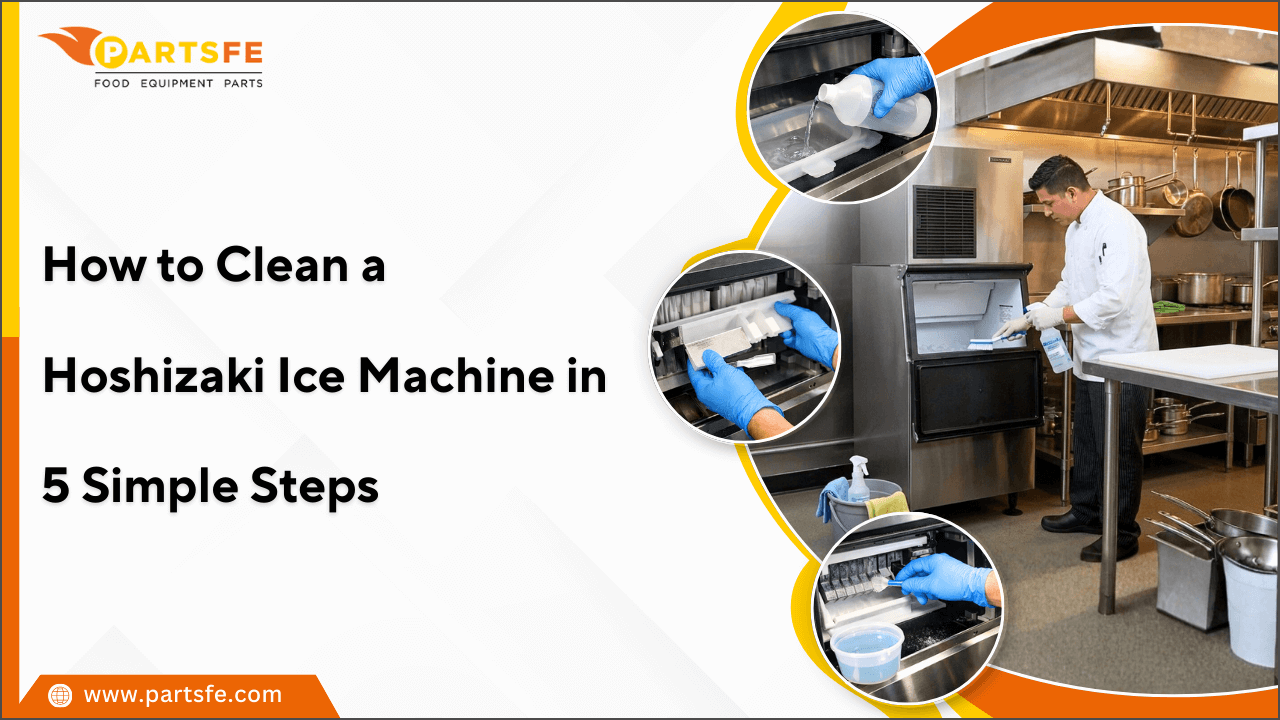

How to Clean a Hoshizaki Ice Machine in 5 Simple Steps

Hoshizaki ice machines are trusted for producing high-quality ice, but regular cleaning is essential to keep them running efficiently. Over time, mineral deposits, mold, and bacteria can accumulate, affecting both the taste of your ice and the machine’s performance. Neglecting maintenance can lead to costly repairs and reduced lifespan.

Hoshizaki ice machine parts reduce mineral buildup and mold growth, helping your machine operate efficiently and ensuring your ice stays fresh, safe, and great-tasting. This guide will walk you through 5 simple steps to clean your Hoshizaki ice machine parts safely and effectively. Whether you run a busy restaurant, café, or simply want hygienic ice at home, these steps make the process quick, easy, and stress-free.

Why Cleaning a Hoshizaki Ice Machine Matters

Proper Hoshizaki ice machine cleaning is crucial for producing safe, high-quality ice while protecting the machine’s performance. Regular cleaning prevents scale buildup, microbial growth, and hidden wear that can silently reduce efficiency. By prioritizing cleaning a Hoshizaki ice machine, operators ensure reliable operation, energy savings, and longer equipment lifespan.

Here’s Why Cleaning Matters In Ways You Might Not Know:

-

Hidden Ice Contaminants: Tiny biofilms can form inside water lines and evaporators, invisible to the naked eye, subtly altering ice quality over time.

