Turbo Air Refrigerator Troubleshooting: Here's How to Fix

Turbo Air refrigerators are known for their durability and efficiency, making them a popular choice in both home and commercial kitchens. However, like any appliance, they can face issues like temperature inconsistencies or strange noises. Many of these problems can be resolved with simple troubleshooting. In this guide, we’ll cover common Turbo Air refrigerator issues and provide step-by-step solutions to get your fridge back in working order. Whether you're dealing with cooling problems or electrical malfunctions, these tips will help you address the issue efficiently. If you need replacements, you can easily find the right Turbo Air parts to ensure your fridge runs smoothly again.

| Table of the contents: Understanding Turbo Air Parts Common Signs Your Turbo Air Refrigerator Needs Troubleshooting Turbo Air Refrigerator Troubleshooting Steps When to Replace Turbo Air Refrigerator Parts Preventive Maintenance Tips for Long-Term Performance How to Read Turbo Air Error Codes Effectively |

Understanding Turbo Air Parts

Understanding the fundamental components of your Turbo Air refrigerator is fundamental for troubleshooting together with maintenance activities. The appliance operates efficiently through the essential function of every component.

|

Parts |

Description |

Common issues |

Functions |

|

Compressor |

The compressor circulates refrigerant throughout the system. |

Overheating, noise, failure to start. |

It is the heart of the refrigeration cycle, maintaining cooling. |

|

Condenser Coils |

These coils release heat absorbed by the refrigerant. |

Dust buildup, clogging, inefficient cooling. |

Help expel heat from the refrigerant, maintaining proper temperature. |

|

Evaporator Coil |

Located inside the fridge, they absorb heat to cool the air. |

Ice buildup, clogging, poor cooling performance. |

Facilitates heat absorption and cooling of the fridge interior. |

|

Thermostat |

Regulates the fridge’s internal temperature. |

Inaccurate temperature readings, failure to maintain cooling. |

Controls the temperature by turning the compressor on and off. |

|

Defrost Heater |

Helps melt frost buildup on the evaporator coils. |

Failure to defrost, ice accumulation. |

It prevents frost from building up, ensuring the fridge functions correctly. |

|

Fan |

Circulates air throughout the fridge to ensure even cooling. |

Malfunctioning motor, lack of airflow. |

Ensures even temperature distribution and proper ventilation. |

Need reliable parts for your refrigerator? PartsFe provides top-quality replacements from brands including Turbo Air, True, Whirlpool, and Wells. Whether it’s a compressor, evaporator fan, thermostat, or condenser coil, we’ve got you covered with the best parts at great prices!

