What Is a Pilot Light in Commercial Kitchen Equipment and How Does It Work?

Pilot lights are small, constantly burning flames found in many types of commercial kitchen equipment, including gas ovens, fryers, and boilers. They serve as the ignition source for the main burner, ensuring that the appliance can start safely and efficiently whenever needed. A properly functioning gas oven pilot light is crucial for reliable operation and helps prevent gas buildup, making it an essential safety feature in any commercial kitchen environment.

Understanding how a commercial gas pilot light works helps kitchen staff and maintenance teams operate appliances safely and troubleshoot minor issues before they become serious problems. By knowing their function and proper care, businesses can ensure reliable performance, reduce energy waste, and maintain a safe cooking environment.

Understanding the Pilot Light in Commercial Restaurant Equipment

Pilot lights are continuously burning gas flames in commercial kitchen appliances that ensure instant ignition and maintain commercial kitchen gas safety, even during power outages.

-

Fail‑Safe Mechanism: Many systems include a safety sensor, such as a thermocouple for commercial equipment, that cuts off the gas if the pilot flame goes out, protecting against leaks.

-

Works Without Electricity: Unlike electric ignitions, pilot lights stay lit even during power failures.

-

Constant Fuel Use: The always-on flame burns gas continuously, increasing operating cost and energy consumption over time.

-

Heat & Emissions: The flame generates ambient heat and emissions, which can affect kitchen air quality and energy usage.

-

Maintenance Indicator: A flickering or weak flame often signals a dirty burner, misaligned sensor, or gas pressure issue — a useful warning to service the equipment.

By being aware of these lesser-known aspects, restaurant operators can better balance safety, efficiency, and operating costs when using pilot‑light equipment.

Looking to fix your commercial kitchen pilot light issues? At PartsFe, we offer high-quality replacement parts like pilot assemblies, thermocouples, and ignition components from leading manufacturers like Pitco, Royal Range, and Jade Range to ensure your appliances ignite safely and efficiently. Get your ovens, fryers, grills, and griddles back to optimal performance quickly!

Types of Pilot Lights Used in Commercial Kitchen Appliances

Understanding the types of pilot lights is important for choosing the right setup in commercial kitchen appliances. They help ensure smooth startup and continuous operation of gas-powered equipment.

|

Type of Pilot Light |

Function |

Advantages |

Common Appliances |

|

Standing Pilot Light |

Remains continuously lit, ready to ignite the appliance at any time. |

Immediate ignition, Simple and reliable, Works during power outages |

Gas ovens, ranges, cooktops, deep fryers, griddles, grills |

|

Intermittent Pilot Light |

Ignites only when the appliance is turned on. |

Saves gas, Safer than standing pilot, Lower operating costs |

Gas ovens, ranges, cooktops, deep fryers, griddles |

|

Electronic Ignition Pilot |

Uses an electric spark to ignite the burner, with no constant flame. |

Energy-efficient, Safer with no constant flame, Minimal maintenance |

Broilers, salamanders, steamers, combi ovens |

|

Oven Pilot Light |

Maintains a small flame to ignite the main burner when needed. |

Provides consistent temperature control, Quick ignition |

Gas ovens |

|

Fryer Pilot Light |

Ignites the main burner beneath the oil vat. |

Ensures precise frying temperature, Fast reheating |

Deep fryers |

|

Grill Pilot Light |

Ensures burners ignite immediately and maintain steady flame. |

Supports controlled searing, Reliable ignition |

Gas grills |

|

Griddle Pilot Light |

Ignites burners beneath flat-top cooking surfaces. |

Maintains even heat distribution, reduces cooking delays |

Griddles |

Explore thermocouples for commercial equipment, including types, functions, installation, and maintenance.

How a Pilot Light Works Inside Commercial Gas Equipment

Inside commercial gas equipment, the pilot light enables commercial gas range ignition for safe, efficient, and consistent burner operation.

-

The pilot light acts as a constant ignition source, ensuring the main burner ignites immediately when gas flows (gas burner ignition system).

-

Located strategically near the main burner, it provides precise flame positioning for reliable ignition.

-

Modern pilot systems often use a thermocouple or flame sensor to detect the presence of the flame and allow safe gas flow.

-

If the flame extinguishes, the sensor automatically shuts off the gas supply, preventing leaks or hazards.

-

In intermittent or electronic systems, the pilot only ignites when the appliance is activated, reducing energy and gas waste

-

The pilot flame also preheats the gas pathway, ensuring a smoother and more stable main flame ignition.