-

Sensor Malfunctions: Mineral buildup can interfere with ice level and temperature sensors, causing overproduction or machine shutdowns.

-

Cooling Coil Stress: Dirt and scale on coils reduce heat transfer efficiency, making compressors work harder and shortening their lifespan.

-

Flavor Absorption: Ice can pick up odors from old deposits in tanks or lines, subtly changing the taste of beverages.

-

Microbial Creep: Even trace amounts of mold can colonize surrounding areas, like drip trays or condensers, eventually spreading beyond the machine.

Cleaning your Hoshizaki ice machine is more than hygiene; it preserves performance, protects flavor integrity, and prevents hidden mechanical issues.

Looking to keep your commercial kitchen’s ice production running flawlessly? Order parts for restaurant equipment from PartsFe, including evaporator plates, water filters, ice baskets, sensors, and water distribution tubing for Hoshizaki ice machines. Whether you’re replacing worn components or upgrading critical parts, our reliable solutions help maintain efficiency, hygiene, and consistent ice quality, ensuring your kitchen stays ready for peak service. Fast shipping is available to get your equipment back in top shape without delay.

Tools, Cleaning Solutions, and Safety Precautions You Need Before You Start

Cleaning a Hoshizaki ice machine is more than wiping surfaces; it's about reaching hidden areas, protecting sensors, and maintaining optimal performance. Using a proper Hoshizaki ice machine cleaner along with the right tools makes the process safer, faster, and far more effective.

Essential Tools:

-

Flexible Microfiber Detailing Brushes: Reach tight corners, water nozzles, and behind evaporator plates.

-

Non-Metallic Scraper: Gently removes stubborn scale or slime from plastic parts.

-

Insulated Bucket or Pouring Jug: Prevents temperature shocks to plastic ice bins during rinsing.

-

Small LED Inspection Light: Helps spot hidden mold, slime, or mineral buildup.

-

Precision Syringe or Turkey Baster: Flushing cleaning solution into narrow water lines or tubes.

Cleaning Solutions:

-

Citric Acid-Based Descaler: Safely removes scale without harming sensors or coils.

-

Enzymatic Sanitizer: Breaks down biofilms and microbial layers in water lines.

-

Filtered Water for Rinsing: Reduces mineral deposits and preserves ice clarity.

-

Vinegar-Water Mix: Gently removes light lime buildup in hard-to-reach spots.

Safety Precautions:

-

Turn off the machine and unplug it, tagging it “Under Maintenance” to prevent accidental startup.

-

Put on gloves and safety goggles to avoid contact with cleaning chemicals and sharp edges.

-

Avoid direct sprays on sensors; use a syringe, turkey baster, or small brush for controlled application.

-

Inspect bends, drains, and tubing for slime or buildup, handling carefully to prevent slips or accidental contact.

-

Only use approved cleaning solutions and never mix acids with sanitizers, rinsing thoroughly after each step.

-

Use lukewarm water for rinsing plastic parts to prevent cracking or warping.

-

Ensure floors are dry or use non-slip mats, and ventilate the area to avoid inhaling fumes.

-

Inspect all cleaned parts and ensure no tools or residues remain before reconnecting power.

Using these specialized tools and targeted Hoshizaki ice machine cleaning solutions ensures deep cleaning, protects sensitive components, and maintains crystal-clear ice quality.

Learn how to install your ice maker machine and ensure proper water, drainage, and electrical connections for optimal performance.

