How to Replace and Adjust the Manitowoc Ice Thickness Probe: Tips and Solutions

Maintaining the precise measurement and control of ice thickness is crucial for the efficient operation of Manitowoc ice machines. The ice thickness probe plays a pivotal role in ensuring the consistency and quality of ice production. Over time, factors such as wear, scale buildup, or mechanical issues can impact the reliability of the probe, necessitating replacement and adjustment. This guide will explore step-by-step procedures, best practices, and effective solutions for the replacement and adjustment of the Manitowoc Ice Thickness Probe. By understanding these essential processes, users can proactively manage the performance of their ice machines, troubleshoot potential problems, and ultimately optimize ice production.

|

Table of Contents |

What is the Manitowoc Ice Thickness Probe?

The Manitowoc Ice Thickness Probe is a component in Manitowoc ice machines that measures and monitors the thickness of the ice being produced. It plays a crucial role in ensuring that the ice forms to the desired thickness, contributing to the overall functionality of the ice-making process. The Manitowoc Ice Thickness Probe functions by detecting the depth of the ice as it forms on the evaporator plate. As the ice reaches the desired thickness, the probe sends signals to the machine's control system to initiate the harvesting process, where the ice is released from the evaporator plate. This continuous monitoring of ice thickness helps maintain consistent ice production and quality.

