Groen Steam Kettle Troubleshooting: Smart Solutions for Busy Kitchens

Groen steam kettles are essential in busy kitchens, providing consistent heat and efficiency for large-scale cooking. But like any equipment, they can encounter issues that disrupt workflow and slow down meal prep. Knowing how to troubleshoot common problems quickly can save time, reduce stress, and keep your kitchen running smoothly.

Temperature fluctuations and steam pressure issues can disrupt even the busiest kitchens. Using genuine Groen steam kettle parts helps achieve consistent cooking temperatures, making it easier to prepare soups, sauces, stews, and other liquid-based dishes evenly, so every batch turns out perfectly. This guide provides practical tips to keep your steam kettle operating at its best.

How to Identify Common Groen Steam Kettle Problems in Busy Kitchens

Even well-maintained Groen kettles can experience subtle or unusual problems in high-volume kitchens. These issues are often overlooked until they cause efficiency or safety concerns. Identifying them early can prevent disruptions and prolong equipment life.

Common Groen Kettle Issues in High-Volume Kitchens

|

Problem |

Signs |

Solution |

|

Inconsistent Heat (Baffle Blockage) |

Uneven cooking, hot spots, food clustering |

Clean internal baffles; ensure proper water/steam flow |

|

Steam Condensation in Lid |

Water drips on food, condensation near hinges, and reduced steam efficiency |

Check lid seals, wipe condensation, ensure proper venting |

|

Corrosion at Joints/Fittings |

Rust, small leaks, metallic taste |

Inspect and replace corroded parts; use approved descaling agents |

|

Overheating from Residue |

Burnt smell, hot surfaces, burn marks |

Clean thoroughly after each use, especially corners/edges |

|

Faulty Tilt Sensor/Safety Interlock |

Kettle won’t tilt, interlock triggers, stops mid-cycle |

Inspect, adjust, or replace sensor/interlock; lubricate moving parts |

|

Air in Steam Lines |

Sudden steam bursts, inconsistent cooking, repeated resetting |

Bleed steam lines, check valves, and calibrate gauges |

Looking for a professional-grade steam kettle? Explore high-quality parts for restaurant equipment from PartsFe. We carry replacement valves, gaskets, thermostats, heating elements, lids, and more for top brands like Groen, Cleveland, Vulcan, and Southbend, with fast shipping available to keep your steam kettle reliable, safe, and cooking perfectly every time.

