How to Troubleshoot a Commercial Oven Thermostat Symptoms, Causes, and Solutions

A commercial oven thermostat is essential for maintaining accurate temperatures and consistent cooking in any professional kitchen. When it malfunctions, it can cause uneven cooking, longer cooking times, or even overheating, which can disrupt kitchen operations and compromise food quality. Identifying thermostat issues early helps prevent costly downtime and keeps your kitchen running efficiently.

This guide will walk you through the common symptoms of a faulty commercial oven thermostat, explain the possible causes, and provide practical solutions to fix these problems. Whether you’re a restaurant owner, kitchen manager, or maintenance professional, understanding how to troubleshoot your oven thermostat ensures safe, reliable, and high-quality cooking results every time.

Common Symptoms of a Faulty Commercial Oven Thermostat

The thermostat in a commercial oven regulates the temperature to ensure even cooking. When it starts failing, your oven may show clear warning signs.

-

Oven Stuck at One Temperature: The oven heats only too high or too low, ignoring the set temperature.

-

Unresponsive Temperature Adjustments: Changing the temperature has little to no effect on the oven’s heat output.

-

Hot Spots or Cold Zones: Some areas inside the oven cook faster or slower than others, causing uneven results.

-

Strange Noises During Operation: Clicking, buzzing, or humming sounds occur as the thermostat struggles to regulate heat.

-

Prolonged Cooking Times: Dishes take longer than usual to cook, even at the correct settings.

-

Unexpected Overheating or Shutdowns: The oven may overheat or turn off unexpectedly while running.

Looking to troubleshoot or replace your commercial oven parts? PartsFe has you covered with high-quality oven replacement parts. From thermostats to heating elements, sensors, and other essential components from top brands like Hobart, Cecilware, and Southbend, we ensure your oven maintains precise temperature control and reliable performance in any busy kitchen.

Understanding the Root Causes Behind Thermostat Failures

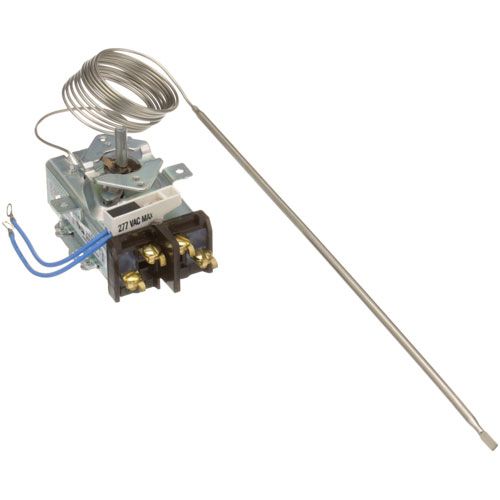

A commercial oven thermostat can fail in ways that affect temperature sensing and control, making oven thermostat troubleshooting essential for accurate diagnosis and repairs. This process ensures consistent cooking and safe kitchen operations.

Thermostat Control Range Failure

The thermostat regulates heat at specific settings but becomes ineffective at higher or lower temperature ranges.

Root Cause: Partial internal component failure within the thermostat limits its ability to regulate across the full temperature range.

Solution: Test the thermostat by adjusting settings from low to high while monitoring temperature response. Replace the thermostat if any portion of the control range remains unresponsive.

Thermostat Not Sensing Temperature Correctly

The thermostat misreads the oven’s internal temperature, leading to incorrect heat regulation.

Root Cause: A damaged or worn temperature sensor inside the thermostat loses accuracy over time.

Solution: Test the thermostat sensor using a calibrated thermometer to confirm inaccurate readings. Replace the thermostat if the sensor cannot be repaired or recalibrated.

Thermostat Fails to Send Heat Signals

The thermostat does not signal the heating element to turn on or off properly.

Root Cause: Internal electrical contacts inside the thermostat become worn, burnt, or stuck.

Solution: Inspect the thermostat contacts for signs of damage or corrosion. Replace the thermostat to restore proper communication with heating components.

Thermostat Calibration Drift

The thermostat gradually loses accuracy, causing temperature differences during cooking.