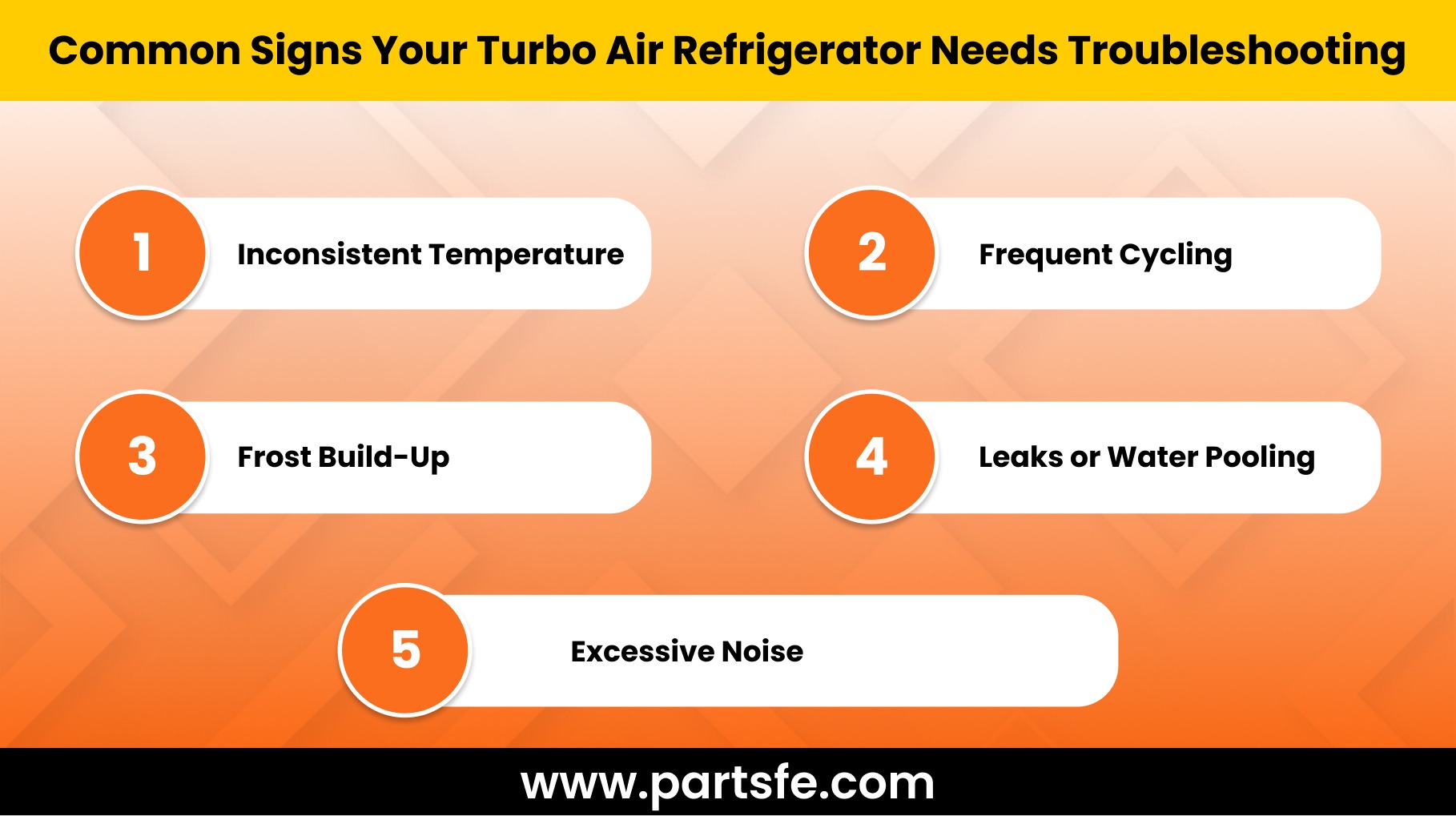

Common Signs Your Turbo Air Refrigerator Needs Troubleshooting

Your Turbo Air refrigerator requires immediate attention when it displays malfunction symptoms to avoid expensive maintenance costs and ensure longer operation. The following signs indicate your refrigerator requires troubleshooting:

-

Inconsistent Temperature: A refrigerator that fails to reach proper cold temperatures will cause food spoilage and create warm areas inside the unit. The compressor, together with the thermostat and evaporator coils, might be responsible for any observed malfunction.

-

Excessive Noise: The fan motor or compressor along with the fan could be damaged when you hear unusual or loud buzzing or grinding sounds. Check the fan operation of your M3 Turbo Air freezer because improper fan operation leads to noise.

-

Frequent Cycling: Your refrigerator performs frequent on-off cycles when its issues lie within defrost system components or thermostat mechanisms. Such operation puts excessive stress on the appliance while simultaneously increasing its energy usage. M3 Turbo Air refrigerators sometimes experience this particular issue.

-

Frost Build-Up: Freezer coils or evaporator with heavy frost accumulation indicates problems with the defrost timer, heater or thermostat. The issue will decrease cooling performance while simultaneously harming internal parts.

-

Leaks or Water Pooling: Your refrigerator shows signs of water pooling inside or around its compartment, which might be caused by blocked drainage lines or a faulty door seal. The two problems require immediate inspection to stop additional damage and inefficiency. Check if your freezer door won’t close all the way, as this can lead to water leakage.

Contact a professional or perform troubleshooting steps when you notice these symptoms to guarantee proper operation of your Turbo Air ac unit.

Check out this article Continental Refrigerator Troubleshooting guide if you're noticing issues with your refrigerator. Troubleshooting early can save you time and money.

