How to Choose the Right FrenchFry Cutters for Commercial Kitchens

In a commercial kitchen, speed and consistency are essential for keeping up with customer demand, especially when it comes to preparing high-demand items like french fries. The right french fry cutter can significantly streamline the preparation process, ensuring uniform cuts and reducing labor time. With various models available, manual, electric, or even commercial-grade options, choosing the right cutter depends on your kitchen’s specific volume, space, and fry preferences. A well-chosen cutter not only boosts efficiency but also ensures quality and consistency in every batch. This guide will explore the key factors you should consider when selecting a french fry cutter, helping you choose the best tool to meet the needs of your busy kitchen.

Understanding the Role of French Fry Cutters in Commercial Kitchen Operations

French fry cutters are essential tools in commercial kitchens, providing efficiency, consistency, and safety in preparing one of the most popular menu items, fries. Here’s how they contribute to kitchen operations:

-

Speed and Efficiency: French fry cutters automate the slicing process, saving time and increasing efficiency, especially during peak hours.

-

Consistency and Uniformity: Cutters ensure fries are uniformly sliced, leading to even cooking and consistent product quality.

-

Increased Productivity: With faster potato processing, french fry cutters help increase kitchen throughput, enabling restaurants to serve more customers in less time.

-

Improved Safety: Using cutters reduces the risk of knife-related injuries, creating a safer work environment for kitchen staff.

-

Customization for Menu Variety: Interchangeable blades allow for different fry styles (e.g., crinkle, waffle), giving kitchens the flexibility to cater to diverse customer preferences.

-

Consistency in Portion Sizes: Uniform cuts lead to consistent portion sizes, making it easier to control portions and minimize food waste.

These benefits make french fry cutters a crucial tool in maintaining kitchen efficiency, food quality, and safety.

Looking for the perfect french fry cutter for your commercial kitchen? At PartsFe, we offer high-quality cutters like blade assemblies, pusher blocks, and cutting blades to keep your equipment running smoothly. Choose from top brands like Nemco, Vollrath, and Winco to ensure efficiency and precision in every cut.

Types of FrenchFry Cutters for Commercial Kitchens

Selecting the right french fry cutter depends on factors like fry volume and desired fry styles. Here's a breakdown of the most common cutter types and their benefits:

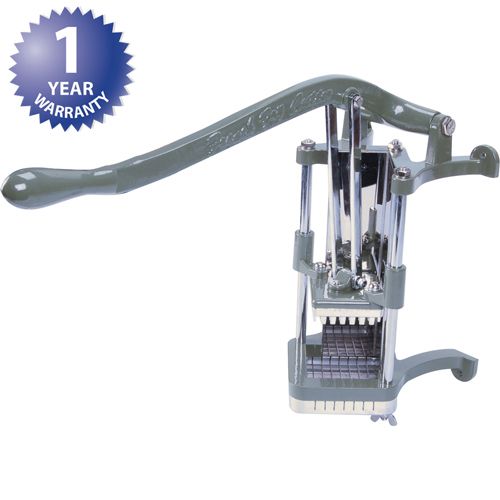

Manual FrenchFry Cutters

-

Best for Low & Medium Volume Kitchens: Ideal for establishments with occasional fry prep needs.

-

Effort Required for Operation: Manual cutters require physical force, which may slow down high-volume operations but offers more control over the cut.

-

Affordable and Space-Efficient: Budget-friendly and compact, these cutters are perfect for small businesses with limited kitchen space.

-

Ideal for Smaller Businesses: Suitable for cafes, diners, and smaller food outlets that don’t require constant fry prep.

Electric FrenchFry Cutters

-

Best for High-Volume Kitchens: Perfect for operations with consistent fry demand, like fast-food chains and large restaurants.

-

Speed and Efficiency: Electric cutters can process large quantities of potatoes quickly, cutting down on prep time.

