How to Troubleshoot APW Wyott Food Warmers in Commercial Kitchens

APW food warmers are essential equipment in commercial food warmers, commonly used in restaurants, cafeterias, and catering services to keep food at safe serving temperatures. Over time, these parts, such as heating elements, thermostats, control boards, and fans, can wear out or stop working properly, causing the equipment to underperform or fail. Knowing how to diagnose and repair the APW Wyott warmer is important for reducing downtime and maintaining consistent food quality. This guide will help you identify common issues with American Permanent Ware parts in commercial food warmers and provide clear steps for troubleshooting and repair, enabling technicians and operators to keep their equipment running smoothly and extend its lifespan.

Why APW Wyott Food Warmers Are Essential for Commercial Kitchens

APW Wyott food warmers are fundamental to the proper functioning of commercial kitchens. These components work together to ensure food is kept at safe and consistent temperatures, which is critical in foodservice operations. When any part malfunctions, it can disrupt the warming process, leading to food safety risks and operational inefficiencies. Here’s why APW food warmers are so important:

-

Temperature Control: Thermostats and sensors regulate the heat to maintain safe serving temperatures, preventing food from spoiling or drying out.

-

Heating Efficiency: Heating elements convert electrical energy into heat, providing the necessary warmth to keep food at the desired temperature.

-

Durability: Quality APW food warmer parts are designed to withstand the high-usage demands of commercial kitchens, reducing the frequency of breakdowns.

-

Energy Consumption: Properly functioning parts ensure the food warmer operates efficiently, helping reduce energy waste and operating costs.

-

Safety: Components like control boards and safety switches prevent overheating and electrical hazards, protecting both staff and customers.

-

Consistency: Dependable parts help maintain uniform heat distribution, ensuring every serving is fresh and appetizing.

Looking to fix your commercial food warmer fast and affordably? PartsFe carries essential components like thermostats, heating elements, and power switches. Choose from top-quality brands like APW, Hatco, Wells, and Nemco to keep your unit running efficiently

Common Warning Signs of APW Food Warmer Problems in Commercial Kitchens

Being alert to even subtle issues with the APW food warmer can help prevent bigger failures down the line. Recognizing both common and uncommon signs keeps your food warmers operating smoothly.

-

Intermittent Power Loss: The warmer sometimes loses power unexpectedly, indicating wiring or control board faults.

-

Burnt Smell: A faint burning odor may signal overheating components or electrical issues.

-

Flickering Display: The control panel screen flickers or glitches, hinting at a failing control board.

-

Water or Moisture Inside Unit: Internal components may corrode and short-circuit if there is moisture present.

-

Unresponsive Controls: Buttons or knobs fail to respond, suggesting control panel or wiring problems.

-

Heating Element Clicking: Clicking noises from the heating element might indicate expansion issues or damage.

Identifying Common Problems with APW Food Warmers in Commercial Kitchens

Identifying common APW food warmer issues can help avoid unexpected breakdowns and expensive repairs. Early detection ensures your food warmer runs safely and efficiently.

-

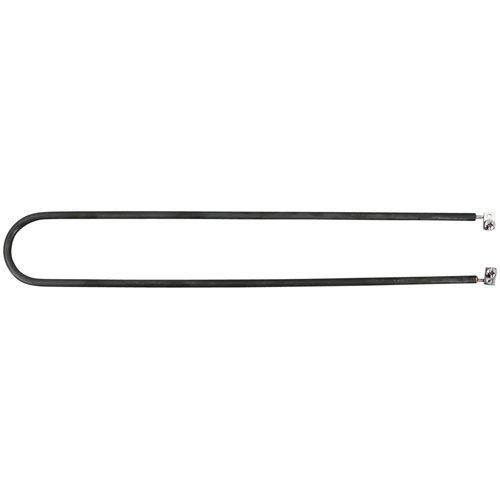

Heating Element Failure: Uneven heating or total heat loss may result from the heating element burning out or developing hot patches.

-

Thermostat Malfunction: Faulty thermostats may give inaccurate temperature readings, leading to improper food warming.