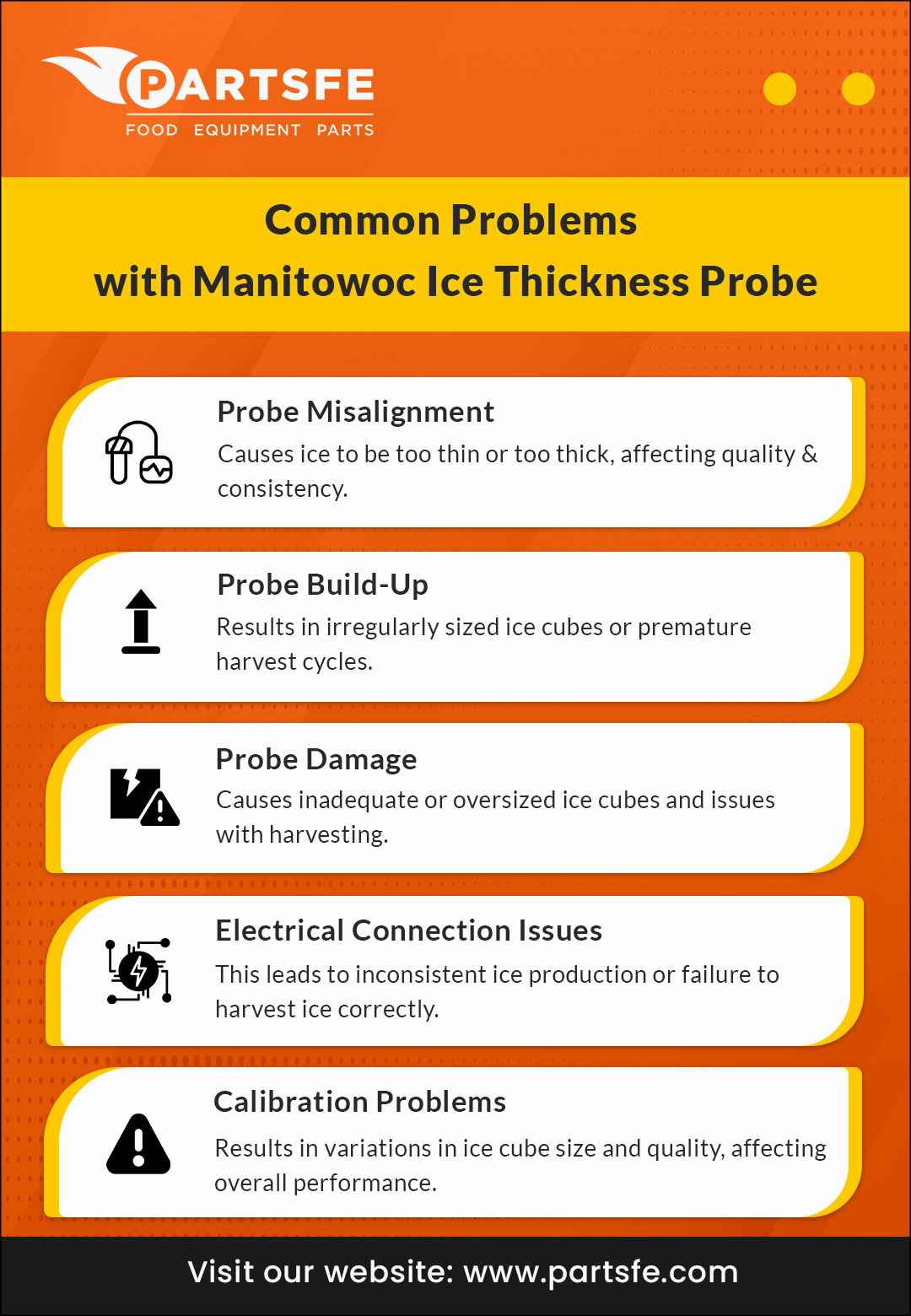

Common Problems with Manitowoc Ice Thickness Probe

Signs of Faulty Manitowoc Ice Thickness Probe

- Inaccurate readings: If the probe consistently provides incorrect thickness readings, leading to issues with ice production.

- Physical damage: Visible damage to the probe, such as broken parts or corrosion, that impairs its functionality.

- Failure to signal: The probe fails to send the appropriate signals to the control system for ice harvesting, resulting in irregular ice formation.

Also, find these 5 Signs You Need To Replace Or Clean Your Ice Machine

How to Replace the Manitowoc Ice Thickness Probe?

- Power down the ice machine before starting any work, ensure the ice machine is powered down and unplugged to prevent electrical hazards.

- Locate the ice thickness probe refer to the Manitowoc ice machine manual to locate the position of the ice thickness probe within the machine. It is essential to have a clear understanding of its location for safe and accurate replacement.

- Remove the old ice thickness probe and carefully detach the old ice thickness probe from its housing using the appropriate tools, following any disassembly instructions provided in the manual. Take note of the wiring connections and any fasteners securing the probe in place.

- Install the new Manitowoc ice thickness probe carefully install the new ice thickness probe in the exact position from which the old probe was removed. Ensure that it is securely fitted and all wiring connections are correctly reattached, following any specific instructions provided in the manual.

- Adjust the probe for accurate readings once the new ice thickness probe is installed, adjust it according to the manufacturer's guidelines to ensure accurate readings. This may involve calibrating the probe to guarantee optimal performance in measuring ice thickness.

How to Test Manitowoc Ice Thickness Probe?

Using an ice thickness tester:

- Ice Thickness Tester or Depth Checker: An ice-thickness tester, often provided by the manufacturer, is a tool used to measure the thickness of ice on the evaporator plate. It typically consists of a probe or sensor that is manually placed on the ice surface to obtain a reading.

Ice thickness measurement:

- Use the Manitowoc ice thickness sensor to measure the thickness of the ice formed on the evaporator plate. Compare the measured thickness to the desired thickness specified by the manufacturer for optimal ice production.

Consistency test:

- Conduct multiple thickness measurements at different locations on the evaporator plate to ensure that the probe consistently provides accurate readings across the entire surface.

Operational test:

- Initiate an ice-making cycle and monitor the probe's performance in signaling the control system to start and stop the ice harvesting process at the appropriate ice thickness.