-

Higher Cost: Though more expensive, electric models save time and labor costs in busy kitchens.

-

Suitable for High-Demand Environments: Great for food trucks, fast-casual restaurants, or kitchens serving large crowds.

Heavy-Duty FrenchFry Cutters

-

Durability for High-Volume Use: Designed for heavy-duty use, these cutters are built to handle high volumes and frequent operation in busy kitchens.

-

Designed for Large Quantities: These cutters can handle large batches, ensuring you’re ready for rush hours.

-

Made with Commercial-Grade Materials: Constructed with tough, long-lasting materials to minimize wear and tear.

-

Best for Large Kitchens: Perfect for commercial kitchens that regularly serve fries in bulk, like catering businesses and large food courts.

Vertical Cutters:

-

Compact Design: Cut potatoes from top to bottom, and they are often more compact and easier to store.

-

Ease of Use: Ideal for smaller kitchens with limited space, horizontal cutters are simple for operators to handle, making food prep quicker and more efficient.

Horizontal Cutters:

-

Higher Volume Capability: These cutters often handle larger volumes of potatoes at once.

-

Better Control for Thicker Cuts: Ideal for kitchens that need thicker fries, offering more control over the size of the cut.

Choosing the right potato french fry cutter type ensures faster, more consistent results and helps maintain kitchen efficiency and quality.

Key Features to Consider When Choosing a frenchFry Cutter

When selecting the best french fry cutters for your commercial kitchen, it’s important to evaluate specific features that can enhance efficiency and improve the consistency of your fry prep. Here are the key factors to keep in mind:

Blade Quality and Variety

-

Stainless Steel Blades: French fry cutter blades provide long-lasting sharpness and resist rust in a busy kitchen environment.

-

Interchangeable Blade Options: Allows you to switch between fry shapes like straight, crinkle, or shoestring without buying multiple cutters.

-

Easy Blade Replacement: Blades that can be swapped without special tools save time during maintenance.

Build Material

-

Heavy-Duty Frame: Cast iron, stainless steel, or reinforced aluminum frames withstand constant commercial use.

-

Avoid Weak Materials: Frames made of thin metal or plastic may bend or break when subjected to pressure.

-

Reinforced Components: Sturdy levers and strong joints help the cutter perform reliably over time.

Cutting Capacity

-

Potato Size Compatibility: Ensure the cutter can handle your preferred potato size without extra trimming.

-

Match Volume Needs: Choose a capacity that meets your busiest service times.

-

Batch vs. Continuous Feed: Decide between models designed for single batches or ongoing potato feeding.

Ease of Cleaning

-

Removable Parts: Detachable parts make cleaning quicker and more efficient.

-

Smooth Surfaces: Non-porous materials prevent food buildup and bacterial growth.

-

Dishwasher-Safe Components: Saves time on cleaning during peak hours.

Safety Features

-

Non-Slip Base or Mounting: Keeps the cutter stable during use.

-

Blade Guards: Protects hands from accidental contact with sharp edges.

-

Ergonomic Handles: Reduce operator strain during repetitive tasks.

Space and Mounting Options

-

Wall-Mounted Models: Ideal for saving counter space in compact kitchens.

-

Portable Countertop Models: Can be moved and positioned as needed.

-

Compact Footprint: Ensures the cutter fits into your existing prep space without clutter.

Check out our guide on ventless deep fryers: the future of commercial kitchens to learn how these fryers can help save space, reduce energy costs, and streamline kitchen workflows.

Common Mistakes to Avoid When Selecting a FrenchFry Cutter for Your Kitchen

Choosing the wrong french fry cutter can lead to wasted money, reduced efficiency, and inconsistent results. Avoid these common pitfalls to ensure you invest in a tool that truly meets your kitchen’s needs:

-

Ignoring Volume Requirements: Buying a small-capacity cutter for a high-demand kitchen will slow down operations and cause delays.