-

Control Board Errors: Damage or failure in the control board can cause erratic operation, unresponsive controls, or unexpected shutdowns.

-

Sensor Problems: Temperature sensors that are broken or misaligned can send wrong data, affecting temperature control.

-

Wiring Issues: Frayed, loose, or burnt wires can cause intermittent power loss, shorts, or even pose a safety hazard.

-

Fan or Motor Failure: Fans that don’t work properly reduce airflow and cause overheating inside the unit..

Regularly inspecting and maintaining these components helps prolong the life of your commercial APW food warmer while ensuring safe and efficient performance.

Check out this article on what is a thermostat, how does it work, and what are the different types? to better understand its role in temperature control systems and how to choose the right one for your needs.

Essential Tools and Safety Precautions for Diagnosing and Repairing APW Food Warmers

Make sure you have the appropriate tools and follow all safety precautions before doing any repairs.

Tools Needed

-

Multimeter for electrical testing

-

Screwdrivers (Phillips and flathead)

-

Nut drivers or socket set

-

Insulated pliers and wire strippers

-

Replacement APW food warmer parts (heating elements, thermostats, switches, control boards)

-

Electrical contact cleaner and a cleaning brush

-

Safety glasses and gloves are examples of personal protective equipment (PPE)

Safety Precautions

-

Unplug Before Repairs: Always unplug the warmer before starting any repairs to avoid electrical shock.

-

Use Insulated Tools: To avoid unintentional electrical contact, use insulated instruments when working.

-

Discharge Capacitors: If the warmer has control boards with capacitors, safely discharge them before handling.

-

Work in a Safe Environment: To lower the chance of mishaps, carry out repairs in a dry, well-lit environment.

-

Observe the manufacturer's instructions: When replacing parts, always follow the manufacturer's recommendations.

-

Seek an Expert: Ask a competent technician for assistance if you have any questions about any step.

Focusing on safety minimizes the chances of injury and equipment damage.

Step-by-Step Process for Diagnosing and Repairing APW Food Warmers Parts

Following a structured process helps ensure accurate diagnosis and effective repair of APW food warmer parts. This step-by-step guide outlines the essential actions to ensure your APW food warmer operates smoothly.

Step 1: Initial Inspection and Unplugging

-

Power Off and Unplug: Always turn off and unplug the unit before starting any inspection.

-

Exterior Inspection: Examine the outside for any obvious damage or loose parts that could compromise functionality.

-

Access Internal Components: Remove panels carefully to expose the internal parts for further inspection.

Step 2: Visual Check of APW Food Warmer Parts

-

Inspect Heating Elements: Look for any burns, corrosion, or obvious damage on heating elements.

-

Check Thermostats and Switches: Examine for discoloration, cracks, or breakage.

-

Examine Wiring: Identify any frayed wires, burn marks, or loose terminal connections.

Step 3: Testing Electrical Components

-

Test Heating Element Continuity: Use a multimeter to check if the heating element has proper continuity.

-

Measure Thermostat Resistance: Verify thermostat readings are within manufacturer specifications.

-

Check Control Board Voltage: Confirm the control board outputs correct voltages at relevant points.

-

Test Thermostatic Switches: Ensure switches operate correctly through resistance or continuity testing.

Step 4: Replace Faulty Parts

-

Remove Damaged Parts: Carefully detach any defective components without causing further damage.

-

Install New Components: Place new APW Wyott warmer parts in the correct orientation, ensuring secure and proper connections.

-

Use Approved Parts: Always use manufacturer-approved replacements for compatibility and safety.

Step 5: Reassemble and Power On

-

Reattach Panels: Secure all access panels back onto the unit properly.

-

Reconnect Power: Plug the warmer back in safely before turning it on.

-

Monitor Startup: Observe the initial power-up and operation for any immediate issues.

Step 6: Functional Testing

-

Set Operating Temperature: Set the warmer to the temperature you want.

-

Check Heat Consistency: Use a thermometer to ensure even heating across the warming surface.