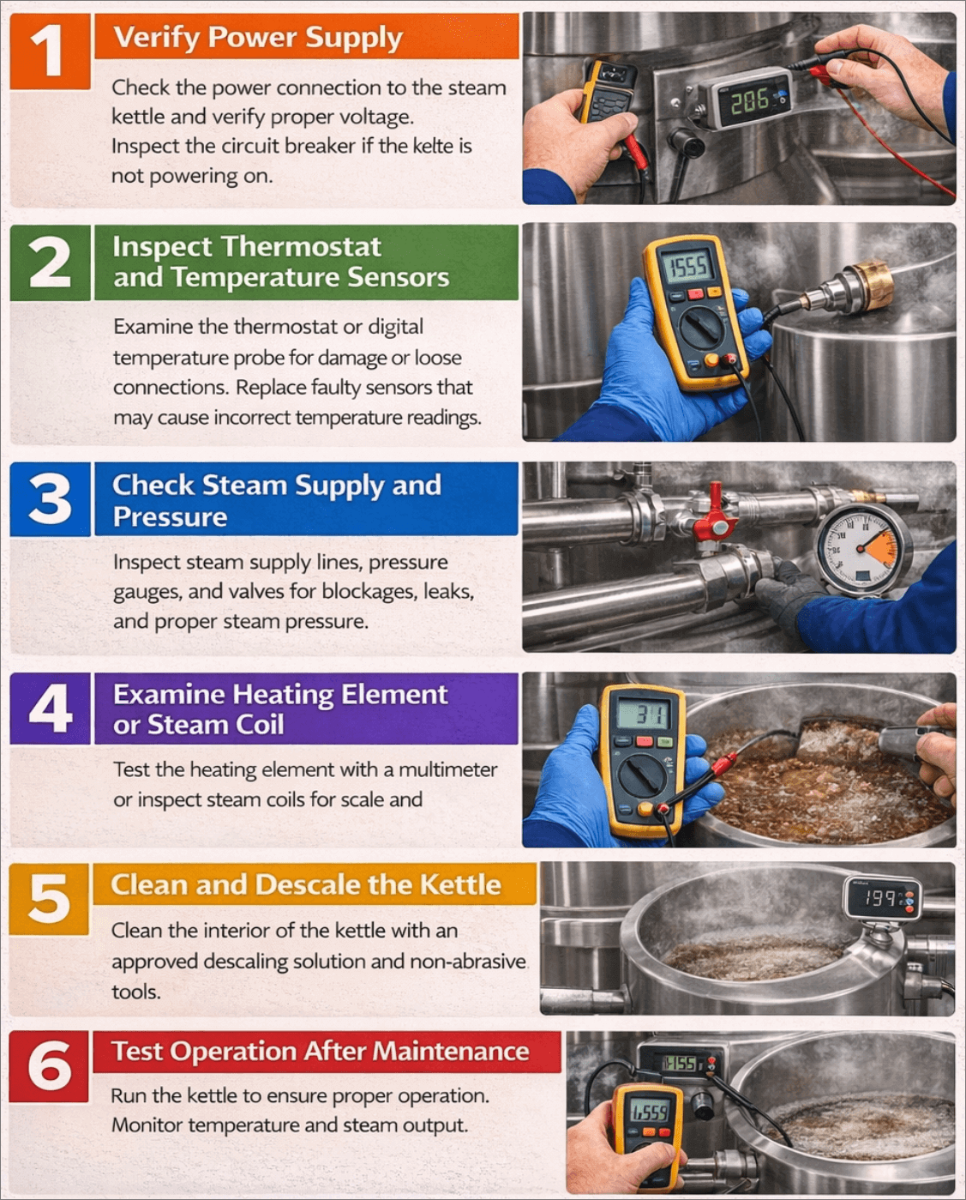

Tools and Safety Checks for Groen Steam Kettle Troubleshooting

Before performing Groen steam kettle troubleshooting, ensure you have the right tools and follow strict safety measures, as these units involve heat, steam, and electricity.

Essential Tools

-

Voltage tester or circuit analyzer

-

Hex keys and adjustable wrenches

-

Steam trap or pressure gauge tool

-

Digital surface thermometer or probe thermometer

-

Non-abrasive cleaning brushes and specialty cleaning pads

-

Insulated hand tools

Safety Checks

-

De-energize Fully: Switch off the breaker or disconnect the power at the source; don’t rely solely on the kettle’s on/off switch.

-

Verify Steam Pressure is Zero: Open the steam release valve and wait for residual pressure to dissipate before opening the lid.

-

Wait for Cooling: Even after draining, internal metal surfaces and liquid can remain dangerously hot for several minutes.

-

Wear Layered Protection: Heat-resistant gloves, long sleeves, and eye protection guard against splashes and steam burns.

-

Inspect Surroundings: Ensure no water spills, grease, or obstacles are near the kettle that could cause slips during inspection.

-

Check Safety Interlocks: Confirm that built-in kettle safety mechanisms (like lid locks or pressure sensors) are functioning before restarting.

By consulting the Groen steam kettle parts manual and following updated tools and safety checks, maintenance and troubleshooting can be done efficiently with minimal risk in a busy commercial kitchen.

How to Troubleshoot Temperature and Steam Issues in Groen Steam Kettles

Steam kettles can experience subtle temperature and steam problems that aren’t always obvious. Resolving these issues requires looking beyond the usual checks and understanding how pressure, sensors, and heat transfer interact in the kettle system.

|

Note: Groen steam kettles use high-capacity steam coils that can retain heat unevenly, creating hotspots even after normal cooldown. Avoid sudden tilting or stirring in concentrated areas to prevent splashing or scalding. Always verify internal pressure balance before adjusting valves or removing lids to protect both operator and equipment. |

When to Call a Technician for Groen Steam Kettle Issues:

-

Gradual Heating Delays: Kettle takes longer than usual to reach the target temperature.

