Common Issues in Commercial Gas Grill Burner and How to Fix Them Quickly

Commercial gas grills are essential tools in busy kitchens, especially in restaurants and catering services. However, like any equipment, they can experience issues that disrupt operations and impact food quality. Gas grill burner problems, being the heart of a gas grill, are often the most common source of these issues. Recognizing them early and knowing how to fix them can save time, money, and frustration.

From uneven heating and low flames to complete burner failure, many problems have simple solutions if diagnosed correctly. Regular maintenance and quick troubleshooting can extend the life of your gas grill burner and ensure consistent performance. In this guide, we’ll cover the most frequent burner issues in commercial gas grill and provide fast, practical fixes to keep your kitchen running smoothly.

Understanding Commercial Gas Grill Burners: Key Components and Function

Commercial burners for a gas grill operate by mixing gas and oxygen to produce a controlled flame used for cooking. These burners are usually made of stainless steel, cast iron, or aluminized steel for durability and heat retention.

-

Burner Tubes: These are the metal tubes (often stainless steel or cast iron) that deliver the gas/air mixture and house the flame ports.

-

Flame Ports (or Burner Holes): Small precisely‐drilled holes in the burner tube that allow the gas/air mixture to exit and ignite, forming flame lines.

-

Venturi Tubes / Air-Mixing Channels: The passages that mix ambient air with the gas stream, enabling proper combustion.

-

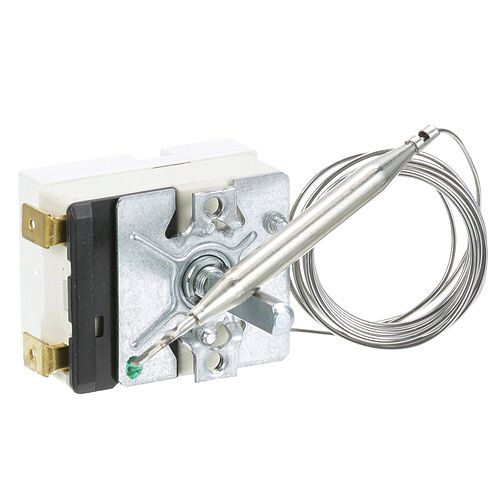

Orifice or Jet and Valve: The gas supply enters via a valve/orifice, which regulates the pressure and flow of the gas before reaching the burner.

-

Ignition System: Could be a pilot light, hot surface ignitor, or spark electrode that triggers flame ignition.

-

Heat-Distribution Components: In commercial units, flame deflectors, radiant plates, or flavorizer bars sit above burners to distribute heat evenly and protect the tubes.

-

Grease/Drip Tray and Catch Pan: These collect the grease and residue from the cooking surface and are critical to safe operation.

Regular inspection and replacement using genuine gas grill replacement burners can prevent common issues such as uneven heating, low flames, or burner failure.

Check out this guide on griddle & grill: understanding the role of gas grill pressure regulators to ensure safe, efficient fuel flow and optimal grilling performance.

Looking for replacement parts to fix your commercial gas grill burners fast? PartsFe offers high-quality parts like burner tubes, ignitors, and burner valves from leading brands like Pitco, Southbend, and Garland to keep your grill running smoothly!

Common Burner Clogs and Blockages: Causes and Prevention

Blockages in gas grill burners are common, especially in commercial or seldom-used grills. Knowing the causes and prevention helps keep your grill working efficiently.

Causes of Blockage and Their Prevention:

Insect Nests: Spiders and wasps build nests inside venturi tubes or burner ports, restricting airflow.

Prevention: Regularly inspect and clear venturi tubes of webs or nests, especially after periods of inactivity.

Grease and Food Debris: Buildup in burner tubes and ports blocks gas flow.

Prevention: Clean burner tubes and flame ports monthly (or more often for heavy use) using wire or venturi brushes and small tools like toothpicks.

Corrosion and Rust: Moisture and acidic residues cause rust, damaging burner ports.

Prevention: Keep burners dry, cover the grill when not in use, and replace corroded parts promptly.

Orifice Misalignment or Damage: Misaligned or damaged orifices disrupt the gas/air mix.

Prevention: Inspect orifices during maintenance and ensure proper alignment or replace damaged parts.

Clogged Grease Trays: Overflowing grease trays cause flare-ups and residue buildup on burners.