-

Listen and Observe: Note any unusual sounds or erratic cycling that may indicate remaining issues.

Final Checks After Repair to Ensure Proper Function of APW Food Warmers

Performing final checks after repairing the APW food warmer operates safely and efficiently. These steps help catch any issues before returning the unit to service.

-

Visual Inspection: Carefully examine all replaced parts and wiring to confirm secure connections and correct installation without visible damage.

-

Power-On Test: Plug in and turn on the warmer to verify it powers up smoothly, without strange noises or error messages.

-

Temperature Accuracy: Use a calibrated thermometer to check that the warmer reaches and maintains the correct temperature.

-

Heat Distribution: Ensure heat spreads evenly across the warming surface to avoid any cold spots or overheating areas.

-

Control Functionality: Test all controls, including knobs, buttons, and displays, to confirm they respond properly and adjust settings accurately.

-

Monitor Cycling: Watch the heating cycles to make sure the thermostat and control board switch on and off smoothly without rapid cycling.

-

Safety Checks: Check for signs of overheating, unusual smells, or electrical issues during operation to ensure safe use.

-

Final Cleanup: Secure all panels properly and clean the unit to prepare it for safe, hygienic use in food service.

Check out this article on what is a thermocouple: types, uses, and how to install to learn how this essential sensor works and how to use it safely in various applications.

Preventive Maintenance Tips to Avoid APW Food Warmers Issues

Regular maintenance helps prevent the APW food warmer from failing and keeps commercial food warmers running smoothly. Simple, consistent care can save time and repair costs.

-

Regular Cleaning: Clean heating elements, sensors, and internal parts regularly to remove grease, dirt, and corrosion buildup. This prevents damage and ensures efficient operation.

-

Inspect Wiring and Connections: Check wiring for frays, damage, or looseness during routine inspections. Secure all connections to avoid electrical faults and hazards.

-

Test Thermostats and Sensors: Periodically measure thermostat and sensor accuracy with proper tools. Replace any faulty components promptly to maintain temperature control.

-

Check Control Boards: Examine control boards for dust, moisture, or signs of wear and damage. Keeping boards clean helps prevent malfunctions and prolongs their lifespan.

-

Monitor Heating Performance: Verify that the warmer heats evenly and holds the set temperature consistently during use. Detect any fluctuations early to prevent food safety risks.

-

Replace Worn Parts Early: Replace parts as soon as possible rather than waiting for them to fail. Proactive part replacement prevents additional damage and expensive downtime.

-

Follow Manufacturer Guidelines: Follow the manufacturer's recommended maintenance schedules and directions in the manual. This guarantees appropriate maintenance and adherence to the warranty.

-

Schedule Professional Inspections: Arrange for a qualified technician to inspect your equipment annually. Professional checks help identify hidden issues before they escalate.

Conclusion

Troubleshooting and repairing an American Permanent Ware food warmer in commercial kitchens requires attention to detail and a methodical process. Proper maintenance and timely repairs help avoid unexpected failures, ensuring the equipment operates safely and efficiently. By regularly inspecting components, testing electrical parts, and replacing damaged elements with manufacturer-approved parts, you can maintain consistent heating performance and extend the life of your warmer. Ultimately, a proactive approach to diagnosing and fixing APW Wyott warmer protects your investment and supports smooth food service operations.

FAQs

How do I know if the heating element in my APW food warmer is faulty?

Check if the warmer isn’t heating or has cold spots. Use a multimeter to test the element for continuity; no continuity means it’s faulty.

Can I replace APW food warmer parts myself, or should I hire a professional?

Simple repairs like replacing thermostats or heating elements can be DIY with proper safety precautions. For complex electrical issues, it’s best to consult a certified technician.

How often should I perform maintenance on the APW food warmer?

Inspect and clean components every 3-6 months, depending on usage. Regular maintenance helps prevent unexpected failures and extends equipment life.

How do I test if the control board is working properly?

Use a multimeter to check voltage outputs and ensure signals are sent to the heating elements. If there’s no voltage, the control board might need replacement.