Hobart Slicer Parts Troubleshooting: How to Fix Common Issues

Hobart slicers are known for their durability and precision in commercial kitchens, but like any piece of equipment, they can occasionally run into issues. Whether you're slicing meats, cheeses, or vegetables, ensuring your Hobart slicer operates smoothly is essential for efficiency and safety. In this guide, we'll walk you through some common troubleshooting steps to help you fix frequent problems that may arise with your Hobart slicer parts. From difficulty with the blade to motor issues or malfunctioning safety features, we’ve got you covered. Knowing how to address these problems can save you time and money, ensuring your Hobart slicer stays in top working condition. Read on for practical solutions to keep your Hobart slicer performing at its best.

Understanding Your Hobart Slicer Parts and Their Functions

Learning about all Hobart slicer parts enables you to perform maintenance and solve issues effectively. The slicer operates efficiently through its individual components which perform specific functions to deliver consistent results. The main components of Hobart slicers function as described below:

-

Blade: The Hobart slicer blade functions as the main component that produces exact cuts. The blade needs to maintain its sharpness to achieve clean cuts on all types of food including meats, cheeses and vegetables.

-

Motor: The motor drives the slicer through its movements to power the blade for efficient slicing operations. A powerful motor enables smooth operation but a faulty motor can result in slicer stalling or slowing down or preventing start-up.

-

Feed Tray: The feed tray functions as a holding chamber for food items before they reach the blade to achieve precise cuts. A properly placed feed tray guides food items without interruptions which leads to uniform slice quality.

-

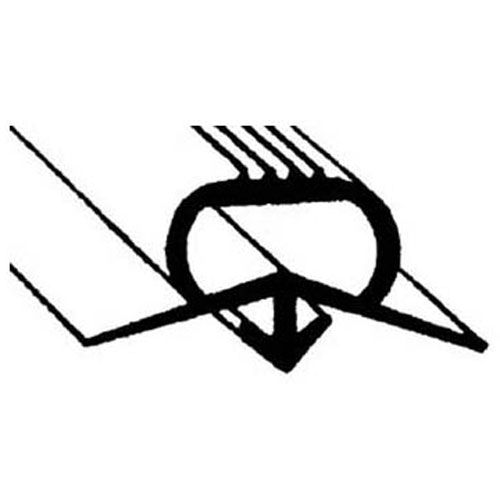

Carriage: The carriage system directs food items directly to the blade to produce uniform and exact cuts. The carriage needs to move without resistance on the rails because any blockage or misalignment will produce irregular slices and subpar performance.

-

Food Pusher: The food pusher assures smooth safe delivery of food to the blade for producing even pressure that leads to uniform slices. A malfunctioning food pusher can create uneven cuts and potentially result in severe injuries to users.

-

Adjusting Knob: Users can achieve precise slice thickness through the adjusting knob which provides control for different food items. The knob's functionality to adjust slice thickness will be impaired when it becomes stuck or damaged which may lead to repair or replacement needs.

At PartsFe, we ensure your kitchen equipment operates flawlessly with our extensive selection of high-quality replacement parts. Explore our range of Hobart slicer components, including blades, Sharpening Stones, transmission gears, and carriage slides, all designed to keep your slicer performing at its best. Trust PartsFe for reliable parts that deliver consistent results.

Identifying Common Issues with Hobart Slicers

The initial step to maintain smooth Hobart slicer operation requires identifying standard equipment problems. Addressing the problems when they are still minor will stop more serious breakdowns from happening in the future. The most common problems that affect Hobart slicer parts require examination.

-

Dull or Damaged Blade: The Hobart Slicer Blade loses its sharpness and develops damage which results in rough and irregular cuts. Blake operation becomes more challenging because of this condition leading to inconsistent slice sizes and quality perception. A damaged blade creates operational safety hazards while in use.

-

Motor Malfunctions: Hobart slicers often experience motor-related problems as one of their main operational issues. The performance of your Hobart slicer suffers when its motor does not start or operates with reduced power or produces abnormal noises. The equipment malfunctions because of electrical problems combined with wear and overheating conditions.

