Water Quality Protects Components: Always use filtered or softened water and replace filters regularly.

-

Weekly and Monthly Checks Prevent Issues: Inspect grinders, seals, and brew units to catch wear early.

-

Lubrication and Calibration Are Essential: Keep moving parts smooth and grind settings optimized for flavor and performance.

-

Professional Servicing Ensures Reliability: Annual technician visits maintain warranty, update software, and replace worn components.

-

Monitor for Warning Signs: Unusual noises, leaks, or pressure changes indicate the need for prompt attention.

-

Proactive Care Saves Costs: A structured maintenance routine extends machine lifespan and keeps every cup consistent.

FAQs

How do I turn on and clean my Schaerer coffee machine?

To turn on your Schaerer coffee machine, plug it in, fill it with water and beans, and press the power button. For cleaning, empty the drip tray and grounds container, wipe the exterior, and run the automatic cleaning or milk system cycles.

What's the best way to descale a Schaerer coffee machine?

Use the manufacturer-recommended descaling solution and follow the machine’s automatic descaling program. Regular descaling prevents mineral buildup and keeps coffee tasting fresh.

Can I run vinegar through my Schaerer coffee maker to clean it?

It’s not recommended to use vinegar, as it can damage internal components and void your warranty. Always use a Schaerer-approved cleaning or descaling solution for safe maintenance.

How much does it cost to replace parts on a Schaerer coffee machine?

Small parts like O-rings, seals, and cleaning tablets cost $5–$30 USD, water filter heads around $140–$150 USD, and filter cartridges about $240 USD. Major components like brewing units, steam nozzles, or control panels typically range from $470–$945 USD depending on the model.