Turbo Air Refrigerator Troubleshooting Steps

A step-by-step approach to fixing Turbo Air refrigerator problems will help you determine the source of the issue and find a solution. Follow these essential steps to resolve the issue.

Step 1: Power Issue

The refrigerator fails to start properly and maintains an improper temperature.

Solution:

Check that the refrigerator receives proper power connection and confirm the outlet operates correctly. Check both the circuit breaker and fuse box for electrical problems when your fridge fails to receive power. The M3 Turbo Air refrigerator requires the same attention to power issues.

Step 2: Incorrect Thermostat Setting

Refrigerator not cooling enough.

Solution: Check the thermostat setting is correct to solve the cooling problems. The refrigerator fails to cool efficiently when the thermostat setting is too high. Set the thermostat to a lower temperature to check if the cooling performance improves.

Step 3: Dirty Condenser Coils

Refrigerator overheating or poor cooling.

Solution: Condenser coils that accumulate dust and dirt will lead to overheating problems and reduced cooling performance. Turn off the refrigerator then use a vacuum or coil brush to clean the coils carefully. The Turbo Air reach in freezer performance might be affected by this issue.

Step 4: Frost Buildup

Ice accumulates inside the fridge or freezer compartment.

Solution: Your defrost heater or fan needs inspection because frost formation on evaporator coils indicates a possible malfunction. Check the heater and fan for damage after defrosting the coils. Your M3 Turbo Air freezer might encounter this problem often.

Step 5: Faulty Door Seal

The refrigerator loses cold air through its exterior.

Solution: The refrigerator will need to work harder because a damaged door seal lets cool air escape. Perform an inspection for tears or cracks on the seal before deciding to replace it.

Step 6: Fan or Compressor Malfunction

Refrigerator not cooling or noisy.

Solution: Check for the operating noise of the fan. A motor replacement might be necessary when the motor fails to operate. Verify that the compressor activates because it functions as a key component for cooling operations.

When to Replace Turbo Air Refrigerator Parts

The correct timing for part replacement in Turbo Air refrigerators determines both their operational quality and their overall durability. The following signs indicate your Turbo Air refrigerator needs component replacement:

-

Compressor: Your refrigerator needs replacement when it fails to cool properly after troubleshooting and the compressor produces strange loud noises. A faulty compressor usually needs replacement because repair costs exceed the replacement value.

-

Condenser Coils: The condenser coils need replacement when cleaning them fails to improve cooling or when they show significant damage or corrosion. The refrigerator operates less efficiently when its coils become worn out.

-

Evaporator Coils: The defrost system or the evaporator coils themselves may be failing when frost accumulates excessively on the coils and fails to disappear after defrosting. The system requires replacement under these conditions.

-

Thermostat: A faulty thermostat will need replacement because adjusting the temperature settings fails to fix the fridge's temperature problems.

-

Fan: A replacement fan might be necessary when insufficient airflow occurs because the fan stops working. A defective fan system reduces the fridge's ability to maintain proper temperature.

-

Door Seal: A door seal replacement is necessary when it shows cracks or tears or fails to create a proper seal because this prevents cold air loss and enhances energy efficiency.

The replacement of defective components at the right time helps protect your Turbo Air refrigerator from additional damage while maintaining peak operational performance.

Preventive Maintenance Tips for Long-Term Performance

Your Turbo Air refrigerator will function efficiently for many years by performing proper preventive maintenance. The following guidelines will help you maintain your Turbo Air refrigerator for long-term operation:

-

Clean the Condenser Coils Regularly: The buildup of dust and dirt on condenser coils makes your refrigerator heat up excessively while reducing its operational efficiency. Regular coil cleaning should be performed every 3-6 months using a vacuum or coil brush equipment to achieve maximum cooling performance.

-

Check and Replace Door Seals: The door seals function to stop cold air from leaking out of the unit. Regular checks should be performed to detect any damage in the door seals. The internal temperature remains stable when you replace damaged seals because this prevents energy loss.

-

Defrost the Fridge Regularly: The accumulation of excessive frost creates a problem that reduces cooling performance. You should perform regular defrosting of freezer and fridge compartments when needed, particularly when the evaporator coils develop ice buildup quickly.