Prevention: Empty and clean grease traps and drip pans regularly to prevent buildup and flare-ups.

By addressing each cause with targeted prevention, you’ll keep your grill firing safely and efficiently every time.

Signs Your Commercial Gas Grill Burner Needs Attention

Here are common symptoms to watch for. If you notice any gas grill burner not working, it’s time for inspection, cleaning, or repair.

-

Gas Grill Burner Won’t Light: The ignitor sparks, but the burner fails to sustain a flame.

-

Weak Flame or Flame Only at One End: The flame is low, sputtering, or only present in certain parts of the burner.

-

Uneven Flame Distribution: Some flame ports have strong flames, others have none, or flames appear yellow/orange instead of blue.

-

Flame Coming Out of Unusual Places: Gas flare-ups from the back of the burner tube or holes on the sides, often due to corrosion.

-

Popping or Sputtering When Lighting: Indicates delayed ignition or improper air/gas mixture.

-

High Fuel Usage or Longer Cook Times: Shows inefficiency, often caused by poor combustion or blocked ports.

Recognizing these signs early helps maintain safe and efficient grill operation.

Dealing with Uneven Flame Distribution in Commercial Grills

To effectively manage uneven flame distribution, consider these important and often overlooked points:

-

Identify and Clear Partial Blockages: Even minor debris or partial clogs in specific burner ports can cause uneven flames; use a magnifying glass or flashlight to spot less obvious blockages.

-

Assess Flame Color and Shape: Uneven flames may show color shifts or flickering. Use these visual cues to pinpoint problem areas before deeper cleaning.

-

Check Gas Pressure Consistency: Low or fluctuating gas pressure often leads to uneven flames; test regulator settings and gas supply lines for stability.

-

Evaluate Ambient Air Intake: Excess or insufficient air mixing through venturi tubes can cause flame irregularities; adjust air shutters if your grill model allows it.

-

Rotate and Test Burners: Sometimes rotating burner positions (if possible) helps isolate if uneven flames are due to a faulty burner or gas supply issue.

-

Schedule Preventative Maintenance Around Usage: Heavy-use commercial grills may require more frequent inspections based on cooking volume rather than calendar time alone.

By applying these focused strategies, you can not only fix uneven flames but also extend the lifespan and efficiency of your commercial grill.

Ignition Problems: Troubleshooting Spark and Pilot Issues

When your burner won’t light or ignition is inconsistent, the problem usually lies in the ignition or pilot system rather than the burner ports themselves. Here’s a quick guide for Gas Grill Burner troubleshooting and what to check.

Common Ignition Issues:

-

No Spark or Weak Spark: The ignitor button doesn’t produce a visible spark, or the spark is weak.

-

Dirty or Misaligned Electrode: Grease buildup or dirt on the electrode or ignition area can block the spark; the electrode may also be out of position.

-

Pilot Light Won’t Stay Lit: Could be caused by a faulty thermocouple, airflow issues, or gas flow problems (in models with a pilot).

-

Gas Supply Issues: The ignitor may spark, but if gas flow is insufficient due to valve, regulator, hose, or orifice problems, the flame won’t sustain.

-

Delayed Ignition (Popping Sound): Indicates gas delay reaching the burner, air in the gas line, or partial blockage.

Troubleshooting Steps:

-

Turn off the gas supply and disconnect power if applicable.

-

Clean the electrode and ignitor wire to remove carbon, grease, and debris.

-

Ensure the electrode is positioned correctly according to manufacturer specs, close enough to the burner flame port for a proper spark.

-

Press the ignition button and visually check for spark; if none, test or replace the ignitor module or battery.

-

Test gas flow by turning on the burner with the lid open—no flame indicates a possible valve, regulator, hose, or orifice issue.

-

Inspect the pilot system (if present); clean the thermocouple and make sure it’s properly aligned, and clear the pilot orifice.

-

Clear the air from the gas line by turning burners to high with the lid open for a few minutes, especially after long idle periods or cylinder changes.

-

Reconnect the system and test ignition; the flame should ignite quickly, remain steady, and burn cleanly.

Following these steps should help resolve most ignition issues and get your grill lighting reliably again.

Corrosion and Wear: When to Repair or Replace Burners

Gas grill burners face heat, moisture, grease, and food acids, causing corrosion and wear. Knowing when to repair or replace them is essential for safe, efficient grilling.