-

Sluggish or Stuck Carriage: The carriage system which feeds food to the blade will slow down slicing performance when it becomes slow or gets stuck. The combination of dirty equipment and insufficient lubrication and deteriorating components creates movement problems which produce irregular slices.

-

Food Getting Stuck: Food items that become stuck or misaligned inside the slicer device will result in irregular slicing and potentially stop the machine from operating correctly. The feed tray obstruction together with misalignment and improper food handling are the main causes of this problem.

-

Thickness Adjustment Problems: The slicer's ability to change slice thickness depends on the proper functioning of the thickness control knob which should not get stuck. The inconsistent cuts from this problem affect both the quality of the slices and the slicer's operational efficiency.

Identifying potential issues at their first signs allows you to take appropriate Hobart slicer maintenance steps that improve its operational excellence.

Also read on: Globe Meat Slicer Parts Troubleshooting: Here's How to Fix

Hobart Slicer Parts Troubleshooting: Step-by-Step Guide to Fixing Common Issues

Your Hobart slicer creates workflow interruptions when it faces operational problems. The ability to perform Hobart slicer troubleshooting and fix standard Hobart slicer component issues enables quick and efficient maintenance. This guide presents a clear sequence of instructions to handle standard slicer issues that will restore your equipment to optimal performance.

Dull or Damaged Blade

A blade that is dull or damaged will result in irregular cuts that make food slicing more difficult.

Solution: Safety first requires you to disconnect the slicer from power while it rests with the blade turned off. Check the blade for any visible damage as well as chips or signs of dullness. Replace the blade with a new one whenever sharpening fails to restore the edge because this ensures both optimal performance and safety during operation.

Motor Malfunctions

The electrical system or mechanical wear can cause the motor to either stop working or operate at reduced speed.

Solution: Make sure the slicer has proper power connection and that the power switch operates correctly. Check for heat-related issues and listen for abnormal equipment sounds. Check the power cord for damage before deciding to replace the motor or seek professional help for repairs when the motor does not work. Press the Hobart slicer reset button to fix electrical problems that might be present.

Sluggish or Stuck Carriage

Food movement problems caused by a carriage that operates slowly or gets stuck will negatively impact the accuracy of slice cuts.

Solution: Check and clean the carriage together with the rails to eliminate food particles as well as dirt and grease buildup. Apply food-safe lubricant on the rails to achieve smooth rail movement. Examine the alignment and check for worn components before replacing damaged parts to achieve smooth accurate slicing.

Food Getting Stuck

The slicer's operation slows down when food becomes trapped inside resulting in irregular slice dimensions.

Solution: Remove any blockages from the feed tray while ensuring it remains properly aligned to prevent misfeeding. Examine the food pusher to verify it has no cracks or breaks that would stop it from moving food properly. The feed tray alignment should be adjusted to let food glide smoothly toward the blade for producing uniform and clean slices.

Thickness Adjustment Problems

The control knob and internal components become damaged or malfunctioning to cause problems with adjusting the slice thickness.

Solution: Check the thickness control knob for external damage while cleaning the adjustment mechanism to prevent blockages. Check the internal parts of the adjusting mechanism for wear and replace any worn components to ensure accurate slice thickness control when the knob becomes unresponsive or stuck.

Consult your Hobart Slicer Manual for solutions to standard problems so you can bring your slicer to peak operational performance. You must always respect safety protocols whenever completing repairs or maintenance tasks.

Signs It’s Time to Replace Hobart Slicer Parts

Hobart slicers maintain their durability but eventually require replacement of their components. Sustaining your Hobart slicer will require replacement of specific components so you can avoid high maintenance costs and preserve its operational lifespan. The following signs indicate your Hobart slicer parts need replacement:

-

Persistent Dullness or Damage to the Blade: The blade needs replacement when blade sharpening fails to restore cutting ability or when the blade shows visible damage through chipping or cracking. A damaged blade produces uneven slices while simultaneously presenting safety dangers to users.

-

Motor Overheating or Failure: The motor needs replacement when it continues to overheat or fail to operate after performing standard troubleshooting procedures. A faulty motor will decrease the slicer's operational efficiency until it eventually stops working completely.

