How to Clean Taylor Ice Cream Machine for Food Safety Compliance

Taylor ice cream machines are essential in restaurants, cafés, and ice cream shops, delivering creamy, consistent ice cream and frozen yogurt. Without proper cleaning, they can become breeding grounds for harmful bacteria like Listeria or Salmonella, putting customers at risk and threatening your business reputation. Regular checks of Taylor ice cream machine parts prevent ice crystal formation, help maintain consistent flavor and creaminess, ensuring each batch meets both quality and safety standards.

This guide walks you through a step-by-step cleaning process for your Taylor ice cream machine. We’ll highlight key components, explain proper sanitization techniques, and cover common mistakes to help maintain both safe operation and smooth, high-quality ice cream.

Why Food Safety Compliance Matters for Taylor Ice Cream Machines

Taylor ice cream machines combine refrigeration, mixing, and dispensing in one unit, making them highly complex. Even small lapses in cleaning or maintenance can create hidden hazards. Proper food safety compliance is essential to prevent contamination and ensure optimal performance.

Key Reasons to Prioritize Taylor Ice Cream Machine Cleaning:

-

Hidden Bacteria in Hard-to-Reach Areas: Beater shafts, mix hoppers, and internal tubing can trap leftover mix. These spots often escape routine cleaning, allowing bacteria to grow.

-

Biofilm Formation Risk: Residue can turn into a protective biofilm over time. Standard sanitizers may not reach it, contaminating future batches.

-

Cross-Contamination Between Flavors: Multi-flavor machines risk transferring allergens or bacteria. Thorough cleaning prevents accidental contamination between products.

-

Temperature and Timing Oversights: Improper cleaning can affect refrigeration efficiency. Slight temperature shifts create ideal conditions for microbial growth.

-

Undetected Mechanical Failures: Worn seals or cracks may hide under residue. Ignoring these issues compromises both hygiene and machine performance.

-

Mix Degradation and Off-Flavors: Residue buildup can alter flavor or texture over time. Compliance ensures every batch tastes fresh and consistent.

Wondering how to fix ice cream machine repairs affordably? Explore high-quality replacement parts & cleaning accessories for restaurant equipment from PartsFe for the best prices. We carry essential components like ice cream scoops, box lids, collars, and cabinet hinges from top brands like Taylor, Hamilton Beach, Schaefer, and Allpoints. Fast same-day shipping is available on eligible orders.

Taylor Ice Cream Machine Parts That Require Regular Cleaning

Understanding which parts of your Taylor ice cream machine require attention is essential for thorough cleaning. Each component plays a role in product quality and food safety compliance. Neglecting even small parts can lead to buildup, contamination, and mechanical issues.

Taylor Ice Cream Machine Parts That Must Be Cleaned Frequently:

|

Parts |

Why It Needs Cleaning |

Cleaning Tip |

|

Hopper, Lid, and Mixing Cylinder |

Residual mix can harbor bacteria inside the hopper and cylinder. |

Clean thoroughly after every shift using brushes to reach all surfaces. |

|

Beater, Spindle Assembly, and Drive Couplings |

Moving parts trap food particles and residue. |

Disassemble and scrub carefully to prevent bacterial growth and odors. |

|

Dispensing Nozzle and Handle |

High-contact areas that can spread bacteria. |

Sanitize daily to prevent cross-contamination and ensure customer safety. |

|

Seals, Gaskets, and Safety Valves |

Flexible components and valves trap mix and moisture. |

Remove and clean to avoid mold and biofilm formation. |

|

Drain, Drip Tray, and Drip Guard Underside |

Overflow areas collect mix and moisture, attracting mold and slime. |

Empty and sanitize regularly to prevent residue buildup. |

|

Air Intake Vents and Cooling Components |

Dust and debris reduce cooling efficiency and can introduce contaminants. |

Clean vents and fans thoroughly to maintain proper airflow. |

|

Cooling Plate Edges and Scratches |

Residue trapped in scratches can compromise hygiene and texture. |

Inspect and clean carefully to ensure consistent ice cream quality. |

|

Sensor Covers and Thermostat Housings |

Dust or mix buildup can interfere with temperature readings. |

Wipe and sanitize to maintain safe freezing conditions. |

By following strict food safety compliance, your ice cream maker water filter delivers consistent ice cubes every time.