-

Overlooking Blade Quality: Low-grade blades dull quickly, leading to uneven cuts and higher replacement costs.

-

Choosing the Wrong Type: Selecting a manual cutter for high-volume output or an electric model for occasional use can result in inefficiency and wasted investment.

-

Neglecting Maintenance Needs: Some cutters require complex cleaning and upkeep, and overlooking this can shorten their lifespan.

-

Not Considering Space Constraints: A bulky model may disrupt your kitchen layout, making prep areas crowded and unsafe.

-

Skipping Safety Features: Lack of blade guards or non-slip bases increases the risk of accidents.

-

Ignoring Warranty and Support: Without quality after-sales service, repairs and replacements can become costly and time-consuming.

By avoiding these mistakes, you’ll ensure your french fry cutter delivers consistent performance, durability, and efficiency in your commercial kitchen.

Preventative Maintenance Tips for Commercial French Fry Cutters

Proper maintenance is essential for prolonging the life of your commercial french fry cutter and maintaining its performance. Here are essential maintenance tips:

-

Clean After Every Use: Wash removable parts with warm, soapy water to remove grease and food debris. Thoroughly dry parts to prevent rust and bacterial growth.

-

Inspect Blades Regularly: Check for dullness, chips, or bent edges that affect cutting quality. Replace blades when necessary to maintain uniform fries and prevent damage to the cutter.

-

Lubricate Moving Parts: Apply food-safe lubricant to hinges, pivots, and levers. Regular lubrication minimizes friction, preventing wear and ensuring smooth function.

-

Tighten Loose Components: Check screws, bolts, and brackets to make sure they’re properly secured. Loose components can cause instability and lead to performance issues.

-

Avoid Overloading: Cut large potatoes into smaller pieces to avoid straining the cutter. Overloading can cause wear on the blades and frame.

-

Use a Soft Brush for Cleaning: A nylon brush can help remove food residue from tight spaces without scratching surfaces, maintaining cleanliness and cutter integrity.

-

Store in a Dry Location: Store the cutter in a dry place to prevent rust and corrosion, protecting metal parts.

-

Follow Manufacturer Guidelines: Refer to the manual for proper cleaning and maintenance schedules to keep the cutter in optimal condition.

By following these tips, you’ll ensure your french fry cutter operates efficiently and lasts longer.

Check out this guide on how to clean commercial deep fryers to ensure optimal performance and extend their lifespan.

Conclusion

A well-chosen french fry cutter can transform the efficiency and quality of fry preparation in a commercial kitchen. By selecting a model that matches your volume, space, and menu needs while considering features, avoiding common mistakes, and following proper maintenance, you ensure consistent results, reduced downtime, and a longer equipment lifespan. With the right cutter and care, your kitchen can meet demand smoothly, maintain food quality, and keep customers coming back for perfectly cut, delicious fries every time.

FAQs

What are the different types of french fry cuts?

There are several types of french fry cuts, such as julienne, crinkle-cut, steak fries, shoestring, and waffle fries. Each cut offers a unique texture and cooking style, perfect for different menu items.

Which type of french fry cutter is best for a high-volume commercial kitchen?

For high-volume kitchens, look for a heavy-duty french fry cutter with stainless steel blades and a sturdy frame. Popular options include models from Nemco and Vollrath, known for their reliability and performance under pressure.

Can a french fry cutter be used for other vegetables?

Yes, many french fry cutters can be used for other vegetables like carrots, zucchini, and sweet potatoes. However, make sure to check the cutter's specifications, as some are designed specifically for potatoes.

How do I choose the right blade size for my french fry cutter?

The blade size you choose depends on the style of fries you want to serve. For thinner fries, opt for smaller blades, and for thicker fries like steak fries, go for larger blades that can handle more substantial cuts.

How do you use a French fry cutter?

Place a washed, peeled potato in the cutter tray and press the handle down firmly. The potato will be pushed through the blades, slicing it into uniform fries.