-

Excessive Wear on the Carriage: The carriage needs new bearings or complete replacement when it shows signs of misalignment or sluggishness or gets stuck even after regular cleaning and lubrication procedures.

-

Food Pusher Damage: A severely damaged or cracked food pusher cannot perform its safety functions correctly which results in unsafe food cutting operations.

-

Thickness Control Issues: A damaged or stuck or non-functional thickness control knob on the slicer requires a new control mechanism to achieve precise slicing.

The replacement of worn-out parts at the right time allows your Hobart slicer parts to operate efficiently and safely while preserving their high performance levels in your kitchen.

Preventative Cleaning and Maintenance Tips to Avoid Hobart Slicer Issues

The proper maintenance schedule along with regular cleaning operations ensure your Hobart slicer operates optimally while avoiding typical breakdowns. The implementation of these preventive measures will help your slicer last longer while preventing expensive Hobart Slicer repairs.

-

Daily Cleaning: The slicer requires complete cleaning after every use to eliminate food debris and grease and remaining residue. Wash the Hobart slicer with warm soapy water using a soft cloth while focusing on cleaning the blade and feed tray and carriage. A slicer that remains clean operates better while simultaneously decreasing the chances of food contamination.

-

Blade Care: A sharp blade ensures both safe food cutting as well as precise outcomes during slicing. Regular inspection of the blade should be performed to check for damage or signs of wear while the Hobart slicer sharpener maintains blade edge quality. Replace the blade immediately when it shows signs of dullness or chipping because it will cause uneven cuts.

-

Lubricate Moving Parts: Regular lubrication of moving parts and the carriage helps maintain smooth operation of the machine. A food-safe lubricant should be applied to rails and bearings to reduce friction and minimize wear.

-

Examine the motor system and electrical wiring components: Regular checks of both the motor components and electrical wiring need to be performed to identify overheating or signs of wear. Check the power cord for complete integrity and inspect it for any signs of fraying or damage.

-

Regular Inspections: Perform scheduled inspections to verify the condition of loose screws and misaligned parts and damaged components. Early detection and resolution of small issues protects the system from developing major operational failures.

The combination of proper preventative cleaning and regular maintenance practices will improve Hobart slicer parts performance and extend their operational lifespan while guaranteeing less equipment breakdowns.

For more on maintaining commercial kitchen equipment, check out our Commercial Blender Buying Guide: Types, Uses, Features & Benefits, which also covers upkeep tips for other appliances.

Conclusion: Keep Your Hobart Slicer Running Smoothly

Your Hobart slicer requires regular maintenance to reach its peak operational state while delivering uniform high-quality cuts in every use. Regular inspections and cleaning of the slicer combined with prompt attention to Hobart slicer parts dullness and motor issues and carriage slowness will help extend the equipment's lifespan while avoiding expensive maintenance costs. The combination of cleaning your Hobart slicer daily along with regular lubrication and consistent inspections in your maintenance process will prevent multiple typical issues from occurring.

The lifespan of your slicer depends on prompt replacement of blade and motor components that become worn out. Regular care through servicing results in better operational flow and creates safer kitchen conditions. Staying active with Hobart slicer maintenance practice ensures both efficient operating capability and reduced business disruptions while guaranteeing top-quality outcomes for your operation.

FAQs

Where is the reset button on a Hobart slicer?

The reset button on a Hobart slicer is usually found close to the motor or at the back of the machine, usually labeled with a red button. Check the user manual for the specific location, as it can differ based on the model.

How often should a meat slicer be cleaned minimum?

The meat slicer must be cleaned daily after use to avoid the accumulation of food particles, grease, and bacteria. In cases of heavy use, cleaning after each shift is advisable to provide hygienic operation.

What is the warning on the meat slicer?

The meat slicer warning typically advises against possible risks, including exposed blades, improper use, or electrical faults. Ensure the slicer is maintained in good condition and use caution to prevent injury or malfunction.

What are the settings on a meat slicer?

The controls on a meat slicer would generally consist of the thickness control to set the thickness of the slices, and blade speed controls. Most slicers also incorporate safety controls to ensure that the slicer is not turned on while in an unattended condition.