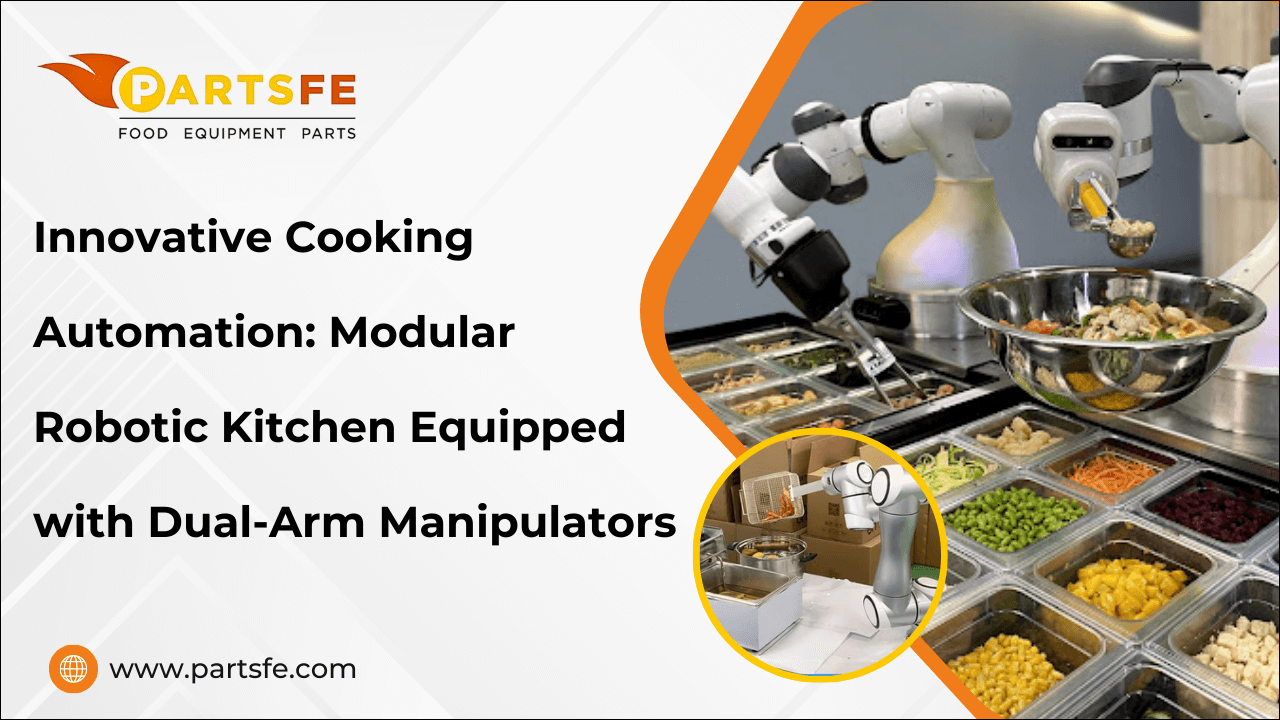

Innovative Cooking Automation: Modular Robotic Kitchen Equipped with Dual-Arm Manipulators

Innovative cooking automation is revolutionizing the culinary world, and the Modular Robotic Kitchen equipped with dual-arm manipulators stands at the forefront of this transformation. This advanced system integrates modular components with highly dexterous robotic arms, enabling precise, efficient, and versatile food preparation. Designed to mimic human chefs’ complex motions, the dual-arm manipulators can handle various cooking tasks simultaneously, from chopping and stirring to plating. The modular design allows easy customization and scalability, making it adaptable for diverse kitchen environments, from home use to large-scale commercial operations. By combining cutting-edge robotics, automation, and smart control, this innovation promises to enhance productivity, consistency, and hygiene in cooking, ultimately reshaping how meals are prepared and elevating the future of automated culinary technology.

| Table of Contents: Understanding the Role of Dual-Arm Manipulation Technology in Modular Robotic Kitchens Essential Components of a Modular Robotic Kitchen System How Dual-Arm Robots Enhance Cooking Efficiency Key Benefits of Robotic Kitchens in Commercial Foodservice Settings Applications of Modular Kitchens with Dual-Arm Manipulators in Cooking Automation Final Thoughts |

Understanding the Role of Dual-Arm Manipulation Technology in Modular Robotic Kitchens

Dual-arm manipulation technology is a cornerstone of modern modular robotic kitchens, enabling robots to perform complex cooking tasks with precision and efficiency. This technology replicates the coordination and dexterity of human arms, allowing robotic systems to handle multiple actions simultaneously. Here’s how dual-arm manipulation technology plays a vital role:

Enhanced Dexterity and Coordination:

-

Dual arms can work together seamlessly, performing tasks such as chopping with one arm while stirring with the other.