Root Cause: Prolonged exposure to high heat causes calibration drift within the thermostat mechanism.

Solution: Verify temperature accuracy using an external thermometer. Recalibrate the thermostat if adjustable or replace it when recalibration is not possible.

Thermostat Control Knob or Dial Failure

Turning the thermostat dial does not change temperature settings.

Root Cause: The internal shaft or control linkage inside the thermostat becomes loose or broken.

Solution: Inspect the thermostat knob and shaft for physical damage. Replace the thermostat if the internal linkage is compromised.

Explore common oven light bulb issues and how to fix them to ensure your oven stays bright and fully functional.

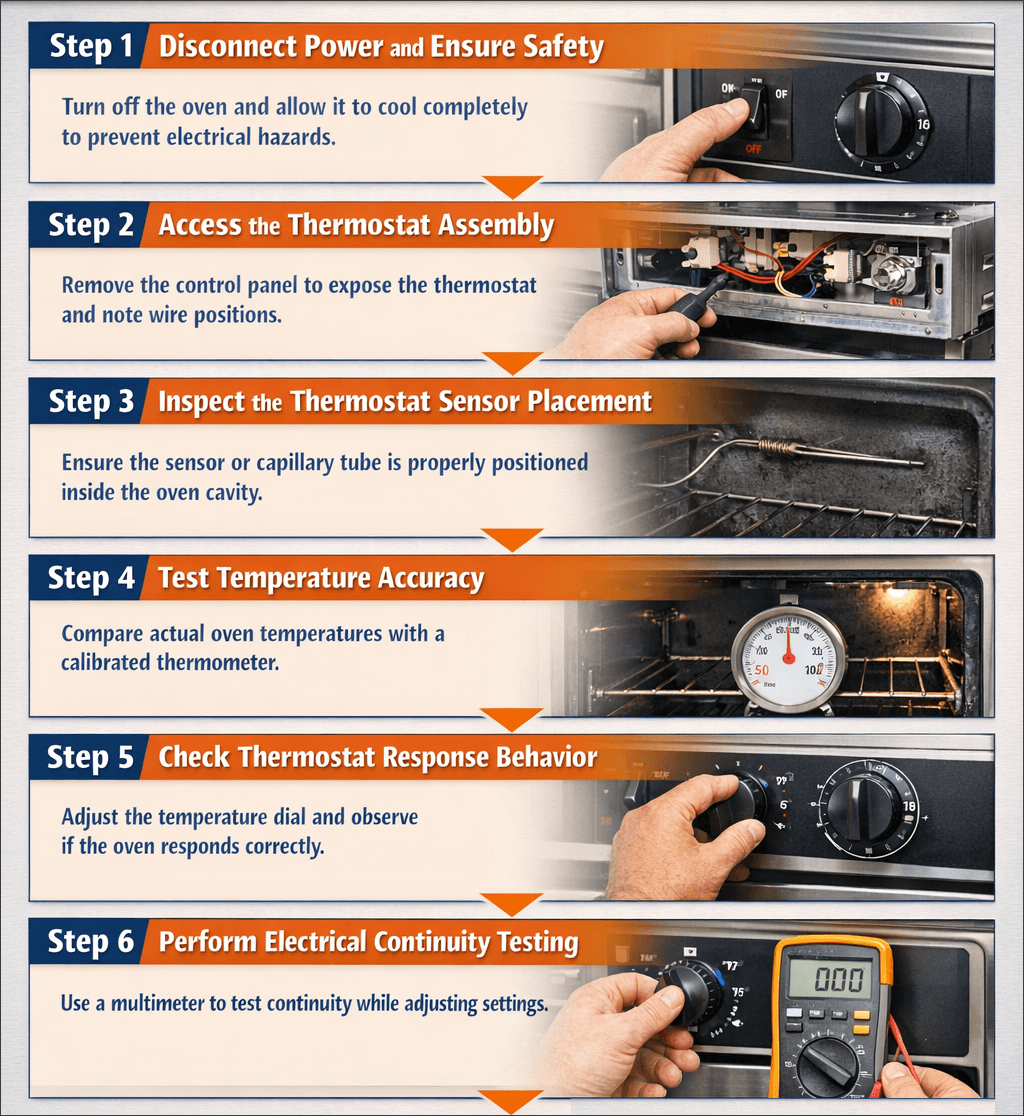

Step-by-Step Process to Troubleshoot and Test the Oven Thermostat

Troubleshooting a commercial oven thermostat requires a careful, methodical approach to avoid misdiagnosis. Following a structured process helps confirm whether the thermostat is truly at fault before replacement.