-

Level the Refrigerator: A level refrigerator position allows proper airflow and cooling operation. The improper level of a refrigerator can shorten the lifespan of its components, which results in expensive maintenance costs.

-

Maintain the Correct Temperature Settings: The optimal fridge temperature range should be 37°F to 40°F, while the freezer needs to operate at 0°F. The combination of desired food freshness with power consumption economy becomes possible at optimal temperatures.

-

Inspect and Clean the Fan: The fan operates as the key component which distributes cold air throughout the system. Regular cleaning and smooth operation of the fan system will help prevent airflow problems caused by dust accumulation.

Contact Turbo Air customer service whenever you need help with your product. Regular maintenance of your refrigerator according to these guidelines will improve both its operational life and performance quality.

For more insights on maintenance practices, check out How Victory Refrigeration is Redefining Refrigeration Standards.to ensure your refrigeration systems stay efficient.

How to Read Turbo Air Error Codes Effectively

The correct interpretation of Turbo Air refrigerator error codes enables users to identify and fix their refrigerator problems more efficiently. Error codes help identify particular issues which enable you to save money on repair costs and reduce repair time. The following procedure shows you how to interpret Turbo Air error codes correctly:

Locate the Error Code Display

The digital screen or control panel of Turbo Air refrigerators shows error codes to users. Become familiar with the location of error codes since quick detection is vital.

Refer to the User Manual

The user manual includes an error code list with corresponding meanings. The manual should be accessible because it contains essential information about decoding various error codes.

Common Error Codes

-

E1: A temperature sensor failure might need replacement of the sensor.

-

E2: The evaporator fan shows an error code that indicates either a fan or motor failure.

-

E3: The defrost system fails to operate correctly when the defrosting sensor experiences a failure.

-

E4: Temperature control failure usually results from problems with the thermostat or control board.

Resetting the System

Certain error codes appear only during short periods or after power surges. To fix this problem users should unplug their refrigerator for several minutes before reconnecting it to the power source. The M3 Turbo Air refrigerator reset button enables users to reset their system directly to resolve temporary errors when used with this model.

Seek Professional Help

Reach out to a professional technician for help with complex error codes which do not resolve after a reset because they can protect the appliance from further damage. Contact Turbo Air tech support for professional help when you need assistance with diagnosing and fixing advanced problems affecting your refrigerator.

Your refrigerator's efficiency and expensive maintenance costs can be prevented by quick error code responses.

Also, check out our Electrolux Refrigerator Error Troubleshooting Guide to understand how reading Turbo Air error codes is crucial for efficient troubleshooting.

The correct understanding and methodical approach makes it possible to handle both maintenance and troubleshooting tasks on your Turbo Air commercial refrigerator. Reading about essential components combined with recognizing early warning signs and performing cleaning of condenser coils and door seal examination and defrost work together to stop small problems from becoming bigger issues. Operating regular maintenance on this equipment guarantees peak performance and raises both operational duration and financial savings by reducing repair expenses.

Instant action should be taken when you encounter complex problems in your appliance. Washing problems can often be solved by basic troubleshooting yet some problems will need either new parts or expert assistance for resolution. Error codes should be studied along with proper responses to help you identify appliance problems early. Any problems beyond fix-it-yourself jobs need an immediate call to a trained appliance specialist. Proactive maintenance combined with swift service repairs will guarantee your Turbo refrigerator lasts efficiently throughout several years.

FAQs

What happens when a refrigerator compressor fan fails?

When the compressor fan fails, the fridge may overheat, leading to improper cooling. This can cause the compressor to work harder, potentially leading to further damage.

Why is my Turbo Air refrigerator not cooling?

A Turbo Air refrigerator may not cool due to issues with the thermostat, condenser coils, or the compressor. It's essential to check these components for damage or dirt buildup.

What does turbo cooling mean in a refrigerator?

Turbo cooling in a refrigerator refers to a feature that rapidly lowers the temperature in the fridge or freezer. This helps quickly cool down newly stored food or beverages.

How to reset the compressor on a refrigerator?

To reset the compressor, unplug the refrigerator for a few minutes, then plug it back in. This can help resolve minor electrical or power issues affecting the compressor.