-

This coordination mimics human chefs’ natural motions, making robotic cooking more versatile.

Multitasking and Efficiency:

-

Robots equipped with dual arms can execute multiple cooking processes simultaneously, significantly speeding up meal preparation.

-

This capability improves kitchen throughput and reduces waiting times.

Precision and Consistency:

-

Dual-arm manipulators deliver precise movements, ensuring consistent cutting, mixing, and plating every time.

-

This reduces human error and guarantees high-quality dishes.

Complex Task Handling:

-

The technology allows robots to manage intricate cooking steps that require fine motor skills, such as folding dough or flipping ingredients.

-

It expands the range of recipes that can be automated.

Safety and Hygiene:

-

Automated dual-arm systems minimize human contact with food, reducing contamination risks.

-

Their design incorporates safety protocols to operate safely alongside humans.

Integration with Modular Systems:

-

Dual-arm manipulators fit seamlessly into modular kitchen setups, allowing flexible configuration and easy upgrades.

-

This adaptability supports diverse cooking environments, from home kitchens to commercial spaces.

By enabling robots to perform complex, coordinated actions with speed and accuracy, dual-arm manipulation technology is transforming modular robotic kitchens into powerful tools for automated culinary innovation.

Essential Components of a Modular Robotic Kitchen System

A modular robotic kitchen combines various specialized components designed to optimize cooking automation. These parts work in harmony to create a versatile, efficient, and user-friendly system:

Robotic Dual-Arm Manipulators:

-

Advanced robotic arms capable of mimicking human hand coordination for diverse culinary tasks.

-

Designed for adaptability, allowing easy reprogramming for different recipes and techniques.

Interchangeable Cooking Modules:

-

Modular units such as induction cooktops, steamers, and robotic dispensers that can be swapped or upgraded as needed.

-

Facilitates rapid adaptation to new cooking methods or menu changes without replacing the entire system.

AI-Powered Control Hub:

-

An intelligent control center that learns and optimizes cooking processes over time.

-

Uses machine learning to improve recipe execution and reduce waste.

Integrated Ingredient Handling System:

-

Automated storage, retrieval, and dispensing mechanisms to manage ingredients efficiently.

-

Ensures precise portioning and freshness control.

Environmental Monitoring Sensors:

-

Sensors track temperature, humidity, and air quality to maintain ideal cooking and hygiene conditions.

-

Helps prevent equipment overheating and ensures food safety compliance.

User Interaction Platform:

-

Customized interfaces, including mobile apps and voice assistants, provide real-time status updates and remote control options.

-

Supports user feedback to refine cooking preferences.

Maintenance and Diagnostics Module:

-

Built-in self-check and alert systems to predict maintenance needs and minimize downtime.

-

Simplifies troubleshooting and prolongs equipment lifespan.

This combination of components empowers modular robotic kitchens to deliver high-quality, consistent meals while allowing flexibility and ease of use in various culinary environments.

How Dual-Arm Robots Enhance Cooking Efficiency

Dual-arm robots enhance cooking efficiency by mimicking coordinated human arm movements. They perform complex tasks with dexterity, speed, and precision, transforming the cooking process.

-

Simultaneous Task Execution: With two arms, robots can handle multiple tasks at once, such as chopping vegetables with one arm while stirring a pot with the other, reducing overall cooking time.

-

Improved Dexterity: The dual-arm setup allows robots to perform intricate movements like flipping pancakes or kneading dough, which single-arm systems struggle to achieve.

-

Enhanced Tool Handling: Robots can switch between different kitchen tools seamlessly, using one arm to hold ingredients and the other to operate utensils, mimicking human multitasking.

-

Greater Precision: Coordinated arm movements enable precise control over cooking techniques, ensuring consistent results, such as evenly flipping food or delicately plating dishes.

-

Reduced Human Error: Automation of complex, repetitive tasks minimizes mistakes related to timing, ingredient handling, and temperature control.

-

Faster Meal Preparation: Parallel processing of cooking steps speeds up meal preparation, increasing throughput in commercial kitchens and convenience in home environments.

In essence, dual-arm robots bring human-like efficiency and skill to automated kitchens, enhancing productivity and food quality.

Key Benefits of Robotic Kitchens in Commercial Foodservice Settings

Robotic kitchens equipped with dual-arm manipulation are rapidly reshaping commercial foodservice, offering tangible advantages that extend beyond automation hype. Here are some unique, real-world benefits these technologies bring to the industry:

-

Operational Consistency Across Locations: For multi-unit restaurant chains, robotic kitchens ensure every location produces dishes with identical taste and presentation, strengthening brand reputation and customer trust.