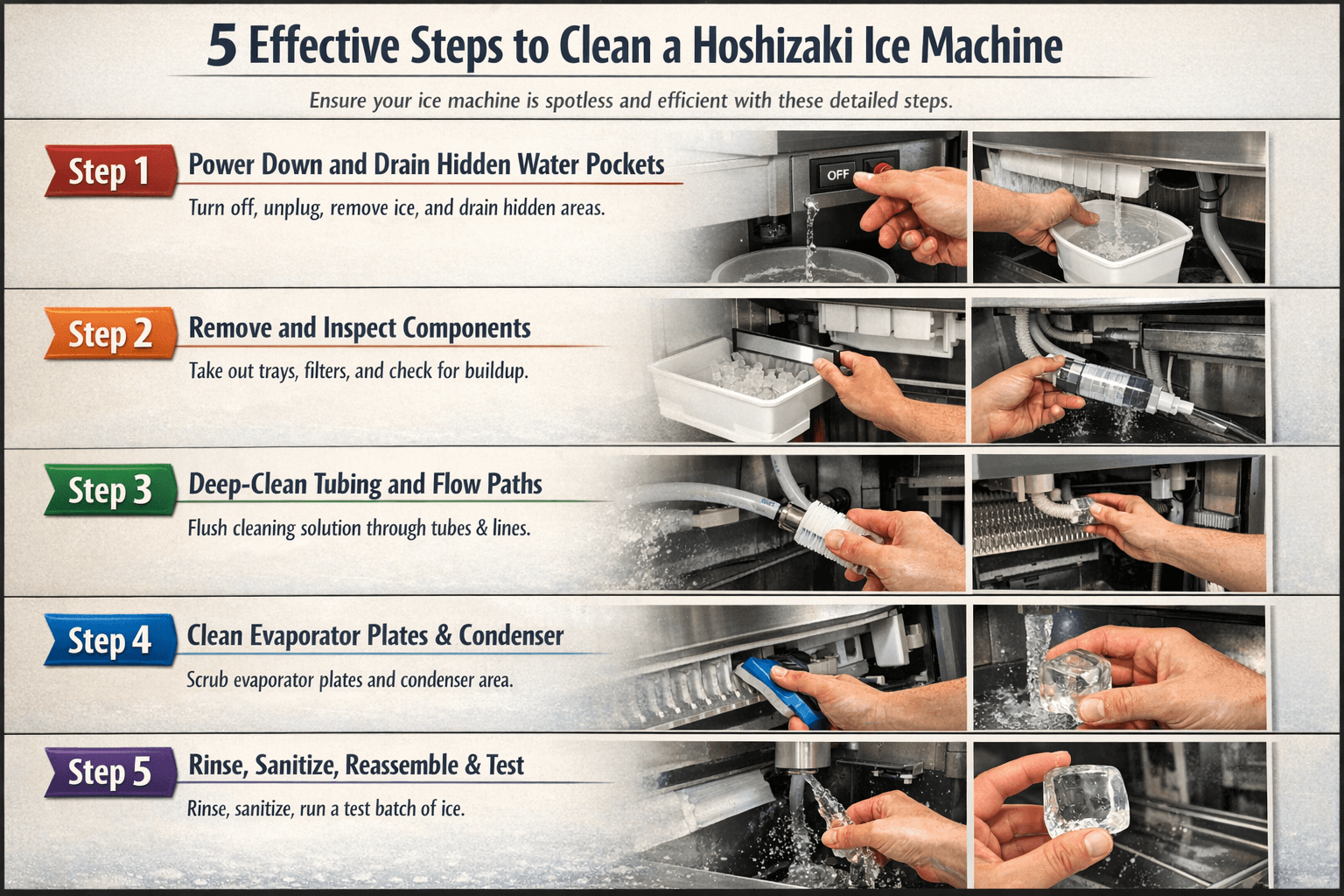

5 Effective Steps to Clean a Hoshizaki Ice Machine

Cleaning a Hoshizaki ice machine isn’t just about wiping surfaces; it's about targeting hidden buildup, protecting sensors, and ensuring crystal-clear ice. These five steps go beyond the usual guide:

Post-Cleaning Checks:

-

Check the Ice Bin Drain Path: Scrub bends and low points in the drain line where biofilm quietly builds up.

-

Rotate Ice Baskets During Cleaning: Twist baskets slightly while washing to loosen scales hidden beneath edges.

-

Pay Attention to Sensor Housings: Gently wipe sensors to remove mineral residue that can affect accuracy.

-

Inspect Condenser Dust Traps: Clean dust from condenser fins monthly to maintain cooling efficiency.

-

Use a Color-Changing Sanitizer Test Strip: Confirm sanitizer reached all tubing and bin surfaces.

-

Flush Ice Maker Lines with Warm Filtered Water First: Pre-flushing softens buildup and improves cleaner effectiveness.

-

Keep a Cleaning Log: Document cleaned components each cycle to avoid missed areas over time.