-

Compensatory Cooking Adjustments: Staff must increase heat, stir more, or extend cook times to maintain consistency.

-

Uneven Tilt Resistance: Kettle tilts smoothly empty but resists movement under load, indicating pivot or frame stress.

-

Recurring Condensate Backup: Condensate drains normally at startup but returns mid-cycle, suggesting steam trap or internal valve issues.

-

Delayed Control Response: Input changes (temperature, tilt, agitator) respond slower than normal, signaling sensor or control board fatigue.

Fixing Electrical and Mechanical Problems in Groen Steam Kettles

Beyond temperature and steam concerns, issues like Groen steam kettle low water can occur with electrical and mechanical faults from constant heat, moisture, and heavy use.

Electrical and Mechanical Troubleshooting:

-

Unresponsive or Delayed Startup: Inspect terminal blocks and internal connectors for heat fatigue or oxidation, which can interrupt power flow even when breakers appear normal.

-

Inconsistent Heating Cycles: Evaluate sensor signal stability and control module response. Aging components may send delayed or inaccurate signals, causing uneven performance.

-

Electrical Odor or Tripped Protection Devices: Check for insulation breakdown or moisture intrusion inside control housings, which can lead to shorting under load.

-

Drips or Pressure Loss During Operation: Undetected leaks at spigots, lids, or internal joints often indicate seal compression failure rather than visible gasket damage.

-

Resistance During Tilting or Lid Movement: Examine pivot points, locking pins, and bearings for misalignment or mineral residue restricting motion.

-

Irregular Steam Flow: Internal valve wear or scale buildup may prevent full valve travel, reducing heating efficiency.

|

Disclaimer: The troubleshooting information in this article is provided for general informational purposes only. Electrical and mechanical repairs on Groen steam kettles can vary by model. This content is not a substitute for professional service or manufacturer guideline and is not responsible for any damage, injury, or operational issues resulting from the use of this information. |

Time-Saving Tips for Busy Kitchens:

-

Pre-portion and organize ingredients to minimize delays while troubleshooting kettles.

-

Batch cooking sauces or stocks helps maintain workflow even if the kettle is temporarily out of service.

-

Use multi-function equipment like tilting kettles or mixers to reduce handling time.

-

Checking for low water conditions early helps prevent sudden equipment failure during service.

Summary: Ensuring Reliable Operation and Optimal Performance of Groen Steam Kettles

Steam kettles can quietly develop subtle inefficiencies that affect workflow before obvious signs appear. Consistent monitoring of Groen Kettle temperature control, steam dynamics, internal pressure balance, and component interactions allows kitchens to prevent surprises, maintain precise cooking, and extend equipment life. Awareness of hidden hotspots, condensate patterns, and minor mechanical resistance keeps operations smooth and safe.

Key Takeaways:

-

Check for uneven heat zones caused by residual steam in high-capacity coils.

-

Monitor small leaks or seal compression issues that don’t trigger alarms.

-

Observe agitator and tilt mechanisms for minor friction or misalignment.

-

Track mineral buildup in valves and joints that gradually reduces efficiency.

-

Use workflow strategies like staging light vs. viscous liquids to avoid heat loss.

-

Schedule targeted component inspections rather than relying solely on routine cleaning.

FAQs

How to add water to a Groen steam kettle?

Ensure the kettle is off and fully depressurized. Pour water slowly into the kettle or designated fill port, avoiding overfilling.

Can I change the natural gas Groen steam kettle to propane?

Only with approved conversion kits and by a certified technician. Never attempt modifications without following manufacturer guidelines.

How to cook chili in a Groen EE-40 steam kettle?

Preheat the kettle to the desired temperature, add ingredients, and use the built-in agitator or gentle stirring for even cooking. Monitor steam pressure for consistent heat.