Tools You’ll need:

-

A multimeter to test electrical continuity

-

Screwdrivers and pliers

-

Manufacturer’s oven manual (for specific thermostat location and specifications)

-

Temperature probe or oven thermometer

When to Repair Vs Replace the Oven Thermostat

Determining whether to repair or replace a commercial oven thermostat depends on the specific fault and its impact on temperature control. Choosing correctly prevents cooking errors and ensures kitchen safety.

|

Issue |

When to Repair |

When to Replace |

|

Inconsistent temperature spikes |

Spikes are minor and caused by calibration errors |

Temperature fluctuates widely despite recalibration |

|

Slow temperature response |

Sensor responds late but readings remain accurate |

Temperature delay affects cooking consistency |

|

Broken or bent capillary tube |

Damage is not repairable and affects temperature sensing |

Any visible damage to the capillary tube |

|

Erratic on/off cycling |

Cycling is caused by loose wiring or mounting |

Cycling continues after wiring and connections are checked |

|

Loose mounting or wiring |

Connections can be tightened or repositioned |

Wiring is burnt, brittle, or terminals are damaged |

|

Intermittent power to heating element |

Power loss is traced to external wiring or connectors |

Thermostat contacts fail internally |

|

Minor drift in high or low settings |

Temperature can be corrected through recalibration |

Drift returns repeatedly after adjustment |

|

Oven stuck at extreme temperatures |

Regulation failure cannot be corrected through repair |

Oven overheats or fails to heat regardless of settings |

|

Frequent false error readings |

Errors are caused by sensor alignment or loose wiring |

Errors continue due to internal electronic faults |

Check out how to replace a thermostat in an oven and learn about oven thermostat replacement cost to maintain accurate temperature control and efficient cooking.

Conclusion: Ensuring Accurate Temperature Control for Reliable Commercial Oven Performance

A well-functioning thermostat ensures even heating, prevents equipment damage, and supports safe kitchen operations. Learning how to troubleshoot oven thermostat issues through regular inspection and timely repairs reduces downtime and extends the oven’s lifespan. Prioritizing thermostat care helps kitchen managers maintain efficiency and food quality in busy commercial environments.

Key Takeaways:

-

Regularly monitor your commercial oven thermostat to prevent cooking inconsistencies.

-

Identify and troubleshoot failures early to avoid prolonged cooking times and downtime.

-

Repair minor issues or replace faulty thermostats based on severity and component condition.

-

Proper maintenance and testing extend the lifespan of your commercial oven and ensure safe operation.

-

Keep a log of thermostat performance and repairs to track recurring issues.

-

Train kitchen staff to recognize early warning signs of thermostat malfunction.

-

Use high-quality replacement parts to ensure reliable and long-lasting performance.

By monitoring thermostat performance and addressing issues promptly, commercial kitchens can ensure reliable temperature control. Repair or replace faulty components as needed to maintain consistent cooking results. Following these practices helps prevent disruptions and keeps ovens running safely and efficiently.

FAQs

Why is my commercial oven not holding temperature?

This usually happens due to a faulty thermostat, heating element, or temperature sensor. Poor door seals or electrical issues can also cause heat loss.

How do I know if my oven thermal fuse is blown?

If the oven won’t heat at all or suddenly shuts off, the thermal fuse may be blown. Testing it with a multimeter for continuity can confirm the issue.

Why won't my oven reach my temperature setting?

A worn heating element or malfunctioning control board may prevent proper heating. Calibration issues or power supply problems can also affect temperature accuracy.