Regular pilot light flame adjustment prevents soot, clogging, and delayed ignition in high-volume kitchens.

Common Pilot Light Issues in Commercial Restaurant Equipment

Commercial gas pilot lights are vital for the safe and efficient operation of commercial appliances, as even minor issues can disrupt kitchen workflow.

Pilot Flame Won’t Stay Lit

The pilot flame extinguishes immediately after lighting.

Possible Causes: A weak thermocouple, debris in the pilot orifice, or a draft near the appliance.

Signs: Signs of pilot flame won’t stay lit include the flame going out repeatedly and a brief smell of gas when attempting to light the pilot.

Fixes: Clean the pilot assembly thoroughly to remove dirt, soot, or debris, and ensure there is no airflow interference. Replace the thermocouple if it shows signs of wear or damage.

Pilot Flame Is Too Weak or Flickering

Flame burns unevenly or is barely visible.

Possible Causes: Low gas pressure, partially blocked pilot tube, or faulty gas regulator.

Signs: Signs of a pilot flame is too weak or flickering appear when the flame is yellow or irregular, and ignition of the main burner is delayed.

Fixes: Adjust the gas pressure to the manufacturer’s specifications and clean the pilot tube to remove any partial blockages. If the gas regulator is faulty or inconsistent, replace it to ensure a steady, strong flame.

Pilot Light Ignites but Main Burner Fails

The pilot works, but the main burner does not light.

Possible Causes: Faulty flame sensor, clogged burner ports, or improper alignment of the pilot flame.

Signs: Signs of pilot light ignites, but main burner fails include the pilot remaining steady while the main burner fails to ignite, resulting in low cooking temperature.

Fixes: Realign the pilot flame so it properly contacts the burner’s flame sensor and clean the burner ports thoroughly. Replace the flame sensor if it is defective to restore proper ignition of the main burner.

Intermittent Ignition in Electronic Pilots

Electronic ignition activates inconsistently.

Possible Causes: Loose wiring, moisture in the ignition module, or worn electrodes.

Signs: Signs of intermittent ignition in electronic pilots include sporadic sparks and the appliance requiring multiple attempts to start.

Fixes: Inspect and secure all wiring connections, and dry any moisture present in the ignition module. Replace worn or damaged electrodes to ensure consistent electronic ignition.

Pilot Light Overheating

The pilot flame appears too large or hot.

Possible Causes: High gas pressure or a malfunctioning regulator.

Signs: Signs of Pilot Light Overheating include the flame licking appliance parts, soot formation, or unusual odors.

Fixes: Reduce gas pressure to the recommended level, inspect and replace the regulator if necessary, and adjust the flame size according to manufacturer guidelines.

Pilot Tube Blockage

Gas cannot reach the pilot flame consistently.

Possible Causes: Dirt, grease, or carbon buildup inside the pilot tube.

Signs: Signs of Pilot Tube Blockage appear when the pilot flame flickers or fails to light occasionally.

Fixes: Remove the pilot tube and clean it thoroughly using compressed air or a thin wire to remove dirt, grease, or carbon buildup. Reinstall the tube properly to ensure consistent gas flow to the pilot flame.

Thermocouple Sensitivity Loss

The thermocouple fails to detect the flame accurately.

Possible Causes: Age-related wear, corrosion, or heat damage.

Signs: Signs of thermocouple sensitivity loss include the pilot light repeatedly shutting off even though the flame remains lit.

Fixes: Replace the thermocouple with a compatible model to restore accurate detection of the pilot flame. Ensure proper alignment and installation to maintain safe and continuous gas flow.

Check out common issues in commercial gas grill burners and how to fix them quickly to ensure safe, efficient, and consistent operation.

How to Troubleshoot and Fix Pilot Light Problems Safely

Pilot flame troubleshooting is essential for preventing downtime, reducing safety risks, and ensuring the smooth operation of commercial kitchen appliances.