-

Optimized Kitchen Layouts: Modular robotic systems reduce the need for large kitchen staff and equipment, enabling restaurants to downsize kitchen space, invest in customer seating, or expand delivery prep areas.

-

Enhanced Food Safety Protocols: Automated handling minimizes human error in hygiene compliance, crucial for meeting stringent food safety regulations and avoiding costly health inspections or recalls.

-

Data-Driven Menu Innovation: Robotic kitchens collect detailed cooking data that chefs and managers use to refine recipes, experiment with new dishes, and tailor menus based on customer preferences and operational efficiency.

-

Cost Savings on Utilities: Robots precisely control cooking temperatures and times, leading to measurable reductions in energy consumption compared to manual cooking, contributing to lower utility bills.

-

Faster Training and Onboarding: New hires require less time to become productive, as robots handle complex cooking steps and standardize processes, reducing training costs and errors.

-

Scalable Solutions for Pop-Up and Ghost Kitchens: The portability and modularity of robotic kitchens allow businesses to quickly set up efficient cooking operations for temporary or delivery-only concepts without large capital investment.

These benefits demonstrate that robotic kitchens are not just futuristic novelties but practical solutions delivering measurable improvements in efficiency, safety, and profitability for commercial foodservice operators.

Check out this article on the future of restaurant equipment: emerging trends to watch to explore how automation, smart technology, and sustainable designs are reshaping the culinary industry.

Applications of Modular Kitchens with Dual-Arm Manipulators in Cooking Automation

Modular kitchens integrated with dual-arm manipulators are pushing the boundaries of culinary automation by enabling novel and specialized applications that go beyond traditional cooking tasks:

-

Adaptive Recipe Learning: Dual-arm systems use AI to learn new recipes by observing chefs, allowing kitchens to rapidly adapt without reprogramming from scratch.

-

Simultaneous Multi-Dish Preparation: The manipulators coordinate to prepare multiple dishes at once, optimizing kitchen throughput during high-demand periods.

-

Precision Ingredient Pairing: Robots can combine ingredients at a molecular level, supporting advanced culinary techniques like flavor layering and molecular gastronomy.

-

Dynamic Workspace Reconfiguration: Modular setups enable the kitchen layout to adjust in real-time, with dual-arm robots adapting their movements based on available workspace and task priorities.

-

Waste Sorting and Recycling: Beyond cooking, dual-arm robots can handle waste segregation automatically, ensuring sustainable kitchen operations.

-

Assistive Cooking for Disabled Users: These systems can be tailored to help individuals with mobility challenges prepare meals independently.

-

Remote Operation and Monitoring: Dual-arm robotic kitchens can be controlled remotely, allowing centralized kitchens to serve multiple locations or operate in hazardous environments.

-

Real-Time Sensory Feedback Integration: Manipulators can respond to tactile and visual sensors to adjust grip strength or cooking pressure, thereby improving the handling of delicate foods.

This diverse range of applications highlights how modular kitchens with dual-arm manipulators are not only automating cooking but also innovating the entire culinary experience.

Explore this article on how automation found a new way to improve your restaurant’s heart to find innovative technologies that enhance kitchen efficiency, streamline operations, and elevate the dining experience.

Final Thoughts

The modular robotic kitchen with dual-arm manipulators represents a significant leap forward in cooking automation, combining flexibility, precision, and efficiency. By integrating advanced robotics into culinary processes, this innovation not only enhances consistency and speed but also reduces labor costs and human error. As technology continues to evolve, such systems have the potential to revolutionize commercial kitchens, making high-quality cooking more accessible. Ultimately, this approach paves the way for smarter, more adaptable kitchens that can meet the growing demand for automation without sacrificing creativity or quality.

Need equipment parts to power your smart kitchen setup? PartsFe offers high-quality fryer parts, griddle & grill parts, and ice machine parts from leading brands like Allpoints, Johnson Controls, and Panasonic. Keep your modular robotic kitchen running smoothly with precision-engineered solutions.

FAQs

How do dual-arm manipulators improve cooking tasks?

Dual-arm systems enable coordinated actions like chopping, stirring, and multitasking simultaneously, improving efficiency and mimicking human dexterity. Equipped with smart actuators, they can sense force and position, enabling precise and dynamic movements.

What are proprioceptive actuators and why are they used?

Proprioceptive actuators enable the robot to sense and control its own movements and forces, thereby enhancing safety and responsiveness during cooking. This is crucial for delicate, high-speed tasks, such as cutting and mixing.

What are the benefits of using a modular robotic kitchen?

Benefits include consistent food quality, reduced labor costs, improved hygiene, time savings, and the ability to handle multiple tasks simultaneously.