How Often To Clean Hoshizaki Ice Machine: Clean your ice machine every six months to maintain clear, fresh, and safe ice, and ensure optimal performance by using the Hoshizaki ice machine filter for removing sediment, reducing scale, improving flavor, and protecting components along with approved cleaners and replacing worn parts to keep your system efficient and long-lasting.

|

Disclaimer: This guidance is for routine maintenance purposes only and does not replace professional service. Always follow Hoshizaki’s official instructions for cleaning and part replacement. If uncertain, hire a certified technician to avoid injury or machine damage. |

Common Mistakes to Avoid While Cleaning a Hoshizaki Ice Machine

In commercial kitchens, ice machines operate nonstop and are subject to strict hygiene standards. Cleaning errors can lead to health code violations, equipment failure, and disrupted service.

|

Common Cleaning Mistake |

Impact in Commercial Kitchens |

Correct Cleaning Practice |

|

Cleaning without shutting off the machine |

Can damage sensors, motors, or internal components. |

Always power down and unplug before starting cleaning. |

|

Using non-approved cleaning chemicals |

Harsh cleaners may corrode parts or contaminate ice. |

Use only Hoshizaki-approved, food-safe cleaners. |

|

Overlooking removable parts |

Ice baskets, troughs, and filters may still harbor bacteria. |

Remove and clean all detachable components thoroughly. |

|

Ignoring tubing and water lines |

Biofilm and scale buildup persists in hidden channels. |

Flush and clean all internal tubing and manifolds. |

|

Neglecting sensors and probes |

Mineral deposits can cause false readings or errors. |

Carefully wipe and inspect water-level and temperature sensors. |

|

Using abrasive tools |

Scratches create breeding grounds for bacteria and scale. |

Use soft brushes, microfiber cloths, or silicone scrubbers. |

|

Rinsing improperly |

Residual cleaner or minerals may affect ice quality. |

Rinse all surfaces and tubing with warm, filtered water. |

|

Not sanitizing after cleaning |

Microbes remain despite visible cleanliness. |

Apply food-safe sanitizer and allow proper dwell time. |

|

Reassembling while parts are wet |

Moisture encourages mold growth and corrosion. |

Air-dry all components before reassembly. |

|

Skipping cleaning documentation |

Compliance and quality checks can be compromised. |

Keep a log of cleaning dates, methods, and inspections. |

Caution: Before cleaning, always cut power to the ice machine and avoid direct contact with sharp edges or moving parts. Use only manufacturer-approved cleaners to prevent damage. Improper handling can lead to electrical hazards or component failure.

Find solutions to common water valve issues in commercial ice machines, including leaks, blockages, and flow problems.

Conclusion: Best Practices to Keep Your Hoshizaki Ice Machine Clean

Beyond preventing scale buildup and microbial growth, proper cleaning and maintenance are reshaping how operators approach ice production, workflow, and equipment longevity. These practices enable kitchens to maintain consistent ice quality, optimize energy use, and minimize downtime in ways previously impossible with neglected or irregular maintenance.

Key Takeaways

-

Perform deep cleaning that targets hidden water channels, seams, and under gaskets.

-

Monitor water hardness and flow daily, and consider inline filtration or softening even for minor fluctuations.

-

Keep airflow pathways, vents, and condenser coils free of dust and grease to maintain consistent cooling.

-

Inspect seals, gaskets, and internal fittings monthly to prevent hidden leaks and contamination.

-

Rotate ice production cycles and bin inspections to detect operational

blind spots early.

|

Summary: Regular inspections and proactive maintenance, to prevent poor ice quality, equipment wear, operational disruptions, and potential health risks, ensure consistent ice machine parts for high-quality ice and extend equipment lifespan, supporting efficient, safe, and reliable ice production while reducing stress and downtime |

FAQs

How to clean a Hoshizaki ice machine Model KM-151BAH:

Turn off the machine, drain all water, and remove ice. Clean the bin, evaporator, and internal surfaces with a Hoshizaki-approved cleaner, rinse thoroughly, and sanitize before restarting.

How to clean the filtration system on a Hoshizaki ice machine:

Turn off the water supply, remove the filter, and rinse it under clean water or replace if needed. Reinstall, flush the system with water, and resume normal operation.

How do I reduce VOCs in my Hoshizaki ice machine?

Use a clean, food-grade water source, regularly replace the Hoshizaki ice machine filter, and perform routine cleaning to prevent chemical or odor buildup in ice.