Step 1: Observe the Flame Carefully

Step 2: Inspect for Environmental Interference

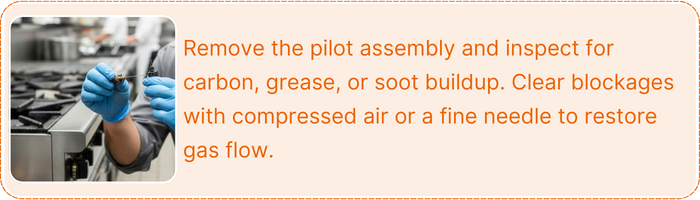

Step 3: Examine the Pilot Orifice

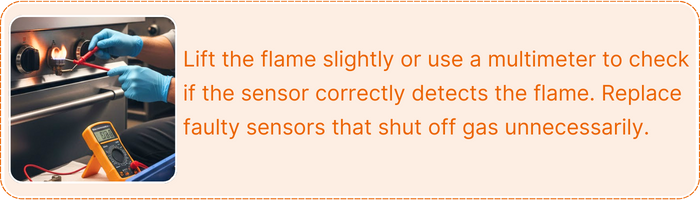

Step 4: Test the Thermocouple or Flame Sensor

Step 5: Check Gas Flow Under Operational Load

Step 6: Verify Pilot-to-Burner Alignment

Step 7: Relight Using Controlled Techniques

Safety Note: Never attempt extensive repairs on gas lines or valves unless you are a licensed professional. Incorrect handling can lead to gas leaks, fires, or explosions.

When to Call a Professional & How to Choose Quality Pilot Light Parts

Minor pilot light issues can sometimes be handled in-house, but certain signs indicate professional intervention is safer:

-

The pilot flame flickers or dies only under heavy appliance use

-

You notice inconsistent burner ignition across multiple cycles

-

Strange odors persist even after ventilation checks

-

Irregular gas pressure readings or unusual hissing sounds

Choosing Quality Parts

Opt for OEM or certified high-quality replacements. Consider heat-resistant, corrosion-proof components for commercial kitchens. Using substandard thermocouples, pilot tubes, or orifices can reduce efficiency, cause frequent misfires, and even pose hidden safety hazards over time.

Best Practices for Maintaining Pilot Lights in Commercial Kitchens

Pilot light maintenance is essential to prevent safety hazards and efficiency issues. Regular checks catch hidden problems before they escalate.

Regular checks catch hidden problems before they escalate.

-

Check for Micro-Vibrations: In high-traffic kitchens, vibrations from heavy equipment can loosen pilot assemblies or cause a slight misalignment of the flame over time.

-

Inspect Condensation or Moisture Accumulation: Steam from ovens, kettles, or dishwashers can condense near pilot components, causing corrosion or inconsistent ignition.

-

Monitor Pilot Tube Length and Position: Over time, repeated servicing or accidental knocks can slightly shift the pilot tube, reducing flame contact with sensors.

-

Detect Gas Line Fatigue: Small kinks or stress in flexible gas lines feeding the pilot can reduce flow intermittently—these are often invisible during routine checks.

-

Observe Heat-Cycle Wear: Repeated rapid heating and cooling can degrade pilot materials, especially in high-use appliances like broilers or fryers.

Focusing on these subtle factors ensures longer pilot life, safer operation, and fewer unexpected shutdowns.

Conclusion: Ensuring Safe and Consistent Ignition in Commercial Kitchens

Proper care and monitoring of pilot lights are essential for smooth, safe kitchen operations. Early detection of subtle issues prevents downtime, reduces energy waste, and minimizes hidden safety risks. Consistent practices and quality components ensure long-term performance.

Key Takeaways:

-

Small flickers, inconsistent flame height, or faint odors often indicate larger hidden problems.

-

Airflow, nearby heat sources, or high humidity can subtly affect pilot performance over time.

-

Monitoring how long thermocouples, pilot tubes, and orifices have been in service helps anticipate replacements before failures.

-

A slightly misaligned or weak pilot can reduce burner efficiency, increasing energy costs unnoticed.

-

Logging patterns over weeks or months can reveal recurring stress factors that quick fixes overlook.

-

Heavy-duty appliances in proximity can create vibrations or drafts that subtly impact pilot stability

Pilot lights may appear minor, but their performance directly impacts safety and kitchen efficiency. Tracking subtle irregularities and environmental influences helps prevent hidden issues before they escalate. Consistent maintenance, quality parts, and careful observation ensure uninterrupted, safe operation in busy commercial kitchens.

FAQs

How do I light a pilot on a commercial stove?

To light a commercial stove pilot, locate the pilot assembly and turn the gas valve to the pilot position. Press and hold the igniter or use a lighter until the flame stays steady.

Can I relight the pilot light by myself?

Yes, you can relight it if you follow the manufacturer’s safety instructions and ensure there is no gas smell. If the flame won’t stay lit, it’s safer to call a technician.

Why is my commercial stove pilot not lighting?

A blocked pilot orifice, faulty thermocouple, or low gas pressure can prevent the pilot from lighting. Inspect these components or contact a service professional if the issue continues.