|

Time-Saving Cleaning Technique: Rinse and rotate the machine components while cleaning to dislodge mix trapped in hard-to-reach crevices, preventing hidden bacterial buildup. Occasionally, run a hot-water cycle through the internal mix paths to flush out residues that standard brushing can miss. |

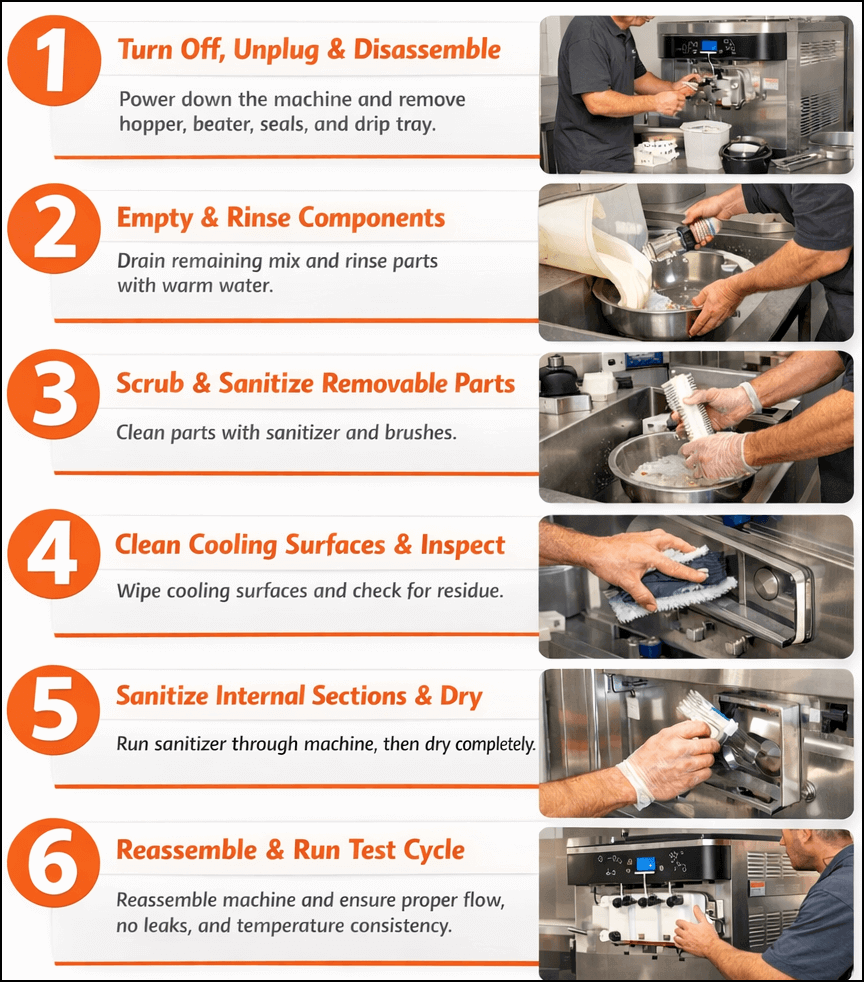

How to Clean Taylor Ice Cream Machine Step-by-Step

Proper cleaning of a Taylor ice cream machine is essential for food safety, consistent product quality, and equipment longevity. Skipping steps can lead to bacterial growth, off-flavors, and mechanical issues. A structured routine ensures every part is sanitized and the machine runs efficiently.

Tools and Supplies You’ll Need:

-

Taylor ice cream machine cleaning kit

-

Taylor ice cream machine cleaning brushes

-

Food-safe gloves

-

Protective goggles or a face shield

-

Apron or protective clothing

-

Non-slip shoes

-

Cleaning brushes (various sizes)

-

Sanitizing solutions

-

Buckets or containers

-

Lint-free cloths or paper towels

-

Drainage mats or trays

-

Temperature-proof gloves

Safety Guidelines:

-

Wear protective gear when handling cleaning chemicals.