Signs of Corrosion and Wear:

-

Surface rust that may progress to pitting and flaking

-

Cracks or holes in burner tubes caused by metal fatigue or corrosion

-

Warped or bent burners due to repeated heat cycles

-

Enlarged or deformed flame ports affecting flame quality

-

Uneven flames or poor heat distribution during use

When to Repair:

-

Minor surface rust or discoloration

-

Blocked or clogged flame ports that can be cleaned

-

Small flame port damage or slight surface wear

When to Replace:

-

Visible holes, cracks, or severe corrosion

-

Significant flame port erosion or deformation

-

Warped burners that no longer fit securely

-

Corrosion near the gas orifice is causing unsafe gas flow

Proper maintenance and timely repairs or replacements keep your grill safe and performing at its best.

Quick Fixes and Maintenance Tips for Long‑Lasting Burner Performance

Regular upkeep and prompt fixes are key to extending the life of your commercial gas grill burners. Simple maintenance tasks like gas grill burner cleaning can prevent costly repairs and ensure consistent cooking performance.

-

If flame is weak or uneven: clean burner ports, inspect for blockages, realign burner tube, replace parts if cracked.

-

If the burner won’t light: clean the ignitor electrode, test gas supply, clear any venturi obstructions, and check the regulator.

-

If flame is yellow or orange: shut down, inspect for ventilation/air intake issues, clean vents/ports, check for air starvation.

-

If you see rust or holes: mark the burner for replacement and order a correct part; until then, reduce usage or take that burner offline.

-

Use a gas grill burner cleaning brush (venturi brush, wire brush) rather than general cleaning tools. The right tool helps speed the job and reduce the risk of damage.

-

Consider using a maintenance kit or spare parts set (burner tubes, ignitor, and/or orifice) so you can swap quickly during service downtime.

Daily (or after each shift/use):

-

Scrape and wipe the cooking surface and grates to remove food debris, grease, and char.

-

Empty and clean the grease and drip tray to prevent overflow and flare-ups.

Weekly/Bi-weekly:

-

Remove and clean the flame deflectors and radiant plates, and inspect burner tubes for rust or debris.

-

Check hoses, regulators, and gas connections for leaks by applying a soap and water solution and looking for bubbles.

Monthly:

-

Remove burners (if possible) and thoroughly clean burner tubes, ports, and venturi tubes while inspecting for damage or corrosion.

-

Test the flame pattern to ensure even blue flames with small yellow tips and no weak spots.

-

Inspect the ignition system, including electrode, spark, and pilot components, to confirm reliable performance.

Seasonal/Quarterly (for heavy-use commercial grills):

-

Replace or overhaul burners if you observe signs of wear or corrosion.

-

Perform a deep clean of the grill interior by removing cooking grids, burners, trays, scrubbing surfaces, and checking drain lines and ventilation.

-

Document all maintenance activities, issues found, and parts replaced to track costs and lifecycle.

Check out this guide on grill temperature control on commercial gas grills to master precise heat management for consistent cooking results.

How Proper Burner Function Ensures Safe and Efficient Grilling

Safe grilling starts with burners that work correctly. When burners perform well, flames stay steady and even, ensuring food cooks thoroughly and safely.

-

Uneven or weak flames can cause flare-ups or undercooked food, risking safety and quality.

-

Proper combustion reduces harmful emissions and prevents gas leaks or carbon monoxide buildup.

Understanding how burners operate helps you spot problems early and avoid dangerous situations. A well-functioning grill saves fuel, cooks better, and keeps everyone safe during every cookout.

FAQs

Why is my gas grill not getting gas to the burners?

A common cause is a tripped safety device in the regulator or a closed propane tank valve. Check connections, open the valve fully, and reset the regulator if needed.

How to clean clogged burners on a gas grill?

Remove the burners and use a brush or thin wire to clear out debris from the ports. Rinse with water and dry completely before reattaching.

How to reset the propane regulator on the grill?

Turn off the gas tank and disconnect the regulator for about 30 seconds. Reconnect it, open the tank valve slowly, then relight the grill.

How to tell if a grill regulator is bad?

If your grill won't heat properly, shows weak flames, or makes popping sounds, the regulator may be faulty. Try a reset first; if problems persist, consider replacing it.