Troubleshooting Common Issues with Manitowoc Ice Machines

|

Issue |

Troubleshooting Tips |

|

Manitowoc ice machine fault codes |

- Refer to the Manitowoc ice machine manual to identify and interpret specific fault codes. - Each code corresponds to a particular issue, guiding troubleshooting and resolution. |

|

Manitowoc ice machine not harvesting |

- Check the ice thickness probe for accuracy and cleanliness. - Inspect components like the water inlet valve, evaporator plate, and harvest control system for issues preventing ice harvesting. |

|

Manitowoc ice machine bin full error |

- Clear the ice bin of obstructions or excess ice. - Ensure the bin full sensor is clean and functioning correctly. - Inspect the control board and related components if the issue persists. |

|

Manitowoc ice machine ice thickness probe adjustment |

- Follow the Manitowoc ice machine manual for calibrating and adjusting the ice thickness probe. - Proper adjustment ensures accurate ice thickness measurement and efficient ice-making. |

|

Manitowoc ice machine won't turn on |

- Ensure the machine is receiving power and the power switch is in the correct position. - Check electrical connections, fuse, and circuit breaker. - If unresolved, consult a technician. |

Maintenance of Manitowoc Ice Thickness Probe

- Regular cleaning: Periodically clean the ice thickness probe to remove any build-up of scale, debris, or mineral deposits that can affect its accuracy. Use a soft cloth or brush and a mild cleaning solution recommended by the manufacturer.

- Visual inspection: Regularly inspect the ice thickness probe for any signs of damage, such as corrosion, bent components, or loose connections. Address any issues promptly to prevent operational problems.

- Calibration checks: Follow the manufacturer's guidelines for calibrating the ice thickness probe to ensure accurate readings. Regular calibration checks can help maintain the probe's precision in measuring ice thickness.

- Monitoring performance: During ice-making cycles, pay attention to the probe's functionality in signaling the control system for ice harvesting. Note any irregularities in ice thickness or timing to identify potential issues with the probe.

Discover Tips for Keeping Up and Swapping Out Ice Machine Water Pump

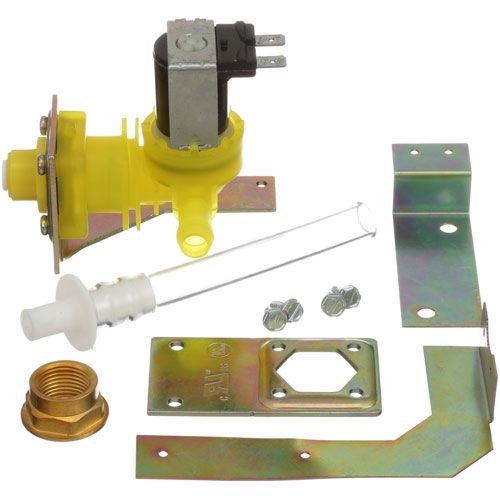

Understanding Manitowoc ice machine problems and adjusting the Ice Thickness Probe is crucial for the consistent and reliable performance of your ice machine. By following the step-by-step instructions and utilizing the provided tips and solutions, you can effectively address issues related to the probe, ensure accurate ice thickness measurements, and maintain optimal ice production. Regular maintenance, proper calibration, and prompt troubleshooting of the ice thickness probe will contribute to the longevity and efficiency of your Manitowoc ice machine. PartsFe offers a wide selection of Ice Machine Parts and accessories such as valves, filters, and pumps at competitive prices. we provide same-day shipping for your convenience.

FAQs

Why is it important to clean the Manitowoc water level probe?

Regular cleaning of the water level probe helps maintain accurate water level detection, preventing malfunctions and ensuring proper ice production.

How often should the Manitowoc ice machine be cleaned?

The Manitowoc ice machine should be cleaned at least every 6 months, or more frequently depending on usage and environmental conditions.

How to clean ice machine in Manitowoc?

Use a mixture of water and a Manitowoc-approved cleaner to clean the bin, evaporator, and other components.

What tools are needed to replace the ice thickness probe?

Commonly, you will need a screwdriver, wrench, and potentially a multimeter for electrical testing.