-

Avoid direct contact with sanitizers and hot water.

-

Keep floors dry to prevent slips and falls.

-

Follow the manufacturer’s instructions for all cleaning solutions.

-

Inspect machine parts for damage before reassembly.

Step-by-Step Process for Taylor Ice Cream Machine Cleaning:

Find out Taylor ice cream machine troubleshooting: a busy chef’s guide for quick solutions to common machine problems.

Common Taylor Ice Cream Machine Cleaning Mistakes That Can Violate Food Safety Rules

Even experienced staff can unknowingly create hidden contamination risks when cleaning Taylor ice cream machines. Some mistakes aren’t obvious, occurring in micro-gaps, delicate sensors, or internal air paths. Avoiding these overlooked issues is key to full compliance and safe ice cream production.

Mistakes to Avoid During Taylor Ice Cream Machine Cleaning:

-

Overlooking Sensor Covers: Temperature or mix sensors may collect residue and moisture, causing inaccurate readings and hidden microbial growth.

-

Ignoring Air Intake Vents: Dust, powder, or mixed particles in vents reduce cooling efficiency and can contaminate internal components.

-

Misaligning Beater Shafts During Reassembly: Tiny gaps can trap mix, allowing fermentation and unseen microbial buildup.

-

Neglecting Flexible Gaskets in Corners: These soft areas can harbor mold if not fully removed, scrubbed, and dried.

-

Flushing With Water Only: Skipping sanitizer in internal mix paths leaves biofilm-prone surfaces untouched.

-

Storing Parts Damp or Stacked: Moisture between stored components can accelerate mold and bacterial colonization.

-

Using Uniform Brush Motion: Brushing only straight strokes misses angled channels and hidden drip guard folds, where bacteria can hide.

Best Practice: Never ignore subtle mechanical or hidden areas like small crevices behind the cooling plates or under the drip guard; residue in these spots can ferment quickly and become a contamination hotspot. Regularly inspect and clean these parts to ensure complete hygiene and machine safety.

Warning Signs Your Taylor Ice Machine Needs a Technician:

-

The machine consistently fails to freeze or cycles irregularly despite proper cleaning.

-

Motors, sensors, or control panels show repeated errors or mechanical issues.

-

Cracked cylinders, damaged gaskets, or worn internal parts are detected.

-

Mold or biofilm persists in hidden areas even after full cleaning.

-

Preventive maintenance is due or the machine shows high-usage wear.

Summary: Maintaining Long-Term Food Safety Compliance

Regular and thorough cleaning of Taylor ice cream machines is essential to protect customers, ensure product quality, and comply with food safety regulations. Attention to hidden areas, proper tools, and following a structured routine prevents bacterial growth and equipment issues. Implementing best practices consistently guarantees both hygiene and machine longevity.

Key Takeaways:

-

Always follow a step-by-step cleaning routine for all removable and non-removable parts.

-

Use proper tools and personal protective equipment to ensure safety.

-

Pay attention to hidden areas like sensors, vents, gaskets, and drip guards.

-

Avoid common mistakes such as skipping sanitizer or storing parts damp.

-

Inspect machine components regularly for wear, residue, or damage.

-

Consistent cleaning practices maintain high-quality ice cream and long-term food safety compliance.

FAQs

How often should I clean my Taylor ice cream machine?

Taylor ice cream machines should be cleaned daily to prevent bacterial buildup and maintain food safety compliance. Some parts may also require a deep weekly cleaning for optimal hygiene.

Should I run vinegar through my Taylor ice cream machine to clean it?

No, using vinegar is not recommended, as it can damage seals and internal components. Always use food-safe detergents and sanitizers specified by Taylor.

Why is my Taylor ice cream machine freezing up?

Freezing issues often result from improper mix temperature, low mix levels, or clogged components. Regular cleaning and following manufacturer guidelines can prevent freezing problems.

|

Disclaimer: This guide is for informational purposes only and does not replace the official Taylor ice cream machine manual. Always follow the manufacturer’s instructions and safety guidelines when cleaning or servicing the machine. |